4 thermal considerations – OSRAM PrevaLED Core Z3 User Manual

Page 14

14

PrevaLED

®

Core Z3 LED modules

|

Thermal considerations

Defi ne boundary

conditions

Estimate heat sink

thermal resistance on

LED module level

Select heat sink

thermal resistance

Total power dissipation of the

LED module, max. ambient

temperature t

a

, max. reference

temperature t

r

according to life-

time requirements

Use the estimated R

th

as a tar-

get for a possible heat sink

profi le and examine the perfor-

mance curve in the heat sink

manufacturer’s catalog.

R

th

=

t

r

- t

a

P

th

t

r

measured at the t

c

point

4 Thermal considerations

The proper thermal design of an LED luminaire is critical for

achieving the best performance and ensuring the longest

lifetime of all components. Due to the high effi cacy of Pre-

vaLED

®

Core Z3 LED modules, only a partial amount of the

introduced electrical power has to be dissipated through the

back of the LED module. The thermal power that has to be

dissipated for PrevaLED

®

Core Z3 LED modules is given

below.

4.1 Thermal power values

4.2 TIM and other accessories

When mounting a PrevaLED

®

Core Z3 LED module within a

luminaire, it is recommended to use thermal interface

material (TIM) between the back of the LED module and the

luminaire housing or heat sink. It is recommended to use

thermal paste, but thermal foil can also be used. In order to

balance possible unevenness, the material should be

applied as thinly as possible, but as thickly as necessary.

In this way, air inclusions, which may otherwise occur, are

replaced by TIM and the required heat conduction between

the back of the LED module and the contact surfaces of the

luminaire housing is achieved. For this purpose, the planarity

and smoothness of the surface should be optimized.

The list below is a selection of suppliers of thermal interface

materials. Additional suppliers for thermal management

support can also be found via OSRAM’s LED Light for your

network:

www.ledlightforyou.com

.

