6 mechanical considerations, Enable 3d view – OSRAM PrevaLED Core Z3 User Manual

Page 18

18

PrevaLED

®

Core Z3 LED modules

|

Mechanical considerations

6 Mechanical considerations

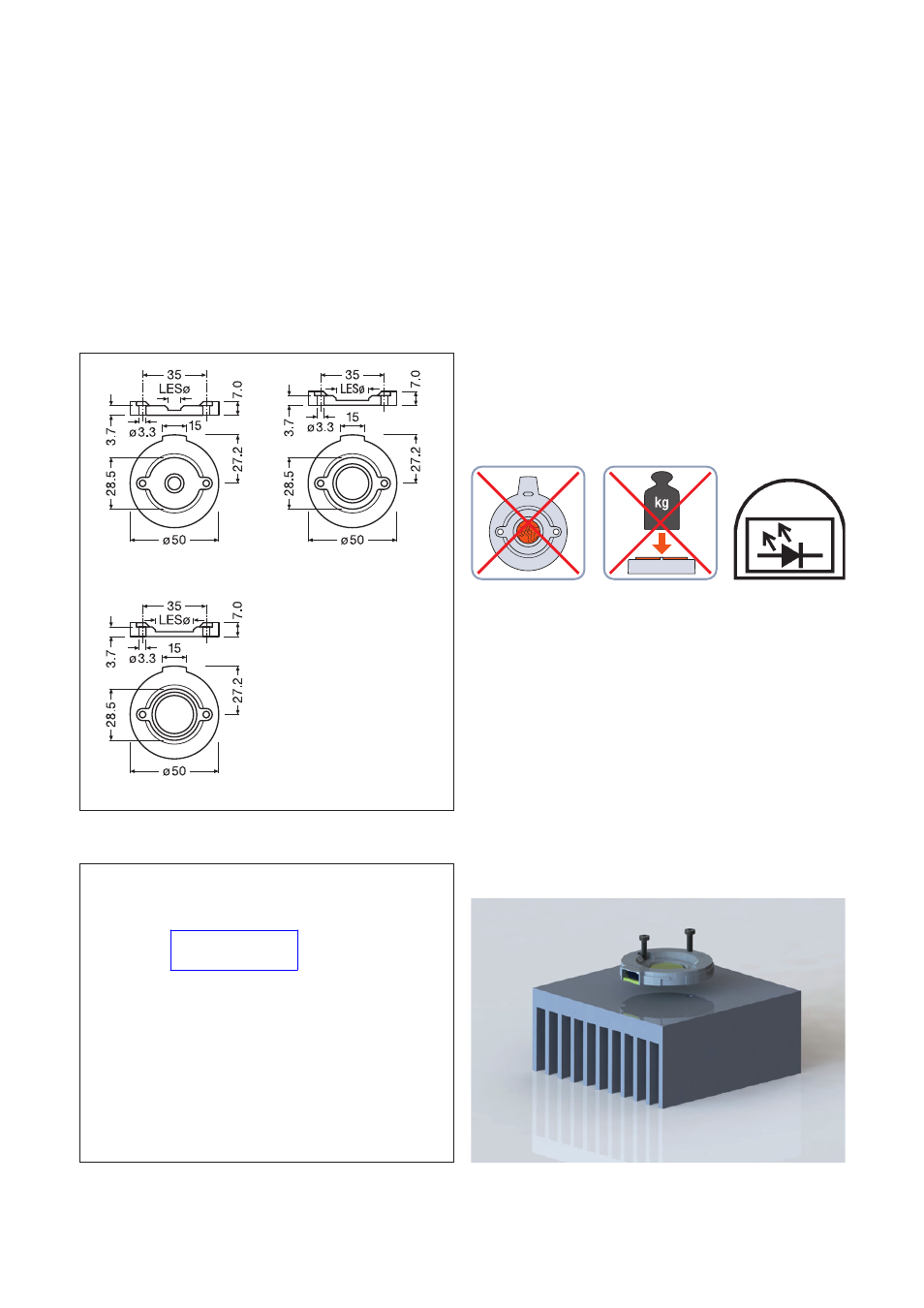

The following schematic drawing provides further details on

the dimensions of PrevaLED

®

Core Z3 LED modules. For 3D

fi les of the LED modules, please go to:

www.osram.com

.

6.1 Outline drawing

For operation in damp, wet or dusty environments, the user

has to make sure that an adequate ingress protection is

chosen. The LED module has to be protected by a suitable

IP classifi cation of the luminaire housing. Please con sider

the luminaire standard IEC 60598-1 as well as the different

requirements.

6.4 Mounting

To fi x a PrevaLED

®

Core Z3 LED module to a heat sink, you

can use M3 cylinder head screws according to DIN 7984. If

you cannot use DIN screws, please use the following speci-

fi cation: Height of head not more than 2.6 mm, diameter of

head below 5.5 mm. The allowed torque is 0.4 to 0.6 Nm.

6.3 Mechanical protection of the PrevaLED

®

Core Z3

LED module

The housing of a PrevaLED

®

Core Z3 LED module should

not be exposed to strong mechanical stress. Please apply

force only to the dedicated mounting positions. Strong me-

chanical stress can lead to irreversible damage of

the LED module.

Note: Please do not touch or mechanically stress

the yellow chip-on-board surface. This could damage

the module.

6.2 3D drawing

1100 lm

5000 lm

2000/3000 lm

Enable 3D View