Data sheet, Feature descriptions – GE Industrial Solutions QBVE078A0S10R4 Barracuda Series User Manual

Page 8

GE

Data Sheet

QBVE078A0S10R4 Barracuda Series; DC-DC Converter Power Modules

45-56Vdc Input; 10.4Vdc, 78.0A, 810W Output

January 15, 2014

©2012 General Electric Company. All rights reserved.

Page 8

Feature Descriptions

Overcurrent Protection

To provide protection in a fault output overload condition,

the module is equipped with internal current-limiting

circuitry and can endure current limiting continuously. If the

overcurrent condition causes the output voltage to fall

greater than 3.0V from V

o,set

, the module will shut down and

remain latched off. The overcurrent latch is reset by either

cycling the input power or by toggling the on/off pin for one

second. If the output overload condition still exists when the

module restarts, it will shut down again. This operation will

continue indefinitely until the overcurrent condition is

corrected.

A factory configured auto-restart option (with overcurrent

and overvoltage auto-restart managed as a group) is also

available. An auto-restart feature continually attempts to

restore the operation until fault condition is cleared.

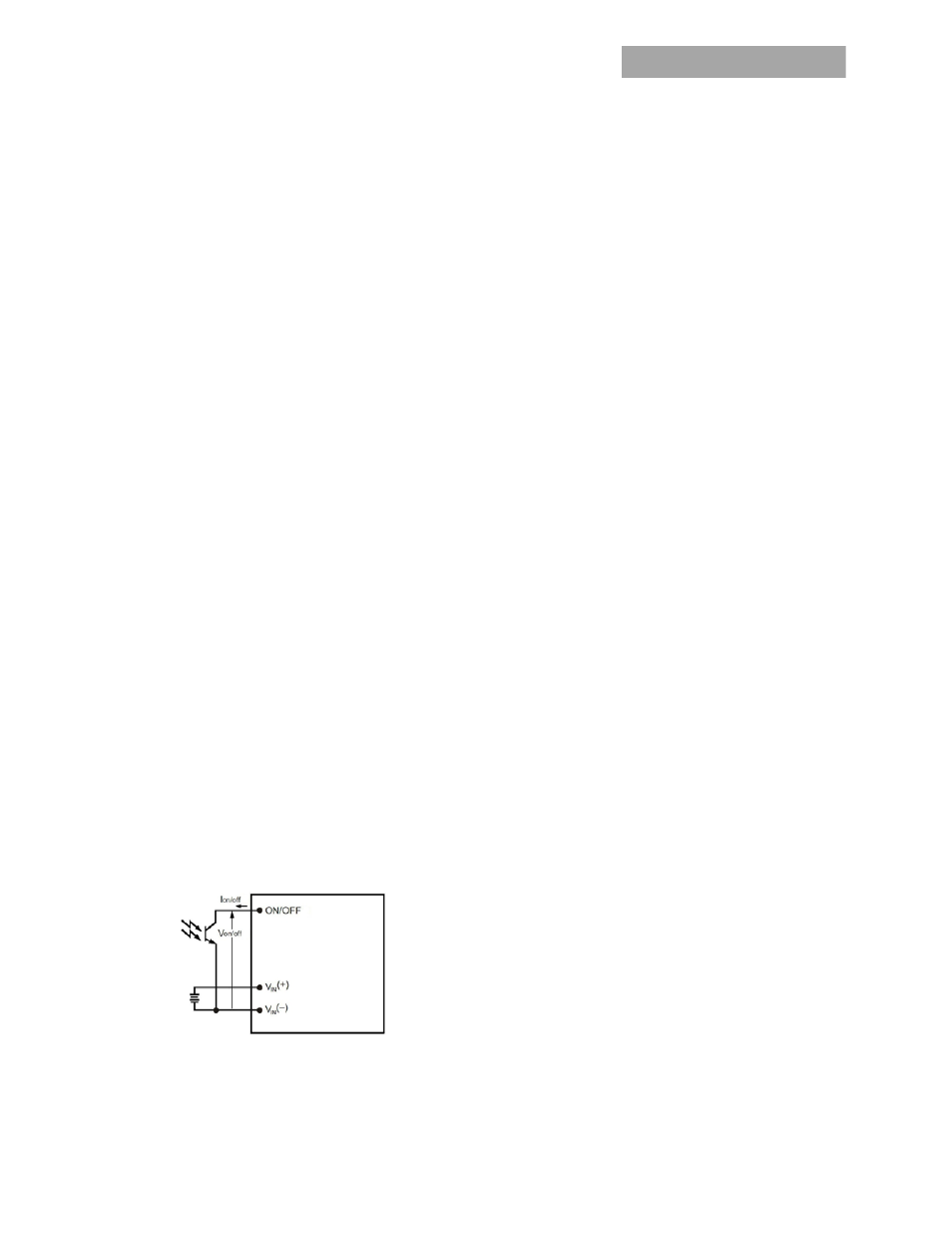

Remote On/Off

The module contains a standard on/off control circuit

reference to the V

IN

(-) terminal. Two factory configured

remote on/off logic options are available. Positive logic

remote on/off turns the module on during a logic-high

voltage on the ON/OFF pin, and off during a logic low.

Negative logic remote on/off turns the module off during a

logic high, and on during a logic low. Negative logic, device

code suffix "1," is the factory-preferred configuration. The

On/Off circuit is powered from an internal bias supply,

derived from the input voltage terminals. To turn the power

module on and off, the user must supply a switch to control

the voltage between the On/Off terminal and the V

IN

(-)

terminal (V

on/off

). The switch can be an open collector or

equivalent (see Figure 14). A logic low is V

on/off

= -0.3V to 0.8V.

The typical I

on/off

during a logic low (Vin=48V, On/Off

Terminal=0.3V) is 147µA. The switch should maintain a logic-

low voltage while sinking 200µA. During a logic high, the

maximum V

on/off

generated by the power module is 8.2V. The

maximum allowable leakage current of the switch at V

on/off

=

2.4V is 130µA. If using an external voltage source, the

maximum voltage V

on/off

on the pin is 14.5V with respect to

the V

IN

(-) terminal.

If not using the remote on/off feature, perform one of the

following to turn the unit on:

For negative logic, short ON/OFF pin to V

IN

(-).

For positive logic: leave ON/OFF pin open.

Figure 14. Remote On/Off Implementation.

Output Overvoltage Protection

The module contains circuitry to detect and respond to

output overvoltage conditions. If the overvoltage condition

causes the output voltage to rise above the limit in the

