Additional information – GE P&W Pleated Filters - Memtrex PM Pleated Filters User Manual

Page 2

Page 2

FS1084EN 0702

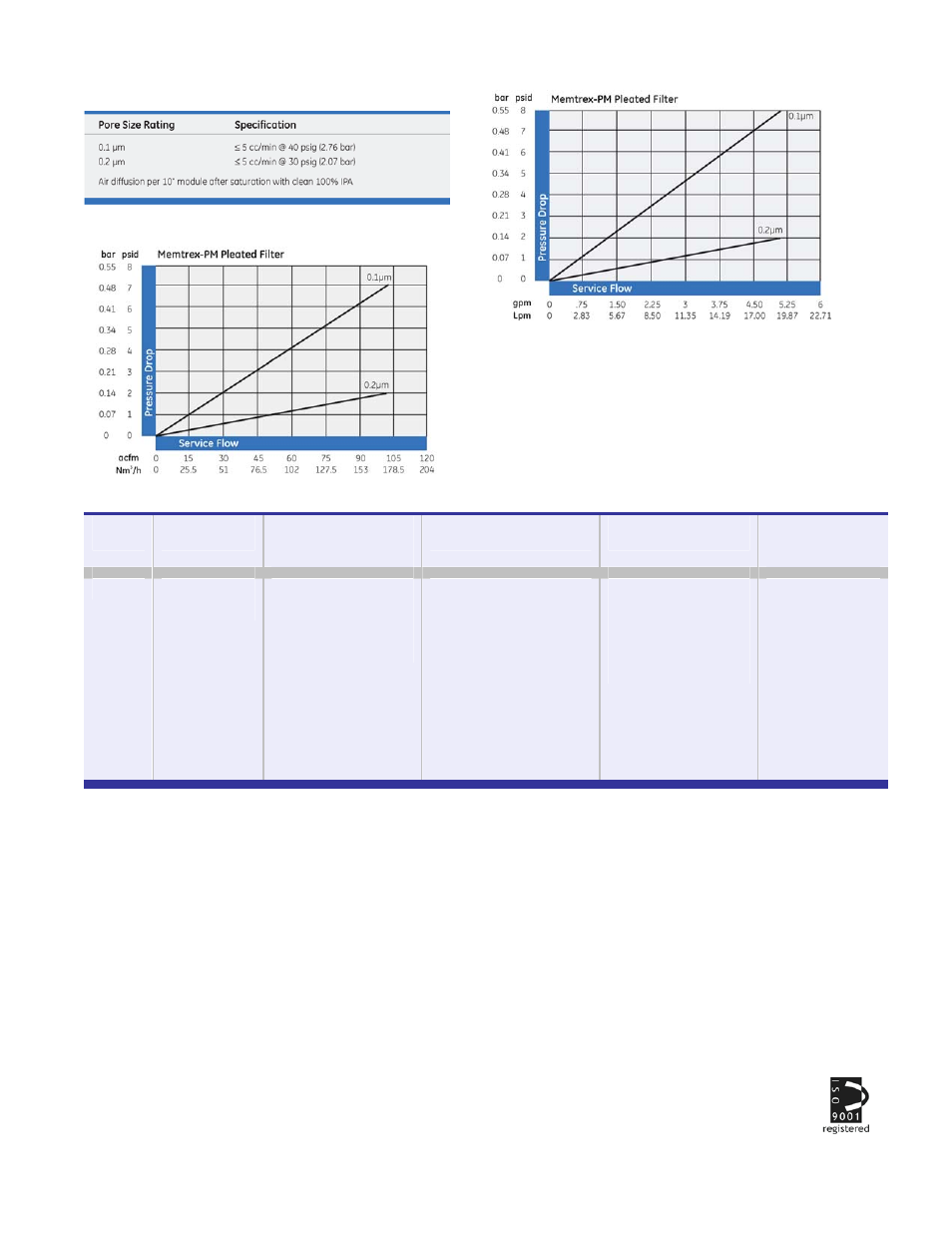

Table 4: Integrity Testing

Table 5: Flow Performance in Clean Air

1

Table 6: Flow Performance in Clean Water

1

1

Data based on 10” length filter

Table 7: Ordering Information

Type

Micron Rating

Nominal Cartridge

Length

End #1 Adapter

End #2 Adapter

Elastomer Mate-

rial

MPM

91 = 0.1 µm

92 = 0.2 µm

1 = 10 in. (25.4 cm)

2 = 20 in. (50.8 cm)

3 = 30 in. (76 cm)

4 = 40 in. (101.5 cm)

A =

Open End Gasket

B =

120 O-Ring

C =

213 O-Ring

E =

222 O-Ring

F =

226 O-Ring

J =

020 O-Ring

Q =

222 O-Ring

Stainless Steel Insert

Z =

226 O-Ring

Stainless Steel Insert

A =

Open End Gasket

B =

120 O-Ring

C =

213 O-Ring

G =

Closed End Cap

H = Fin Adapter

B = Buna-N

E = EPDM

S = Silicone

T = Teflon

2

Encapsulated

(Only in 222

and 226

Sizes

V = Viton

2

2

Teflon and Viton are registered trademarks of Dupont

Additional Information

• Memtrex PM filters may be autoclaved or in situ

steam sterilized (up to 253°F [123°C], 30 minute

cycles) for a maximum accumulated exposure

of 10 hours. Alternatively, the filters may be

sanitized with compatible chemical agents.

• GE certifies that the materials contained in its

Memtrex PM pleated filters meet U.S. FDA

requirements for food contact under the appli-

cable regulations in 21 CFR. For further informa-

tion, contact the GE technical services. Memtrex

PM filters meet the test criteria for USP class VI-

121°C Plastics.

• Aqueous extracts from Memtrex PM filters con-

tain less than 0.25 EU/ml. The filters typically

exhibit low levels of non-volatile residues. GE fil-

ter cartridges are designed and manufactured

for resistance to a wide range of chemical solu-

tions. Conditions will vary with each application

and users should carefully verify chemical com-

patibility. Please contact your GE distributor for

more information.

• Table 7 provides more information on ordering

Memtrex PM filters.