6 q-factor calculation, 7 load supervision applications – Crown Audio IQ-PIP-USP2 User Manual

Page 18

IQ-PIP-USP2

Page 35

IQ-PIP-USP2 Reference Manual

IQ-PIP-USP2

Page 34

IQ-PIP-USP2 Reference Manual

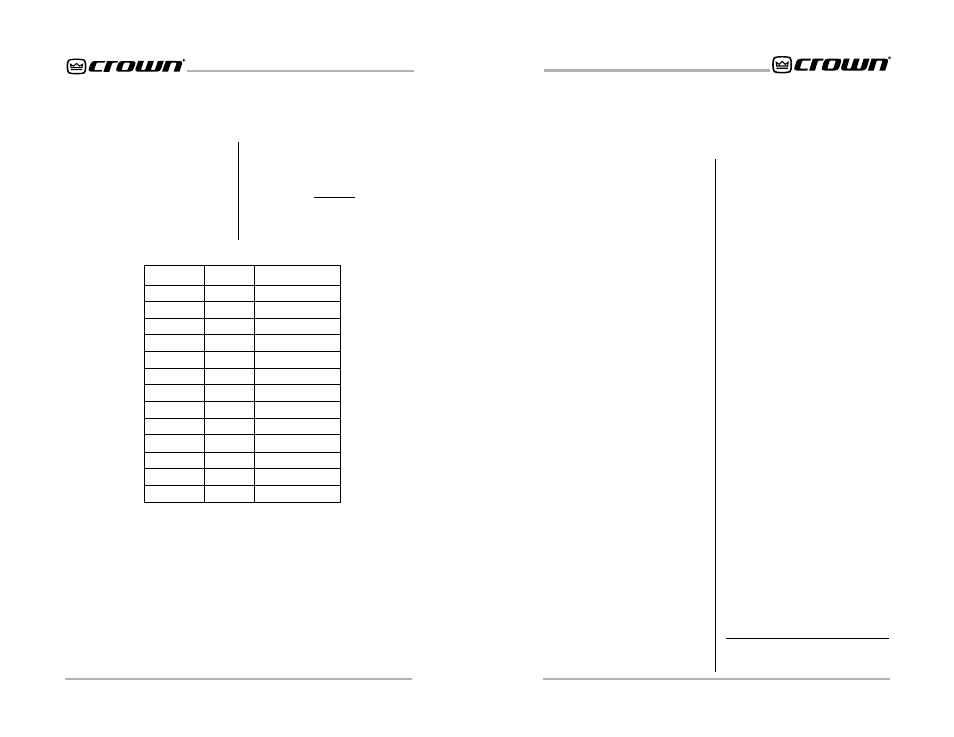

5.6 Q-Factor Calculation

Many of the DSP filters on the IQ-

PIP-USP2 feature adjustable Q-fac-

tor, which is a measure of the filter’s

selectivity or sharpness. Q-factor is

adjustable in fractions of an octave

on the IQ-PIP-USP2.

Use the table in Figure 5.9 to deter-

mine Q-factor for a given bandwidth

in octaves. The table relates the Q-

factor to bandwidth in octaves ac-

cording to the equation:

where K is the number of equal divi-

sions per octave.

Figure 5.9 Q-factor vs.Bandwidth

2

(1/2K)

1

(1/K)

–1

Q=

Q-factor

0.200

0.266

0.667

1.414

2.415

2.871

4.318

8.651

14.42

28.85

43.28

50.00

100.0

K

0.21

0.25

0.5

1

1.5

2

3

6

10

20

30

34.7

69.3

BW in Octaves

4.8

4

2

1

2/3

1/2

1/3

1/6

1/10

1/20

1/30

1/35

1/70

5.7 Load Supervision

Applications

The IQ-PIP-USP2 Load Supervision

feature can be used to monitor the

amplifier load in real time with al-

most any program material. Aver-

age load impedance is calculated

as a function of amplifier output volt-

age and current. The system re-

quires approximately 20-30 mA of

average amplifier output current for

adequate supervision. This allows

typically low average output power

levels of less than ½ watt with most

loads. The maximum load imped-

ance for reliable system perfor-

mance is limited to about 50 ohms.

Higher impedances can be mea-

sured but may require higher ampli-

fier output levels for reliable opera-

tion.

Most amplifier/load systems can be

configured and supervised by fol-

lowing these steps:

1 Configure your audio system

using a known “good” load, then

enable the Load Supervision

feature.

2 Provide typical program material

at a level high enough to light the

“test” indicator.

3 Run the system at this level until the

average impedance stabilizes.

This may take seconds to minutes

depending on level, duty-cycle,

etc.

4 Set the nominal impedance at the

measured value average. This

optimizes the supervision

algorithm for voltage and current

levels versus the actual load Note:

a higher nominal setting will

require higher output levels.

5 Set the high limit at twice average

and the low limit at one-fourth

nominal.*

6 Let the system run for extended

periods using any and all typical

program material.

7 Adjust the high/low limits, if

necessary, to account for any

variance in average measured

impedance.

8 Enable error reporting, if desired.

This procedure should work well for

most applications. However, some

applications can be a little more

difficult. Some very low-level and/or

low duty-cycle signals may not ad-

equately “test” the load. Lab and

situation testing have shown output

levels as small 40 dB below rated

amplifier output to be enough for

most low-impedance loads. Higher

impedance loads such as those used

in “lightly-loaded” 70V distribution

lines may require signal level near

20 dB below rated output.

The “Nominal Load Impedance” con-

trol is used to optimize the system

for the most accurate calculation of

load impedance. It should be set to

the expected nominal (or rated) im-

pedance of the “normal” load. The

high limit should be set for at least 2

times the expected nominal or ac-

tual measured load, while the low

limit should be set to ½ the expected

nominal or actual measured load.

* These limits are somewhat arbitrary but

should be a good starting point.