Varistor products, Clamping voltage over temperature (v, At 10a) – Littelfuse MLA Automotive Varistor Series User Manual

Page 5

© 2014 Littelfuse, Inc.

51

Revised: January 16, 2014

Varistor Products

MLA Automotive Varistor Series

Surface Mount Multilayer Varistors (MLVs) > MLA Automotive Series

Specifications are subject to change without notice.

Please refer to www.littelfuse.com/series/ML.html or MLA.html for current information.

MLA Automotive Series

Device Characteristics

At low current levels, the V-I curve of the multilayer

transient voltage suppressor approaches a linear (ohmic)

relationship and shows a temperature dependent effect.

At or below the maximum working voltage, the suppressor

is in a high resistance modex (approaching 10

6

Ω at its

maximum rated working voltage). Leakage currents at

maximum rated voltage are below 100µA, typically 25µA.

100%

1E

-9

1E

-8

SUPPRESSOR CURRENT (A

DC

)

10%

1E

-7

1E

-6

1E

-5

1E

-4

1E

-3

1E

-2

25

50

75

100

125

o

C

SUPPRESSOR

VO

LT

A

GE IN PERCENT OF

V

NOM

V

ALUE

AT

25

o

C (%)

FIGURE 10. TYPICAL TEMPERATURE DEPENDANCE OF THE CHARACTERISTIC

CURVE IN THE LEAKAGE REGION

o

o

o

o

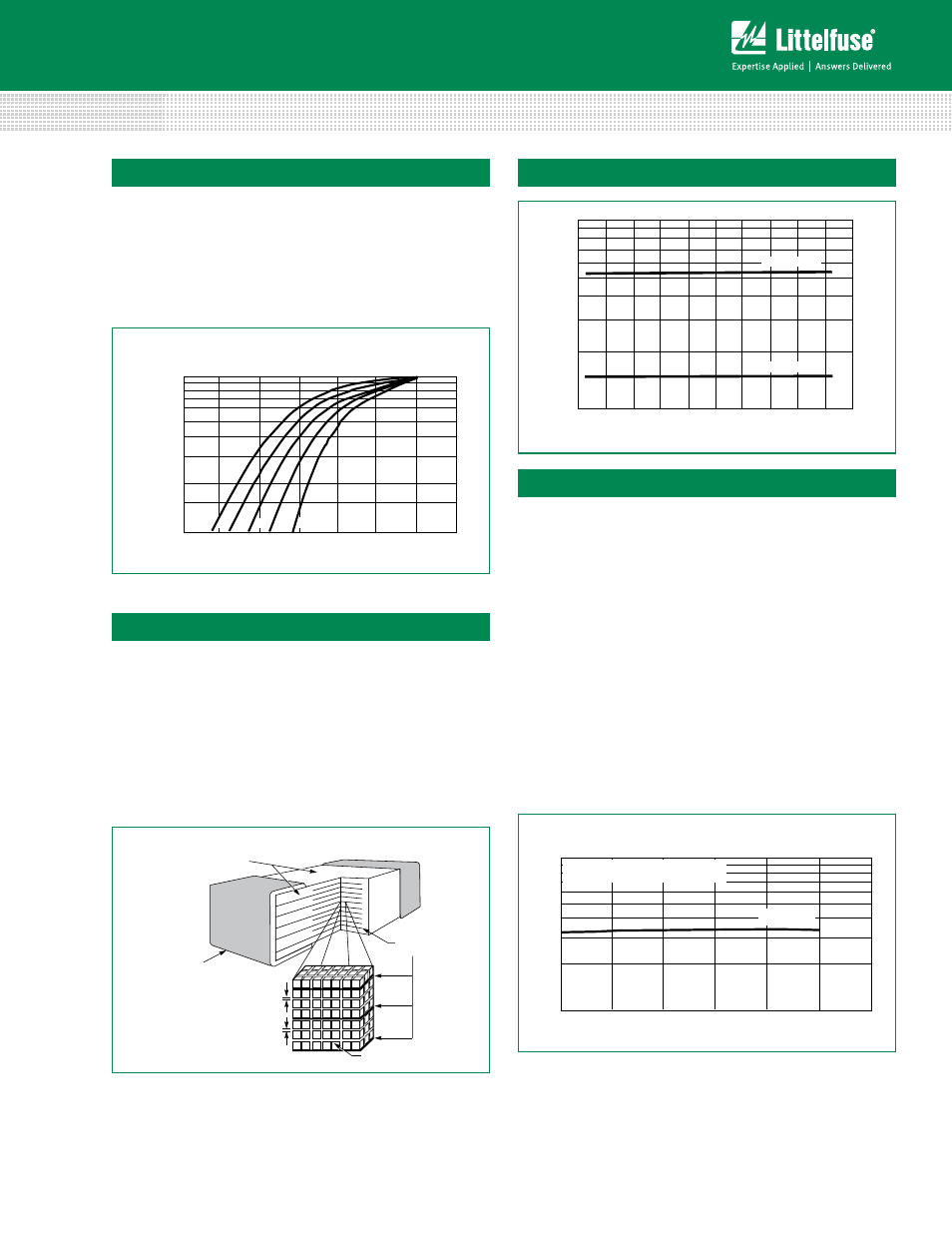

Clamping Voltage Over Temperature (V

C

at 10A)

100

10

20

V26MLA1206

40

60

80

100

120

140

TEMPERATURE (

o

C)

CLAMPING

VO

LT

AG

E

(V)

V5.5MLA1206

0

-20

-40

-60

FIGURE 12. CLAMPING VOLTAGE OVER TEMPERATURE

(V

C

AT 10A)

Typical Temperature Dependance of the Haracteristic

Curve in the Leakage Region

Speed of Response

The Multilayer Suppressor is a leadless device. Its response

time is not limited by the parasitic lead inductances found

in other surface mount packages. The response time of

the Z

N

O dielectric material is less than 1ns and the MLA

Automotive Series can clamp very fast dV/dT events such as

ESD. Additionally, in "real world" applications, the associated

circuit wiring is often the greatest factor effecting speed of

response. Therefore, transient suppressor placement within

a circuit can be considered important in certain instances.

GRAINS

DEPLETION

FIRED CERAMIC

DIELECTRIC

REGION

METAL

ELECTRODES

DEPLETION

REGION

METAL END

TERMINATION

FIGURE 11. MULTILAYER INTERNAL CONSTRUCTION

Multilayer Internal Construction

Energy Absorption/Peak Current Capability

Energy dissipated within the MLA Automotive Series is

calculated by multiplying the clamping voltage, transient

current and transient duration. An important advantage of

the multilayer is its interdigitated electrode construction

within the mass of dielectric material. This results in

excellent current distribution and the peak temperature per

energy absorbed is very low. The matrix of semiconducting

grains combine to absorb and distribute transient energy

(heat) (see Speed of Response). This dramatically reduces

peak temperature; thermal stresses and enhances device

reliability.

As a measure of the device capability in energy and peak

current handling, the V26MLA1206 part was tested with

multiple pulses at its peak current rating (150A, 8/20µs). At

the end of the test,10,000 pulses later, the device voltage

characteristics are still well within specification.

100

10

0

V26MLA1206

2000

4000

6000

8000

10000

12000

NUMBER OF PULSES

VO

LT

AG

E

FIGURE 13. REPETITIVE PULSE CAPABILITY

PEAK CURRENT = 3A

8/20 s DURATION, 30s BETWEEN PULSES

Repetitive Pulse Capability

Figure 8

Figure 9

Figure 10

Figure 11