Thermal considerations, Heat transfer without heat sinks, Lineage power 11 – GE Industrial Solutions QW030xx DUAL Series User Manual

Page 11: Continued), 48 v i, 5 a, i, 5 a t, 89 °c determine p, Use figure 9): p, Figure 8. qw030bk power derating curve

Lineage Power

11

Data Sheet

October 2008

18 Vdc to 36 Vdc or 36 Vdc to 75 Vdc Inputs

QW030xx DUAL Series Power Modules: dc-dc Converters;

Thermal Considerations

(continued)

Heat Transfer Without Heat Sinks

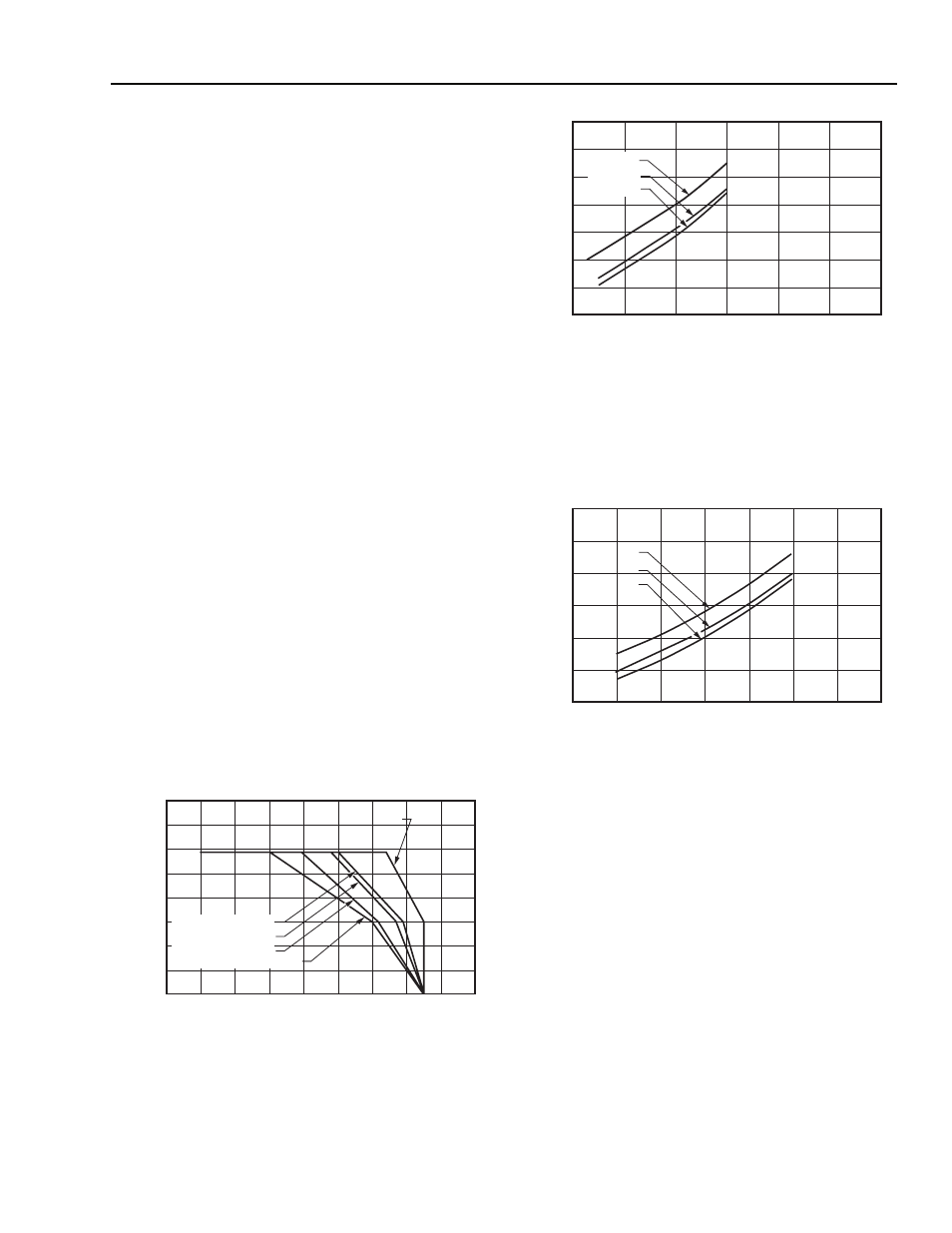

Increasing airflow over the module enhances the heat

transfer via convection. Figures 8 and 10 show the

maximum power that can be dissipated by the module

without exceeding the maximum case temperature ver-

sus local ambient temperature (T

A

) for natural convec-

tion through 3 m/s (600 ft./min.).

Systems in which these power modules may be used

typically generate natural convection airflow rates of

0.3 ms

–1

(60 ft./min.) due to other heat-dissipating com-

ponents in the system. Therefore, the natural convec-

tion condition represents airflow rates of up to 0.3 ms

–1

(60 ft./min.). Use of Figure 8 is shown in the following

example.

Example

What is the minimum airflow necessary for a

QW030BK operating at V

I

= 48 V, an output current of

1.5 A, each and a maximum ambient temperature of 89

°C?

Solution

Given: V

I

= 48 V

I

O1

= 1.5 A, I

O2

= 1.5 A

T

A

= 89 °C

Determine P

D

(Use Figure 9):

P

D

= 4.5 W

Determine airflow (v) (Use Figure 8):

v = 3.0 m/s (600 ft./min.)

1-0206

Figure

8. QW030BK POWER DERATING CURVE

1-0204

Figure

9. QW030BK Power dissipation With

Balanced Loads

1-0205

Figure

10. QW030BK Power Dissipation with

Unbalanced Loads with Io1 = 0.5 A

LOCAL AMBIENT TEMPERATURE, T

A

( C)

PO

WER DISSIP

A

TION, P

D

(W)

40

50

60

70

80

90

110

100

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0.0

3.0 m/s (600 ft./min.)

2.0 m/s (400 ft./min.)

1.0 m/s (200 ft./min.)

NATURAL CONVECTION

MAX CASE TEMP.

OUTPUT CURRENT, I

O

1

=

I

O

2

(A)

PO

WER DISSIP

A

TION, P

D

(W)

0

0.5

1

1.5

2

2.5

6

5

4

3

2

1

0

V

I

= 48 V

V

I

= 36 V

V

I

= 75 V

OUTPUT CURRENT, I

O

2 (A)

PO

WER DISSIP

A

TION, P

D

(W)

0

0.5

1

1.5

2

2.5

6

5

4

3

2

1

V

I

= 48 V

V

I

= 36 V

V

I

= 75 V

3.0