Detailed description – Rainbow Electronics MAX1717 User Manual

Page 14

MAX1717

Dynamically Adjustable, Synchronous

Step-Down Controller for Notebook CPUs

14

______________________________________________________________________________________

Detailed Description

+5V Bias Supply (V

CC

and V

DD

)

The MAX1717 requires an external +5V bias supply in

addition to the battery. Typically, this +5V bias supply

is the notebook’s 95% efficient +5V system supply.

Keeping the bias supply external to the IC improves

efficiency and eliminates the cost associated with the

+5V linear regulator that would otherwise be needed to

supply the PWM circuit and gate drivers. If stand-alone

capability is needed, the +5V supply can be generated

with an external linear regulator.

The +5V bias supply must provide V

CC

(PWM con-

troller) and V

DD

(gate-drive power), so the maximum

current drawn is:

I

BIAS

= I

CC

+ f (Q

G1

+ Q

G2

) = 10mA to 40mA (typ)

where I

CC

is 700µA (typ), f is the switching frequency,

and Q

G1

and Q

G2

are the MOSFET data sheet total

gate-charge specification limits at V

GS

= 5V.

V+ and V

DD

can be tied together if the input power

source is a fixed +4.5V to +5.5V supply. If the +5V bias

supply is powered up prior to the battery supply, the

enable signal (SKP/SDN going from low to high or

open) must be delayed until the battery voltage is pre-

sent to ensure startup.

Free-Running, Constant On-Time PWM

Controller with Input Feed-Forward

The Quick-PWM control architecture is a pseudofixed-

frequency, constant-on-time current-mode type with volt-

age feed-forward (Figure 2). This architecture relies on

the output filter capacitor’s ESR to act as the current-

sense resistor, so the output ripple voltage provides the

PWM ramp signal. The control algorithm is simple: the

high-side switch on-time is determined solely by a one-

shot whose period is inversely proportional to input volt-

age and directly proportional to output voltage. Another

one-shot sets a minimum off-time (400ns typ). The on-

time one-shot is triggered if the error comparator is low,

the low-side switch current is below the current-limit

threshold, and the minimum off-time one-shot has timed

out.

On-Time One-Shot (TON)

The heart of the PWM core is the one-shot that sets the

high-side switch on-time. This fast, low-jitter, adjustable

one-shot includes circuitry that varies the on-time in

response to battery and output voltage. The high-side

switch on-time is inversely proportional to the battery

voltage as measured by the V+ input, and proportional

to the output voltage. This algorithm results in a nearly

constant switching frequency despite the lack of a

fixed-frequency clock generator. The benefits of a con-

stant switching frequency are twofold: first, the frequency

can be selected to avoid noise-sensitive regions such

as the 455kHz IF band; second, the inductor ripple-cur-

rent operating point remains relatively constant, resulting

in easy design methodology and predictable output

voltage ripple.

On-Time = K (V

OUT

+ 0.075V) / V

IN

where K is set by the TON pin-strap connection and

0.075V is an approximation to accommodate the expect-

ed drop across the low-side MOSFET switch (Table 3).

The on-time one-shot has good accuracy at the operating

points specified in the Electrical Characteristics (±10% at

200kHz and 300kHz, ±12% at 550kHz and 1000kHz).

On-times at operating points far removed from the condi-

tions specified in the Electrical Characteristics can vary

over a wide range. For example, the 1000kHz setting will

typically run about 10% slower with inputs much greater

than +5V due to the very short on-times required.

On-times translate only roughly to switching frequencies.

The on-times guaranteed in the Electrical Character-

istics are influenced by switching delays in the external

high-side MOSFET. Resistive losses, including the

inductor, both MOSFETs, output capacitor ESR, and PC

board copper losses in the output and ground tend to

raise the switching frequency at higher output currents.

