GE P&W Spiral Wound Membranes - Duraslick Series User Manual

Duraslick* series, Low fouling nf/ro elements, Fact sheet

Find a contact near you by visiting www.gewater.com and clicking on “Contact Us”.

* Trademark of General Electric Company; may be registered in one or more countries.

©2013, General Electric Company. All rights reserved.

FS1269EN.doc Nov-13

Fact Sheet

Duraslick* Series

Low Fouling NF/RO Elements

Duraslick

*

is a family series of membrane elements

engineered for use with fouling-prone brackish wa-

ter applications and industrial effluent treatment

before reuse or discharge. Duraslick* is designed to

utilize an innovative three-layer membrane, of

which a proprietary middle layer creates extreme

smoothness, and provide a high rejection of salts.

Independent studies have demonstrated that Du-

raslick* elements are superior to standard polyam-

ide spiral wound membrane elements for salt

removal in fouling environment. Duraslick* ele-

ments retrofit existing systems to obtain stable

permeate flux, reduced overall energy usage, in-

creased membrane service life and an extension of

operating time between required cleanings, which

in turn reduces expenditures on required chemicals.

Table 1: Element Specification

Membrane

Thin-film membrane (TFM*)

Model

Average

permeate flow

gpd (m3/day)

1,2

Average NaCl

rejection

1,2

Minimum NaCl

rejection

1,2

Duraslick RO2540

550 (2.1)

98.6%

97.0%

Duraslick RO4040

1,900 (7.2)

98.6%

97.0%

Duraslick RO8040

7,700 (29.1)

98.6%

97.0%

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-25%.

2

Testing conditions: 800ppm NaCl solution at 225psig (1,551 kPa) operating

pressure, 77°F (25°C), pH7.5 and 15% recovery.

Model

Average

permeate flow

gpd (m3/day)

1,2

Average

MgSO4

rejection

1,2

Minimum

MgSO4

rejection

1,2

Duraslick NF2540

600 (2.3)

98.6%

96.0%

Duraslick NF4040

2,400 (9.1)

98.6%

96.0%

Duraslick NF8040

8,600 (32.6)

98.6%

96.0%

1

Average salt rejection after 24 hours operation. Individual flow rate may vary

+25%/-25%.

2

Testing conditions: 2,000ppm MgSO

4

solution at 110psi (760kPa) operating

pressure, 77°F (25°C), pH7.5 and 15% recovery.

Model

Spacer

mil (mm)

Active area

ft

2

(m

2

)

Outer wrap

Part

number

Duraslick RO2540

30 (0.76)

24 (2.2)

Fiberglass

1231055

Duraslick RO4040

30 (0.76)

80 (7.4)

Fiberglass

1231048

Duraslick RO8040

30 (0.76)

355 (33.0)

Fiberglass

1231014

Duraslick NF2540

30 (0.76)

24 (2.2)

Fiberglass

1234385

Duraslick NF4040

30 (0.76)

80 (7.4)

Fiberglass

1234307

Duraslick NF8040

30 (0.76)

355 (33.0)

Fiberglass

1234182

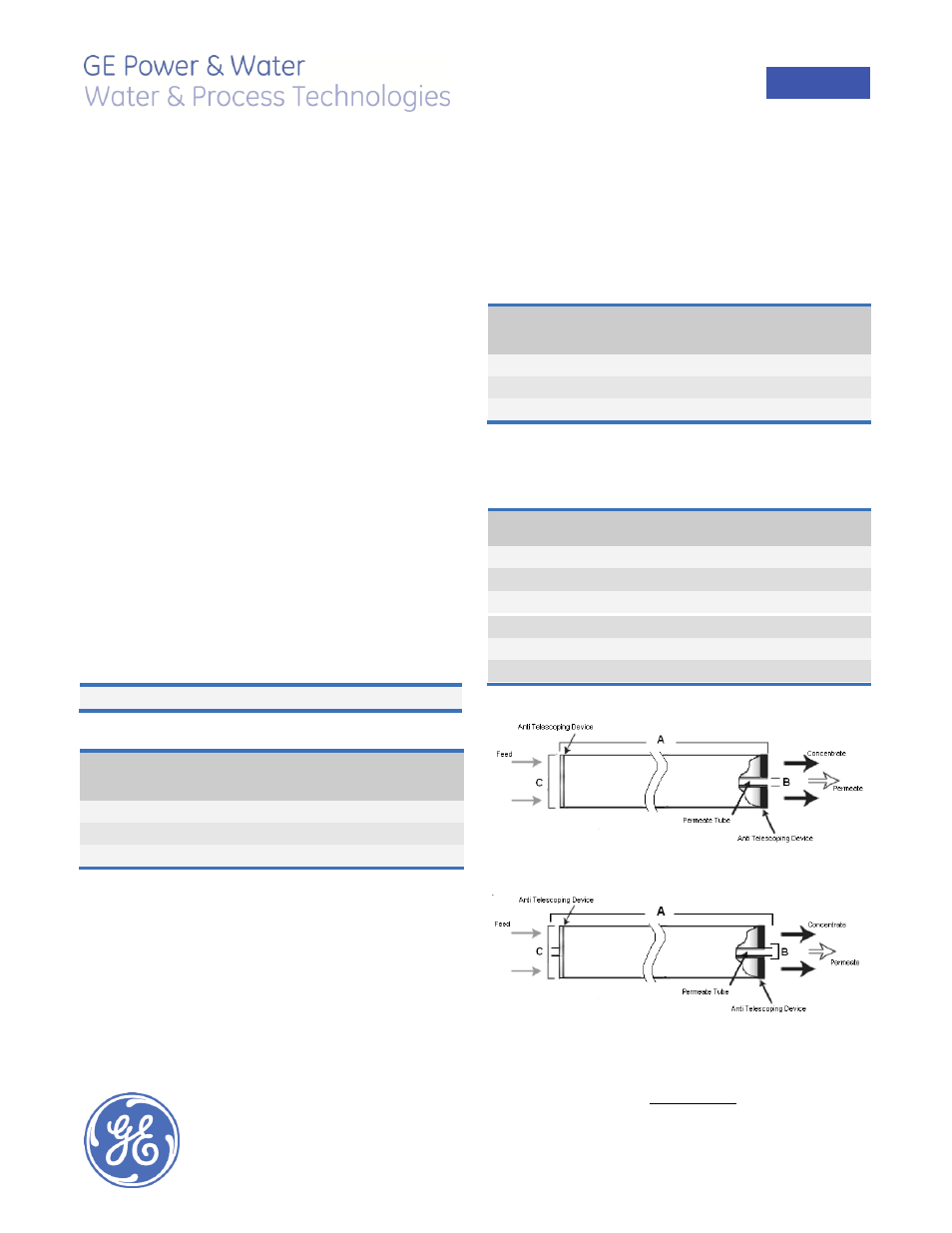

Figure 1: Element Dimensions Diagram – 8040

Figure 2: Element Dimensions Diagram – 2540 & 4040

Table 2: Dimensions and Weight