Specifications Table, the module will shut down and remain

latched off. The overvoltage latch is reset by either cycling

the input power, or by toggling the on/off pin for one

second. If the output overvoltage condition still exists when

the module restarts, it will shut down again. This operation

will continue indefinitely until the overvoltage condition is

corrected.

A factory configured auto-restart option (with overcurrent

and overvoltage auto-restart managed as a group) is also

available. An auto-restart feature continually attempts to

restore the operation until fault condition is cleared.

Overtemperature Protection

These modules feature an overtemperature protection

circuit to safeguard against thermal damage. The circuit

shuts down the module when the maximum device

reference temperature is exceeded. The module will

automatically restart once the reference temperature cools

by ~25°C.

Input Under/Over voltage Lockout

At input voltages above or below the input under/over

voltage lockout limits, module operation is disabled. The

module will begin to operate when the input voltage level

changes to within the under and overvoltage lockout limits.

Load Sharing

For higher power requirements, the QBVE078A0S10R4

power module offers an optional feature for parallel

operation (-P Option code). This feature provides a precise

forced output voltage load regulation droop characteristic.

The output set point and droop slope are factory calibrated

to insure optimum matching of multiple modules’ load

regulation characteristics. To implement load sharing, the

following requirements should be followed:

The V

OUT

(+) and V

OUT

(-) pins of all parallel modules must be

connected together. Balance the trace resistance for each

module’s path to the output power planes, to insure best

load sharing and operating temperature balance.

V

IN

must remain between 45V

dc

and 56V

dc

for droop

sharing to be functional.

It is permissible to use a common Remote On/Off signal to

start all modules in parallel.

These modules contain means to block reverse current

flow upon start-up, when output voltage is present from

other parallel modules, thus eliminating the requirement

for external output ORing devices. Modules with the –P

option may automatically increase the Turn On delay, T

delay

,

as specified in the Feature Specifications Table, if output

voltage is present on the output bus at startup.

When parallel modules startup into a pre-biased output,

e.g. partially discharged output capacitance, the T

rise

is

automatically increased, as specified in the Feature

Specifications Table, to insure graceful startup.

Insure that the total load is <50% I

O,MAX

(for a single module)

until all parallel modules have started (load full start >

module T

delay

time max + T

rise

time).

If fault tolerance is desired in parallel applications, output

ORing devices should be used to prevent a single module

failure from collapsing the load bus.