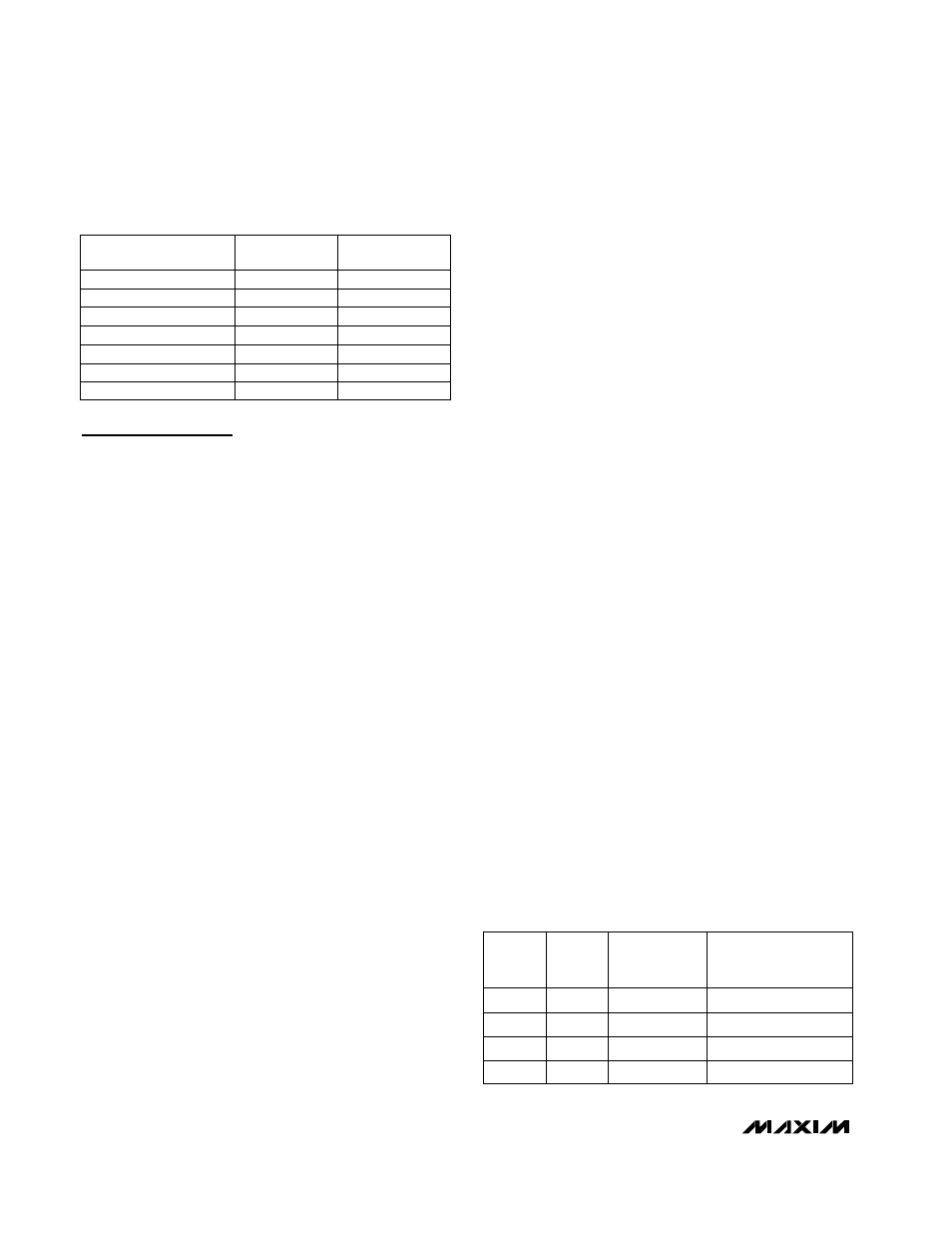

Table 2. Component Suppliers

Table 3. Approximate K-Factors Errors

±10

TON

SETTING

(kHz)

APPROXIMATE

K-FACTOR

ERROR (%)

MIN RECOMMENDED

V

BATT

AT V

OUT

= 1.6V

(V)

200

±10

2.1

300

2.3

550

±12.5

3.2

1000

±12.5

4.5

K

FACTOR

(µs)

5

3.3

1.8

1.0

MANUFACTURER

USA PHONE

FACTORY FAX

[Country Code]

Coilcraft

847-639-6400

[1] 847-639-1469

Dale-Vishay

402-564-3131

[1] 402-563-6418

[1] 310-322-3332

310-322-3331

International Rectifier

Kemet

408-986-0424

[1] 408-986-1442

[1] 714-373-7183

714-373-7939

Panasonic

[81] 3-3607-5144

847-956-0666

408-573-4150

[1] 408-573-4159

Sumida

Taiyo Yuden