Surface mount information, Austin microlynx, Pick and place – GE Industrial Solutions Austin Microlynx II SMT User Manual

Page 19: Nozzle recommendations, Tin lead soldering

Data Sheet

September 10, 2013

Austin MicroLynx

TM

II SMT Non-isolated Power Modules:

2.4 – 5.5Vdc input; 0.75Vdc to 3.63Vdc Output; 6A output current

LINEAGE

POWER

19

Surface Mount Information

Pick and Place

The Austin MicroLynx

TM

II SMT modules use an open

frame construction and are designed for a fully

automated assembly process. The modules are fitted

with a label designed to provide a large surface area

for pick and placing. The label meets all the

requirements for surface mount processing, as well as

safety standards and is able to withstand maximum

reflow temperature. The label also carries product

information such as product code, serial number and

location of manufacture.

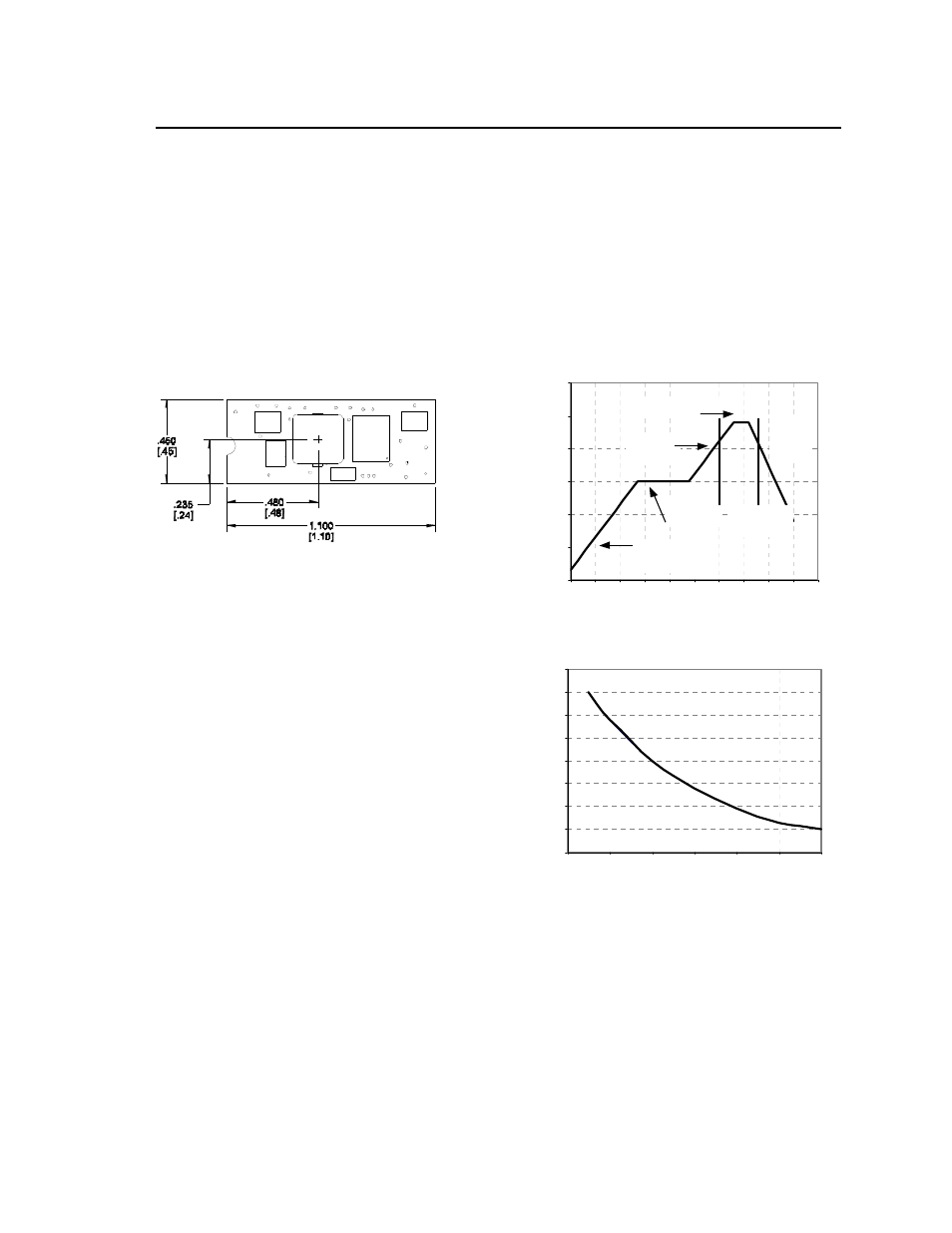

Figure 34. Pick and Place Location.

Nozzle Recommendations

The module weight has been kept to a minimum by

using open frame construction. Even so, these

modules have a relatively large mass when compared

to conventional SMT components. Variables such as

nozzle size, tip style, vacuum pressure and pick &

placement speed should be considered to optimize

this process. The minimum recommended nozzle

diameter for reliable operation is 3mm. The maximum

nozzle outer diameter, which will safely fit within the

allowable component spacing, is 8 mm max.

Tin Lead Soldering

The Austin MicroLynx

TM

II SMT power modules are

lead free modules and can be soldered either in a

lead-free solder process or in a conventional Tin/Lead

(Sn/Pb) process. It is recommended that the

customer review data sheets in order to customize the

solder reflow profile for each application board

assembly. The following instructions must be

observed when soldering these units. Failure to

observe these instructions may result in the failure of

or cause damage to the modules, and can adversely

affect long-term reliability.

In a conventional Tin/Lead (Sn/Pb) solder process

peak reflow temperatures are limited to less than

235

o

C. Typically, the eutectic solder melts at 183

o

C,

wets the land, and subsequently wicks the device

connection. Sufficient time must be allowed to fuse

the plating on the connection to ensure a reliable

solder joint. There are several types of SMT reflow

technologies currently used in the industry. These

surface mount power modules can be reliably

soldered using natural forced convection, IR (radiant

infrared), or a combination of convection/IR. For

reliable soldering the solder reflow profile should be

established by accurately measuring the modules CP

connector temperatures.

R

E

FLOW

TEM

P

(°

C)

0

50

100

150

200

250

300

Preheat zo ne

max 4

o

Cs

-1

Soak zo ne

30-240s

Heat zone

max 4

o

Cs

-1

Peak Temp 235

o

C

Co oling

zone

1-4

o

Cs

-1

T

lim

above

205

o

C

REFLOW TIME (S)

Figure 35. Reflow Profile for Tin/Lead (Sn/Pb)

process.

MAX

TE

MP

S

O

LD

E

R

(°

C)

200

205

210

215

220

225

230

235

240

0

10

20

30

40

50

60

Figure 36. Time Limit Curve Above 205

o

C for

Tin/Lead (Sn/Pb) process.