2 maintenance 2.1 maintenance table, 2 lubrication – R&M Materials Handling MANUAL CHAIN HOISTS User Manual

Page 67

RPT / RPTC INSTRUCTION MANUAL/EN/06.17.09

5/10

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

Trolley assembly procedure

1. Place the equal number of spacers of the same length on the cross shaft in between the side

plates to achieve approximately 1/8” [3 mm] of total wheel clearance between the rail and wheel

flanges.

2. Place and distribute equally the spare spacers on the exterior side of both side plates.

3. Hand-tighten the nuts to hold the trolley side plates together.

4. Gently pull the trolley downward to take up any play and even out the cross shaft holes.

5. Make sure the load point on the cross shaft is centered with the center of the rail.

6. Tighten each cross shaft nut until tight, aligning the slots in the nut with the hole in the shaft.

7.

Insert the cotter pins through each nut. Spread the cotter pin end open.

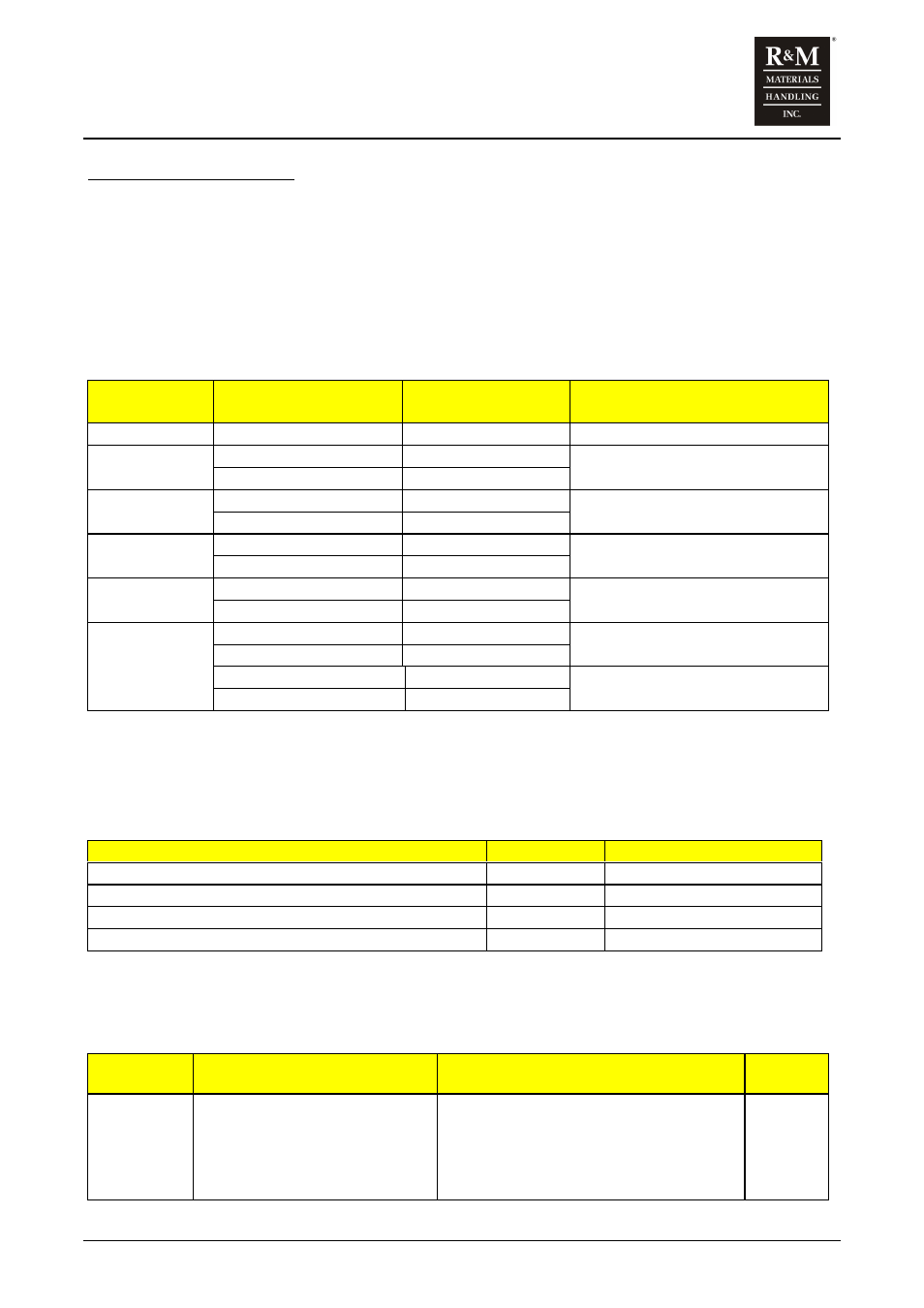

Table 1. Trolley Specifications

Models

Beam Flange Range

inch [mm]

Cross Shaft Length

inch [mm]

Maximum Capacity

lbs. [kg]

RPT-250

2 – 7.88 [50 – 200]

11 [278]

550 [250]

RPT-500

2 –7.88 [50 – 200]

12 [303]

1100 [500]

7.40 – 12.2 [188 – 310]

16.2 [411]

RPT-1000

RPTC-1000

2.56 – 7.88 [65 – 200]

12.7 [322]

2200 [1000]

7.88 – 12.2 [200 – 310]

17 [430]

RPT-2000

RPTC-2000

3.46 – 7.88 [88 – 200]

13.4 [340]

4400 [2000]

7.40 – 12.2 [188 – 310]

17.7 [448]

RPT-3000

RPTC-3000

3.93 – 7.95 [100 – 202]

14.3 [362]

6600 [3000]

7.40 – 12.20 [188 – 310]

18.5 [470]

RPT-5000

RPTC-5000

4.5 – 7.95 [114 – 202]

15.1 [384]

11000 [5000]

7.40 – 12.20 [188 – 310]

19.3 [490]

RPTC-10000

4.88 – 7.87 [124 – 200]

16.1 [408]

22000 [10000]

7.40 – 12.20 [188 – 310]

20.2 [514]

2 MAINTENANCE

2.1

Maintenance Table

Table 2. Maintenance Schedule

Check

Interval

Qualification of personnel

For loose screws and signs of corrosion

Annually

Qualified mechanic

Condition of the drive pinion

Annually

Operator

Measurement of the wheel tread diameter

Annually

Operator

Lubrication of open gear

monthly

Operator

2.2

Lubrication

Table 3. Lubrication Specifications and Brands

Lubrication

point

Specifications

Possible brands

Quantity

wheel drive

pinion

KP 0 K grease (DIN 51502)

Soap-based lithium + MoS 2

Approx. melting point + 356°F

Worked penetration 671 - 725°F

Operating temperature

Tribol: Molub Alloy multi-purpose grease

BP: Multi-purpose grease L 21 M

Mobil: Mobilgrease Special

Shell: Shell Retimax AM

Texaco: Molytex grease EP 2

As

necessary