1 installation, 1 trolley adjustment – R&M Materials Handling MANUAL CHAIN HOISTS User Manual

Page 66

RPT / RPTC INSTRUCTION MANUAL/EN/06.17.09

4/10

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2009) R&M Materials Handling, Inc. All rights reserved.

1 INSTALLATION

Check that:

The beam is adequate for the loads to be supported.

The beam flange dimensions correspond to the trolley to be installed.

The wheels will be able to travel freely along the rail.

All nuts are properly tightened and include the cotter pin.

The trolley wheels have adequate clearance along the entire length of rail.

The end stops are in place before operating.

1.1

Trolley Adjustment

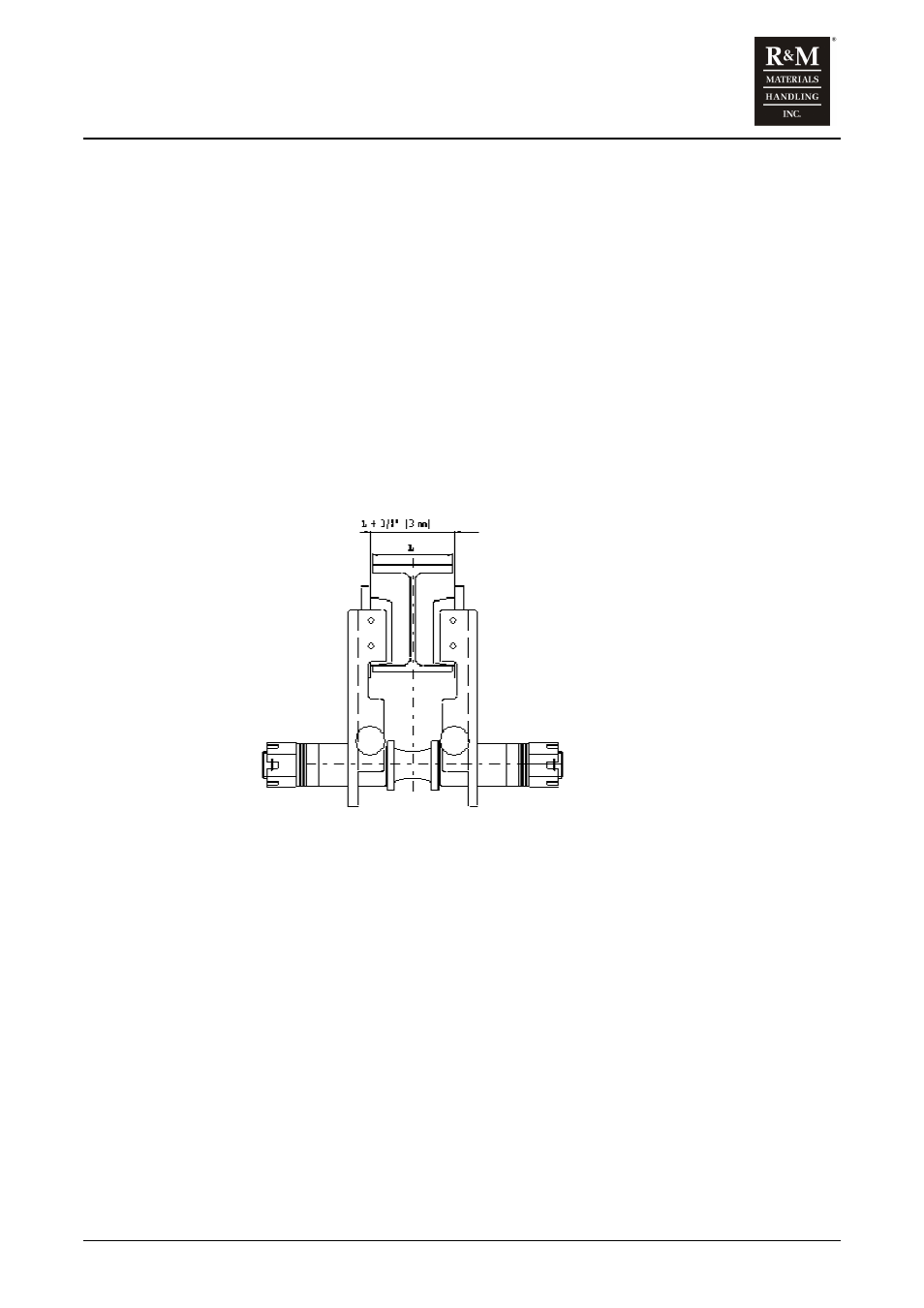

Most trolley models have two flange width ranges. In these cases, the trolley has two cross shaft lengths,

one for each range. Depending on the cross shaft supplied, the trolley is adjustable only for that individual

flange width range. The table below indicates the beam flange ranges for each trolley model.

Figure 1. Trolley Adjustment