3 setting the overload limiting device – R&M Materials Handling MANUAL CHAIN HOISTS User Manual

Page 22

RM SERIES II I&M MANUAL/EN/02.11.11

16/20

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2011) R&M Materials Handling, Inc. All rights reserved.

5.3

Setting the Overload Limiting Device

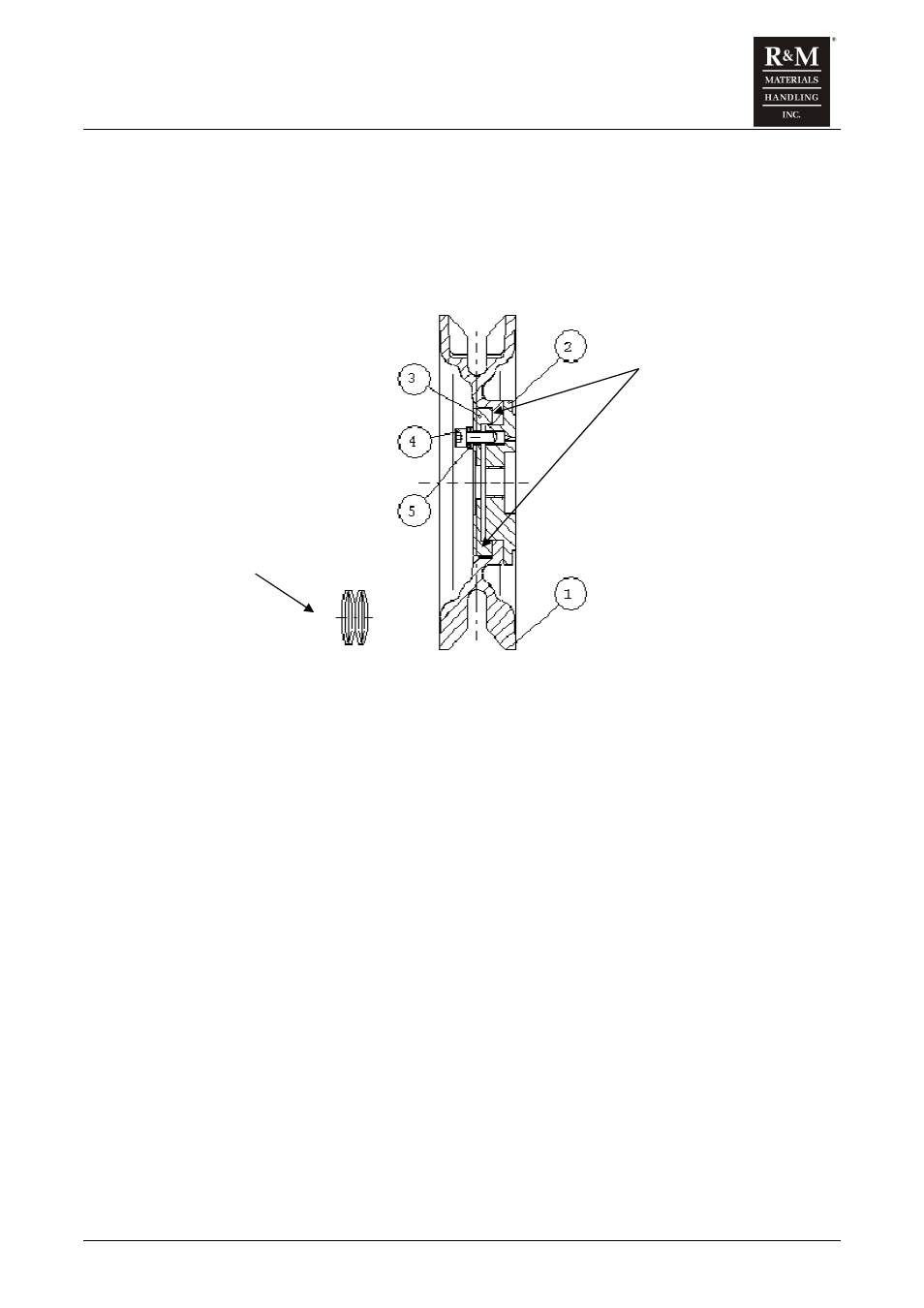

Figure 6. Cross Section of Overload Limiting Device

Setting the overload device

1. Make sure the friction surfaces are clean, free from any rust, dirt, dust, etc.

2. Lightly lubricate the friction surfaces with grease.

3. Tighten each M5 screw (4) evenly until tight.

4. Attach a test load of 1.3 times the rated capacity to the load hook.

5. Loosen each M5 screw an equal number of turns until the hand wheel slides and the test load can

no longer be lifted.

6. Test with load at capacity.

Removing the hand wheel to check the condition of the friction surfaces

1. Remove the hand chain wheel cover.

2. Remove each M5 screw (4).

3. Remove the connection plate (3).

4. Pull off the hand chain wheel (1).

5. Remove the hand chain from the hand chain wheel.

Installing the hand wheel after checking the friction surfaces

1. Place the hand chain around the wheel.

2. Insert the hand chain wheel (1).

3. Add the connection plate (3)

4. Insert each M5 screw (4) making sure the stackup of the disc springs is correct.

5. Set the overload device.

6. Reinstall the hand chain wheel cover.

1. Hand chain wheel

2. Brake disc

3. Connection plate

4. Screw M5 x 15 (3)

5. Disc spring set

Stackup of the disc

springs

Friction surfaces