Go with mobilero for a variety of treatment needs, General properties, Table 1: mobilero specifications – GE P&W Mobile Water Treatment Systems - MobileRO User Manual

Page 2

process. GE can provide the engineering, structure,

and operating personnel for Extended-Term appli-

cations.

Go with MobileRO for a variety of treatment

needs

•

•

•

•

•

TOC reduction for boiler feedwater use.

TDS reduction prior to demineralization.

Supplemental or emergency service to support

in-house equipment for water purification.

Post-treatment of DI water to remove bacteria,

endo-toxins and other contaminants such as

colloidal silica in ultra pure water systems.

Full scale process testing for a wide variety of

applications.

General Properties

The GE MobileRO can be readily installed in either a

pre- or post-DI position. Site requirements consist of

adequate truck/trailer parking space on a com-

pacted surface near adequate drains. The system

can produce a minimum of 200 gpm (45 m

3

/hr) at

40°F (4.4°C) with a 300 gpm (67.5 m

3

/hr) feedwater

supply at 50 psig (3 bar) minimum pressure. Rejec-

tion rates of 90% to 99+% can be obtained, at

recovery rates of 65% to 85%, depending on influ-

ent TDS and ionic composition. See Table 1 for

MobileRO specifications.

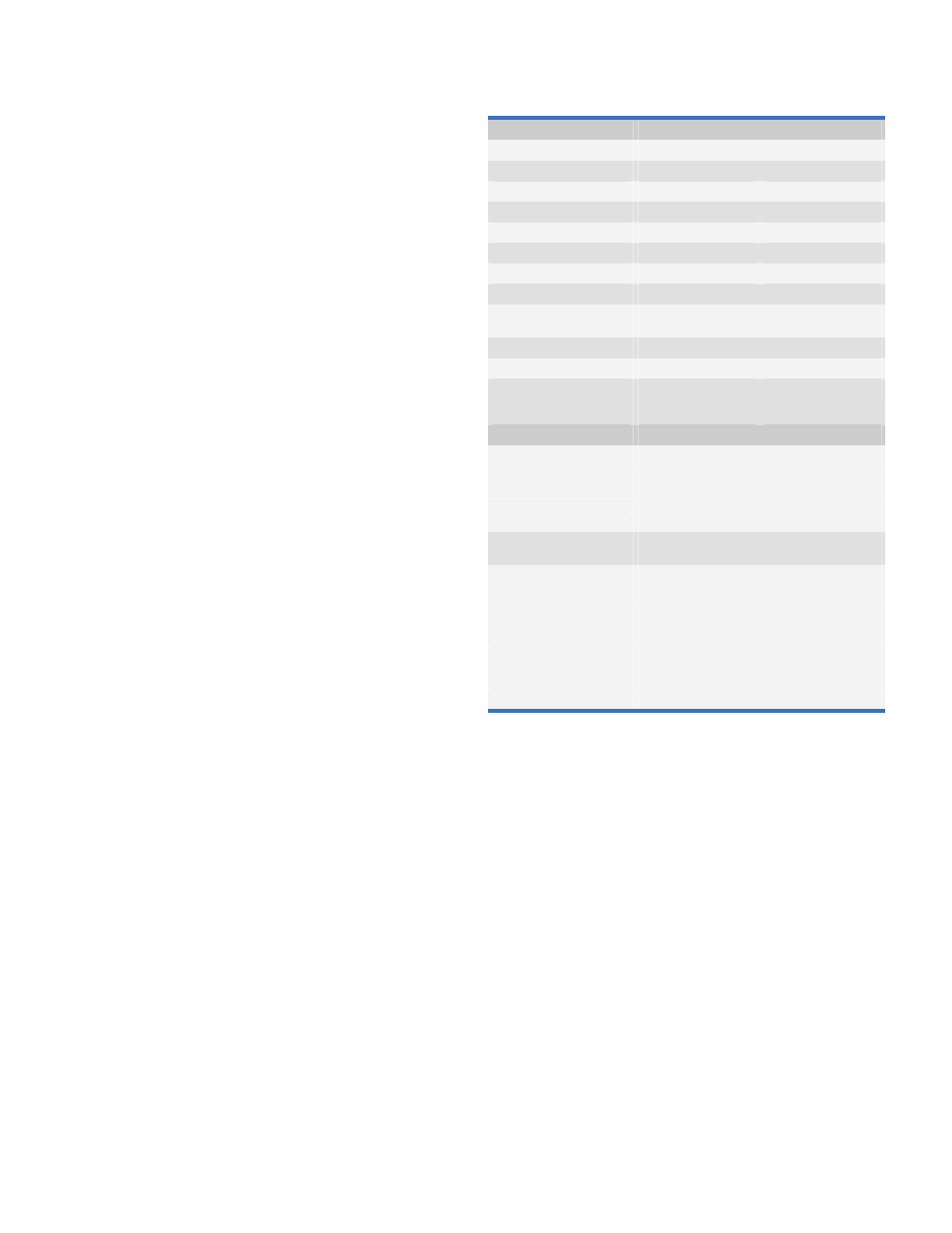

Table 1: MobileRO Specifications

TRAILER

Dimensions and weights

U.S. Version

International Version

Overall length with tractor

60’-0”

16.5 m

Trailer length

48’-0”

13.2 m

Trailer height

13’-6”

4 m

Trailer width

8’-0”

2.6 m

Gross trailer operating weight

41,400 lbs.

18,800 kg

Lighting and instrumentation

110V, 20 amps

220/240V, 20 amps

RO

480V, 200 amps

380-415V, 200 amps

Connections

All connections are located on underside of trailer,

mid-trailer, curbside.

Inlet/outlet

4” flange

4” flange

RO Reject

2” flange

2” flange

Heating

25,000 BTU/H propane

fired heater and propane

supply tank.

Electric heater, 3 KW

RO SYSTEM - ON BOARD

Specifications

• Two pre- or post-treatment ASME code vessels.

• 200 GPM (45 m3/hr) @ 40° F (4.4°C) Reverse

Osmosis System.

• Two x 100 GPM (23 m3/hr) arrays with stainless

steel housings.

Membranes

• Spiral wound cellulose acetate or polyamide thin

film composite

Instrumentation

• Flow indicator and totalizer

• System pressure gauges

• Conductivity or resistivity meter

• Feed pressure control system

• pH controller

• Acid, chlorine & inhibitor feed systems

• 5 micron cartridge prefilter

Page 2

FS1058EN 0607