Internal schematics, Figure 4. internal schematic, Application – GE Industrial Solutions FLTR100V20 Filter Module User Manual

Page 5: Data sheet march 2008

Data Sheet

March 2008

Lineage Power

5

75 Vdc Input Maximum, 20 A Maximum

FLTR100V20 Filter Module

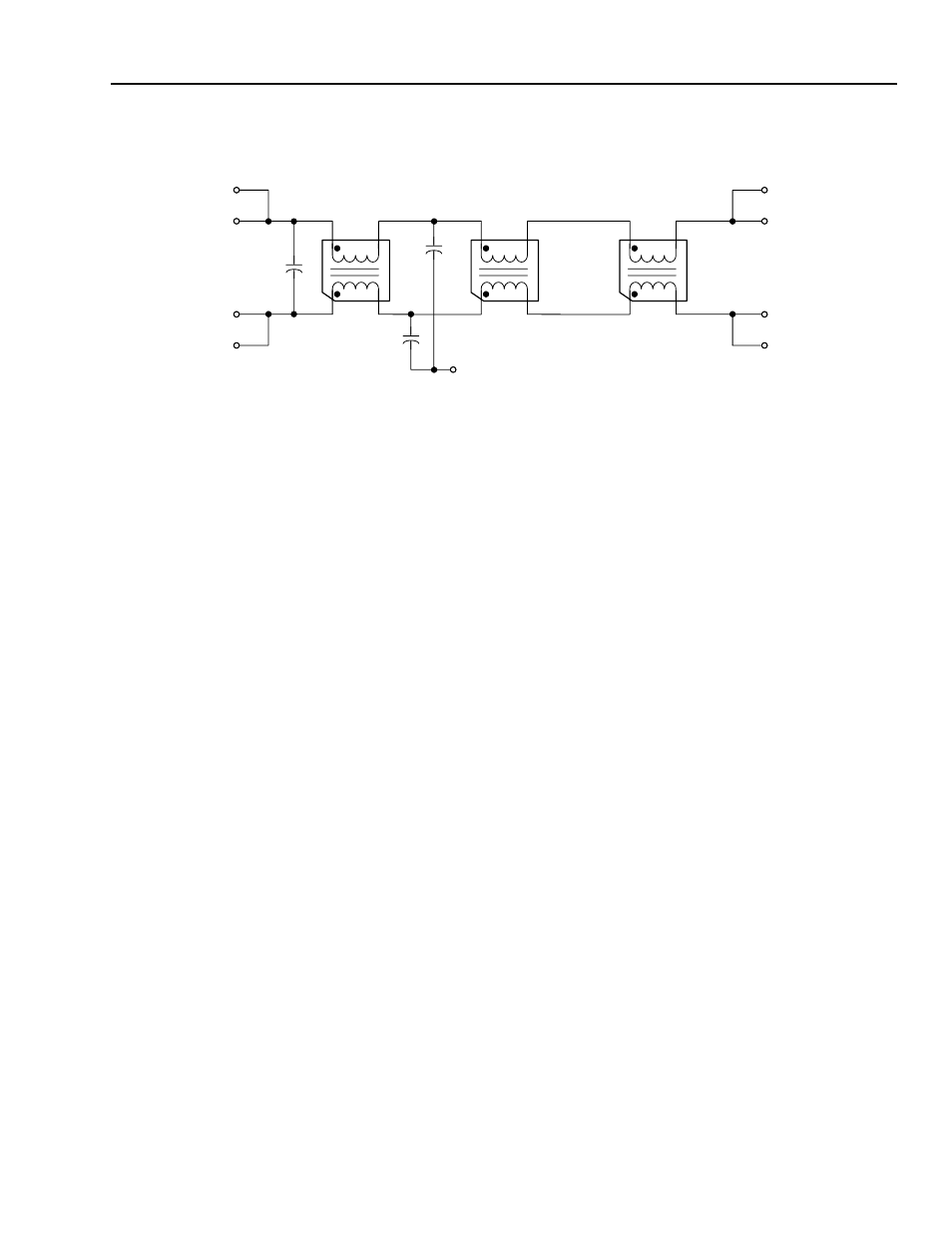

Internal Schematics

8-1324a

Figure 4. Internal Schematic

GND

V

I

(+)

V

I

(+)

V

O

V

O

V

I

(-)

V

I

(-)

V

O

V

O

(+)

(+

(-

(-

Application

Conducted noise on the input power lines can occur as

either differential-mode or common-mode noise cur-

rents. Differential-mode noise is measured between the

two input lines, and is found mostly at the low-

frequency end of the spectrum. This noise shows up as

noise at the fundamental switching frequency and its

harmonics. Common-mode noise is measured

between the input lines and ground and is mostly

broadband noise above 10 MHz. The high-frequency

nature of common-mode noise is mostly due to the

high-speed switching transitions of power train compo-

nents. Either or both types of noise may be covered in

a specification, as well as a combination of the two. An

approved measurement technique is often described,

as well.

Differential-mode noise is best attenuated using a filter

composed of line-to-line capacitors (X caps) and series

inductance, provided by either a discrete inductor or

the leakage inductance of a common-mode choke. In

addition to the differential filtering provided by the filter

module, it is recommended that an electrolytic capaci-

tor be located at the converter side of the filter to pro-

vide additional attenuation of low-frequency differential

noise and to provide a low source impedance for the

converter. This prevents input filter oscillations and

load-transient induced input voltage dips.

Common-mode noise is best attenuated by capacitors

from power module input to power module output,

capacitors from each input line to a shield plane

(Y caps), and common-mode chokes. It is recom-

mended that ceramic capacitors be added around each

power module from each input and output pin to a

shield plane under the module. The shield plane should

be connected to the CASE pin.

The GND pin of the filter module is attached to Y caps

within the module. This pin should be tied to a quiet

chassis ground point away from the power modules.

GND of the filter module should not be tied to the

CASE pin of the power module since this is a noisy

node and will inject noise into the filter, increasing the

input common-mode noise.

If no quiet grounding point is available, it is best to

leave the filter module GND pin unattached. Each

power system design will be different, and some exper-

imentation may be necessary to arrive at the best con-

figuration.

Figure 5 shows a typical schematic of a power module

with a filter module and recommended external compo-

nents. Figure 6 is a proposed layout. More than one

power module may be attached to a single filter module

as long as input current does not exceed 20 A. Figure 7

shows the recommended schematic for two power

modules attached to a single filter.

In applications where the addition of input-to-output

capacitors is undesirable, do not use C3 and C4 shown

in Figures 5 and 6, and do not use C3, C4, C8, and C9

shown in Figure 7.

In –48 V applications where the shield plane and the

power module case must be tied to a signal, remove

C1 in Figures 5 and 6, remove C1 and C6 in Figure 7,

and connect the shield plane and CASE pin to the V

I

(+)

plane.

In +48 V applications where the shield plane and the

power module case must be tied to a signal, remove

C2 in Figures 5 and 6, remove C2 and C7 in Figure 7,

and connect the shield plane and CASE pin to the V

I

(–)

plane.