Hot water sanitization recommendations, Salt rejection – GE P&W Spiral Wound Membranes - Duratherm HWS Series User Manual

Page 3

Hot Water Sanitization

Recommendations

For optimal performance, Duratherm HWS ele-

ments should always be cleaned using approved

CIP procedures and flushed with fouling free wa-

ter before the sanitization process. Feed pressure

during sanitization should not exceed 40psi

(275kPa) and the crossflow should not incur a

pressure drop greater than 2psi (14kPa) per ele-

ment. Heating rate to sanitizing temperature and

cool down should not be faster than 5°C

(41°F)/minute. Maximum sanitization temperature

is 90°C (194°F).

Loss of permeate flow after repeated

90°C (194°F) sanitization cycles

It is almost impossible to exactly predict the per-

centage of permeate flow rate lost from the high

temperature sanitations, which among other fac-

tors depends on:

1) Rate of temperature increase and decrease.

2) Presence of other species like organics, ionic

and metallic compounds that could locally de-

crease or increase the temperature at the sur-

face of the membrane.

3) Feed flow rate and specifically the heat trans-

fer rate to the membrane surface.

4) The thickness and geometry of the feed spac-

er used.

At optimum conditions measured in controlled

environment with deionized water, between 30%

and 50% of the original permeate flow rate was

lost before the element performance had stabi-

lized after repeated heat treatments (over 90% of

this flow reduction occurred during the first heat

treatment). With the loss of permeate flow rate,

the salt rejection increases. The rate of cooling

and heating was not more than 5°C (41°F) per mi-

nute, and the differential pressure drop per ele-

ment did not exceed 2 psi.

Pilot testing based on the criteria noted above will

give the best operating parameters for any specif-

ic application.

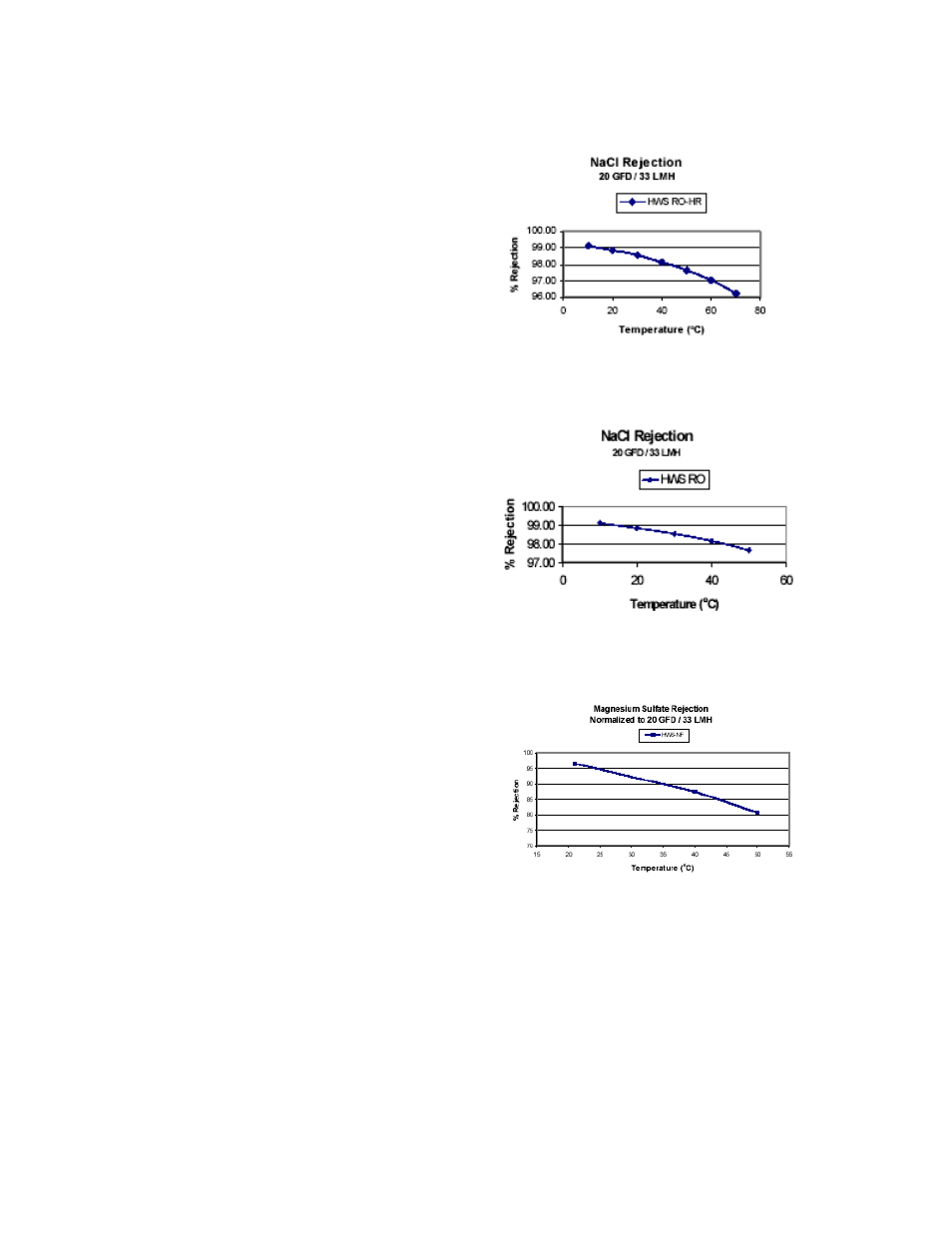

Salt Rejection

Figure 2: NaCl rejection for HWS RO HR element

Figure 3: NaCl rejection for HWS RO element

Figure 4: MgSO4 rejection for HWS NF HF element

FS1270EN

Page 3