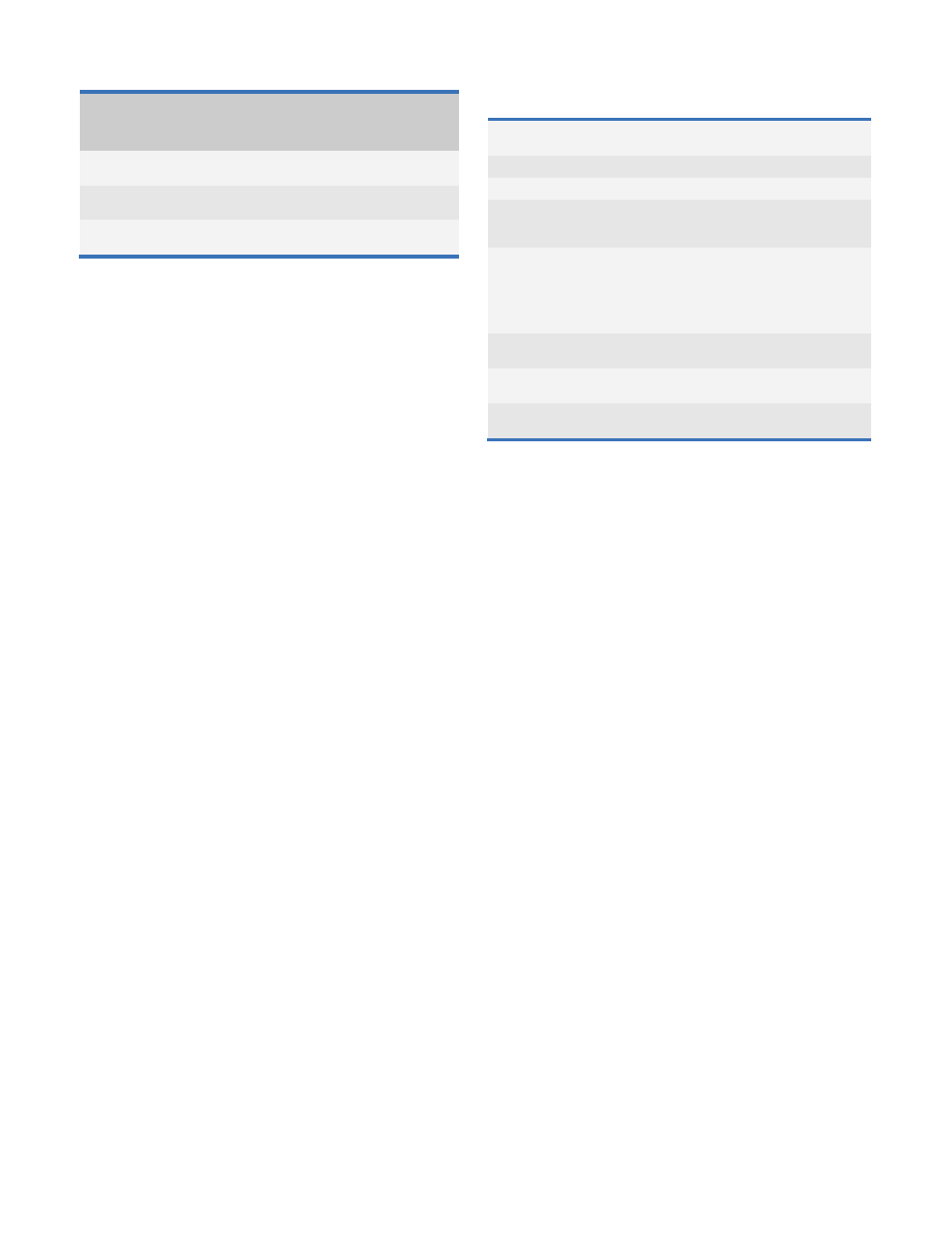

Table 3: operating and cip parameters – GE P&W Spiral Wound Membranes - Duraslick Series User Manual

Page 2

Page 2

FS1269EN

Model

1

Dimensions, inches (cm)

Boxed

A

B

2

C

3

Weight

lbs (kg)

Duraslick XX2540

40.0

(101.6)

0.75

(1.9) OD

2.4

(6.1)

4

(1.8)

Duraslick XX4040

40.0

(101.6)

0.75

(1.9) OD

3.9

(9.9)

9

(4.1)

Duraslick XX8040

40.0

(101.6)

1.125

(2.86)

7.9

(20.0)

29

(13.2)

1

These elements are dried and bagged before shipping.

2

Internal diameter.

3

The element diameter (dimension C) is designed for optimum performance in GE

pressure vessels. Others pressure vessel dimension and tolerance may result in

excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

Typical Operating Pressure

Duraslick RO: 200psi (1,379 kPa)

Duraslick NF: 100psi (690 kPa)

Typical Operating Flux

10-15GFD (15-25LMH)

Maximum Operating Pressure

600psi (4,137 kPa)

Maximum Temperature

Continuous Operation: 122°F (50°C)

Duraslick RO Clean-In-Place: 122°F (50°C)

Duraslick NF Clean-In-Place: 104°F (40°C)

pH Range

Duraslick RO:

Continuous Operation: 4.0 – 10.0

Clean-In-Place (CIP): 2.0 – 10.5

Duraslick NF:

Continuous Operation: 3.0 – 9.0

Clean-In-Place (CIP): 2.0 – 10.5

Maximum Pressure Drop

Over an element: 12psi (83 kPa)

Per housing: 50psi (345 kPa)

Chlorine Tolerance

500 ppm-hrs,

dechlorination recommended

Feedwater

NTU < 1

SDI < 5