Step 1 – unpack and inspect, Step 2 – mount protective device, Step 4 – secure door ring interlock catch kit – GE Industrial Solutions Record Plus TDR Door-Ring Interlock Kit: FC100 User Manual

Page 2

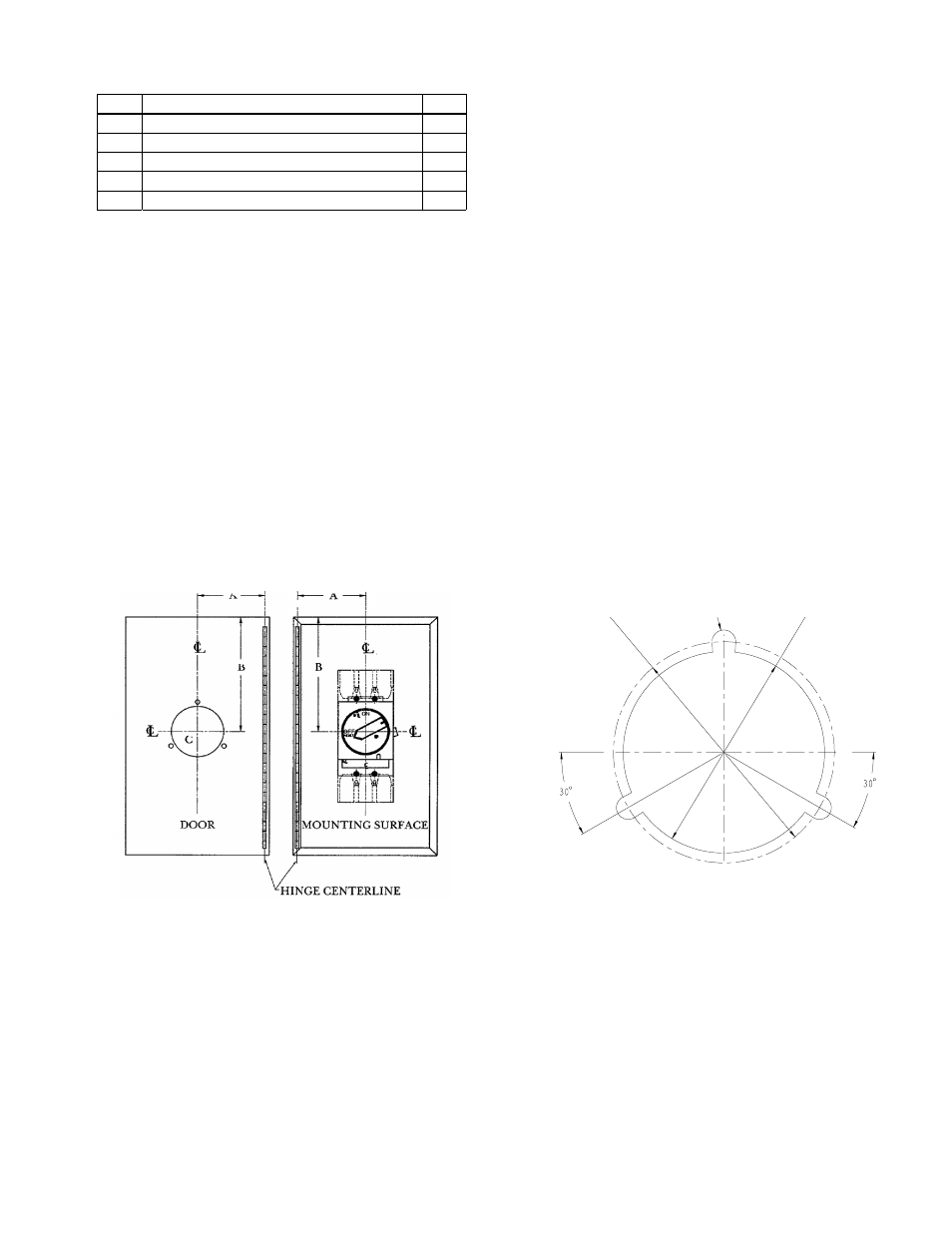

the figures refer to the item numbers in Table 1.

Item Description

Qty.

1 Interior

ring

1

2 Exterior

ring

1

3 Interlock

catch

1

4 Lockwasher

1

5 #8-32

screws

4

Table 1. List of parts in theTDR integral handle operator catch kit.

Step 1 – Unpack and Inspect

Unpack the integral handle operator kit and inspect the

parts for any shipping damage. Verify that all parts are

supplied, as listed in Error! Reference source not found..

Step 2 – Mount protective device

Locate and mount the breaker within the enclosure per

installation instructions DEH40463 for the FC100 circuit

breaker. The distance from the vertical centerline of the

protective device to the enclosure wall (with hinges) has a

minimum distance A, illustrated in Figure 2. Distance A

must be equal to or greater than one-half the length of the

enclosure door from the hinged side to the latch side.

Preferably, the hole should be located toward the latch

side for interlock leverage.

Figure 2. TDR integral handle operator catch kit.

Step 3 – Secure integral handle

operator to protective device

Mount integral handle mechanism to circuit breaker after

the breaker is secured to the enclosure according to

installation instructions DEH40914 for the FCNRC or

FCNRD TDR handle operator.

Step 4 – Secure door ring

interlock catch kit

Each kit consists of an exterior ring, interior ring,

interlock catch, and mounting hardware. The kit is

designed to assure proper door ring alignment and

interlocking. The interlock catch for the protective

device

must be secured to the interior ring with one of the #8-32

screws furnished.

A. Locate the center of a circle for the integral handle

indication ring on the enclosure door, referring to Figure

2 and the following steps.

1. Obtain distances A and B.

a. The horizontal distance from the centerline of

the indication ring centerline of the enclosure.

b. The vertical distance from the centerline of the

indication ring to the top of the enclosure.

2. Assuming the mounting surface of the enclosure

and the closed door to be parallel, transcribe

dimensions A and B to the enclosure door per figure 2.

a. Using point C as your center, scribe a circle,

diameter is 3.437” (87.3mm).

b. Cut out the circle in the enclosure door.

c. Drill three 0.406“ (10.3mm) diameter holes in

the enclosure door about a 3.812” (96.82mm)

diameter per Figure 3.

∅0.406”

∅3.437”

∅3.812”

Figure 3. Hole cutout and drill pattern.

d. Loosely secure each ring to the door with pan

head screws per Figure 4.