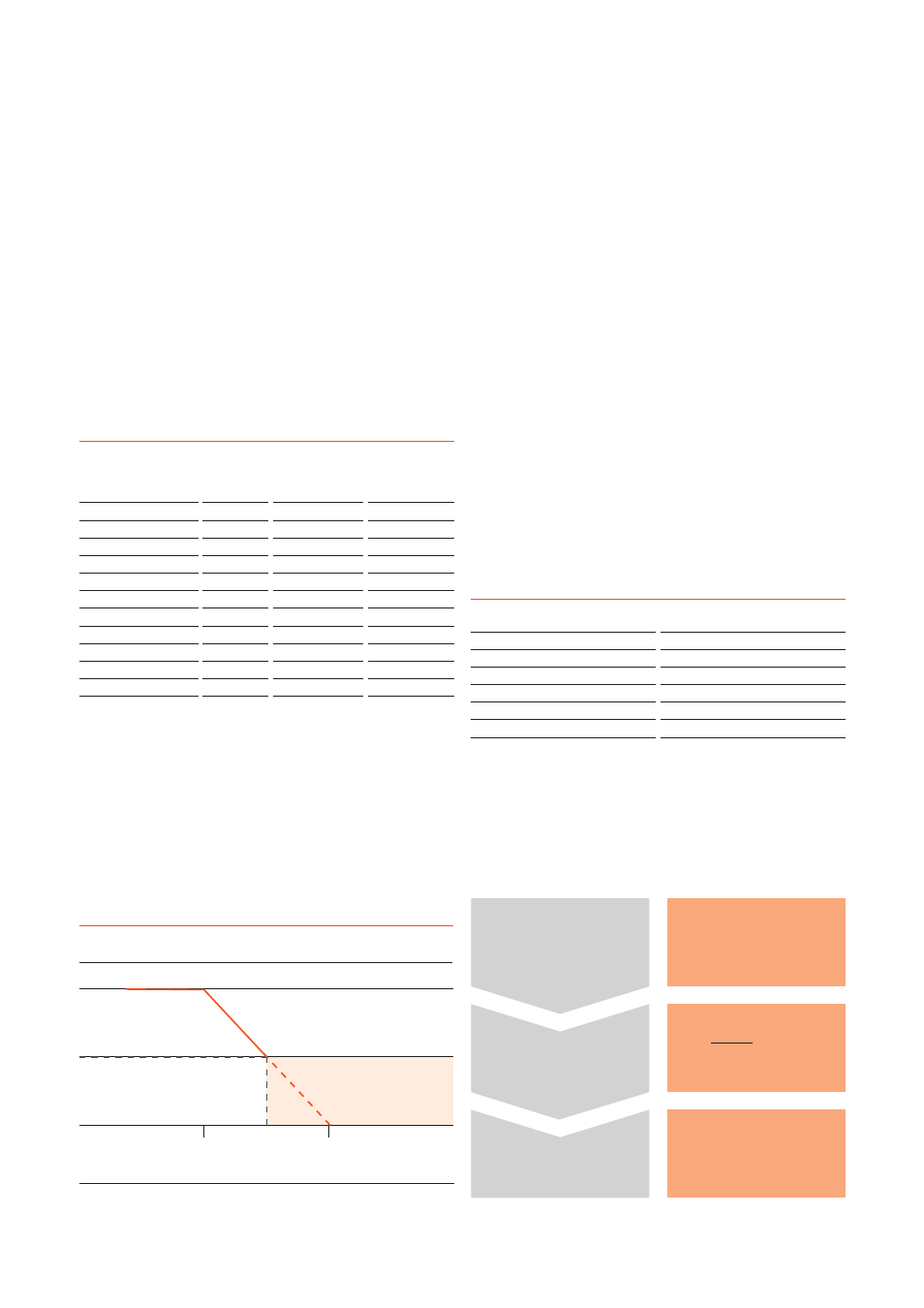

4.3 Cooling system and heat sinks

For the selection of a suitable heat sink, several points

regarding thermal resistance have to be considered.

The selection is usually done through the following

necessary steps.

To achieve the best possible lifetime of the module and to

save it from damage by overheating, a thermal protection

feature is added. This feature is only usable when operating

the module with an OSRAM OTi control gear.

The characteristics of the thermal protection are shown in

the following diagram:

Product

Typ. thermal

power [W]

1)

Max. thermal

power [W] at

nominal current

1)

Max. allowable

thermal resis-

tance R

th

[K/W]

2)

PL-CORE-1100-830-Z3

7.7

8.2

4.91

PL-CORE-1100-840-Z3

6.9

7.3

5.48

PL-CORE-2000-830-Z3

11.2

12.4

3.23

PL-CORE-2000-930-Z3

14.4

15.6

2.56

PL-CORE-2000-840-Z3

10.1

11.0

3.63

PL-CORE-3000-830-Z3

15.9

17.4

2.30

PL-CORE-3000-930-Z3

21.2

23.3

1.72

PL-CORE-3000-840-Z3

15.1

16.6

2.41

PL-CORE-5000-830-Z3

28.6

31.3

1.28

PL-CORE-5000-930-Z3

33.7

36.8

1.09

PL-CORE-5000-840-Z3

25.1

27.4

1.46

Thermal interface materials

Alfatec

www.alfatec.de

Kerafol

www.kerafol.de

Laird

www.lairdtech.com

Bergquist

www.bergquistcompany.com

Arctic Silver

www.arcticsilver.com

Wakefield

www.wakefield.com

1) Value measured at the t

c

point at a reference temperature (t

r

) of 65 °C.

2) Value measured at the rear of the luminaire at an ambient temperature

of 25 °C.

Selection of a heat sink

The behaviour below 50 % of the system current depends on the

nominal system current and the applied ECG.

t

c

[°C]

75

105

Current [% of minimal ECG current]

0

100

50