Rainbow Electronics MAX17000 User Manual

Page 24

MAX17000

Complete DDR2 and DDR3 Memory

Power-Management Solution

24

______________________________________________________________________________________

stresses and thus drives the selection of input

capacitors, MOSFETs, and other critical heat-con-

tributing components. Most notebook loads gener-

ally exhibit I

LOAD

= I

LOAD(MAX)

x 80%.

•

Switching Frequency: This choice determines the

basic trade-off between size and efficiency. The

optimal frequency is largely a function of maximum

input voltage, due to MOSFET switching losses that

are proportional to frequency and V

IN

2

. The opti-

mum frequency is also a moving target, due to

rapid improvements in MOSFET technology that are

making higher frequencies more practical.

•

Inductor Operating Point: This choice provides

trade-offs between size vs. efficiency and transient

response vs. output noise. Low inductor values pro-

vide better transient response and smaller physical

size, but also result in lower efficiency and higher

output noise due to increased ripple current. The

minimum practical inductor value is one that causes

the circuit to operate at the edge of critical conduc-

tion (where the inductor current just touches zero

with every cycle at maximum load). Inductor values

lower than this grant no further size-reduction bene-

fit. The optimum operating point is usually found

between 20% and 50% ripple current.

Inductor Selection

The switching frequency and operating point (% ripple

current or LIR) determine the inductor value as follows:

Find a low-loss inductor having the lowest possible DC

resistance that fits in the allotted dimensions. Ferrite

cores are often the best choice, although powdered

iron is inexpensive and can work well at 200kHz. The

core must be large enough not to saturate at the peak

inductor current (I

PEAK

):

Setting the Valley Current Limit

The minimum current-limit threshold must be high

enough to support the maximum load current when the

current limit is at the minimum tolerance value. The val-

ley of the inductor current occurs at I

LOAD(MAX)

minus

half the ripple current; therefore:

where I

LIMIT(LOW)

equals the minimum current-limit

threshold voltage divided by the output sense element

(inductor DCR or sense resistor).

The valley current limit is fixed at 17mV (min) across the

CSH to CSL differential input.

Special attention must be made to the tolerance and

thermal variation of the on-resistance in the case of DCR

sensing. Use the worst-case maximum value for R

DCR

from the inductor data sheet, and add some margin for

the rise in R

DCR

with temperature. A good general rule

is to allow 0.5% additional resistance for each °C of

temperature rise, which must be included in the design

margin unless the design includes an NTC thermistor in

the DCR network to thermally compensate the current-

limit threshold.

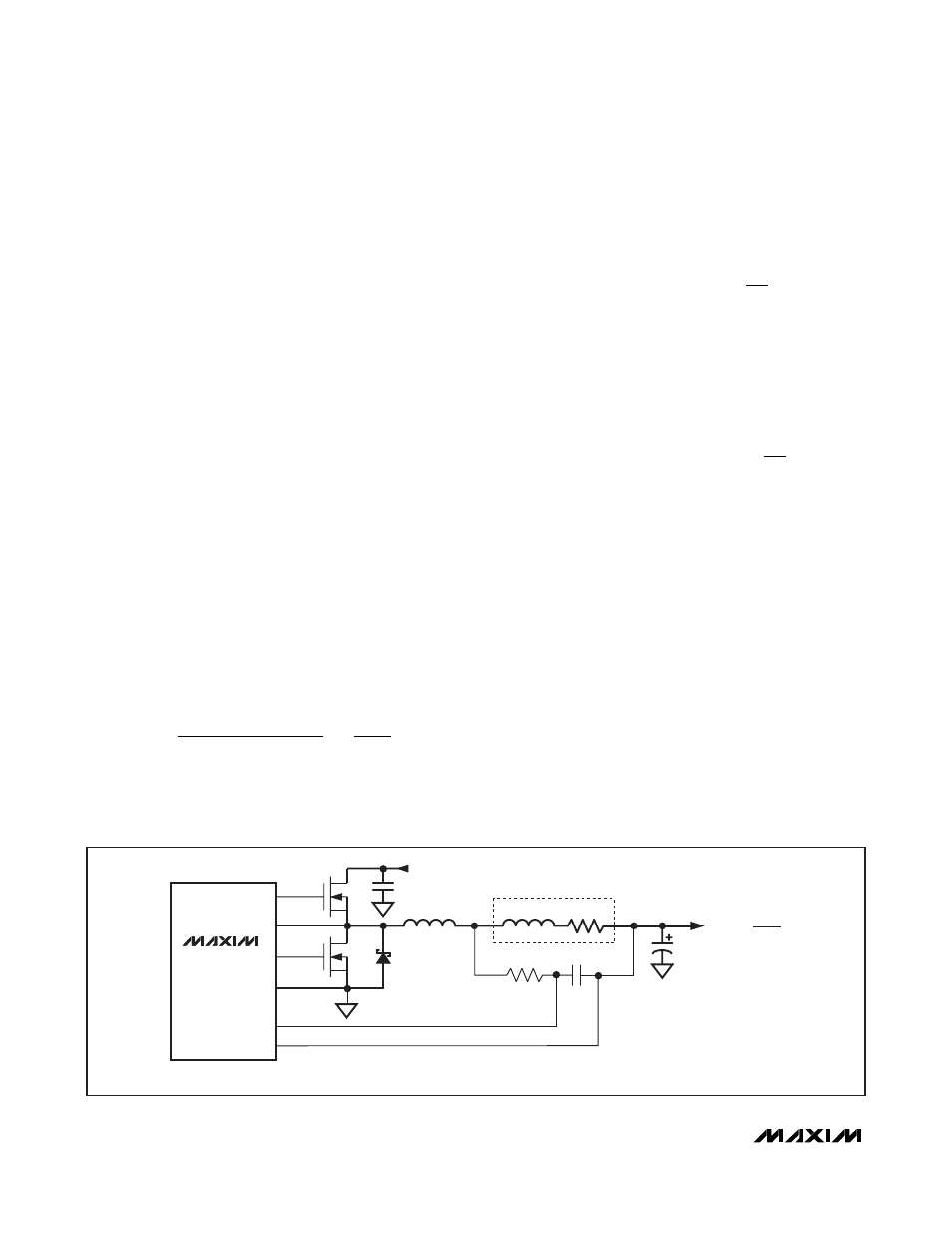

The current-sense method (Figure 7) and magnitude

determine the achievable current-limit accuracy and

power loss. The sense resistor can be determined by:

R

SENSE

= V

LIMIT

/I

LIMIT

I

I

LIR

LIMIT LOW

LOAD MAX

(

)

(

)

>

× −

⎛

⎝⎜

⎞

⎠⎟

1

2

I

I

LIR

PEAK

LOAD MAX

=

× +

⎛

⎝⎜

⎞

⎠⎟

(

)

1

2

L

V

V

f

I

LIR

V

V

IN

OUT

SW

LOAD MAX

OUT

IN

=

−

Ч

Ч

⎛

⎝

⎜

⎞

⎠

⎟ Ч

⎛

(

)

⎝⎝⎜

⎞

⎠⎟

SENSE RESISTOR

L

MAX17000

C

OUT

INPUT (V

IN

)

C

IN

CSL

CSH

PGND1

DL

DH

LX

C

EQ

R

EQ

N

H

N

L

D

L

L

ESL

R

SENSE

C

EQ

R

EQ

=

L

ESL

R

SENSE

A) OUTPUT SERIES RESISTOR SENSING

Figure 7a. Current-Sense Configurations (Sheet 1 of 2)