Caulking sidewall sheet seams – Grain Systems Tanks PNEG-1093 User Manual

Page 30

6. Installation

30

PNEG-1093 2.66" Corrugation Unstiffened Bin

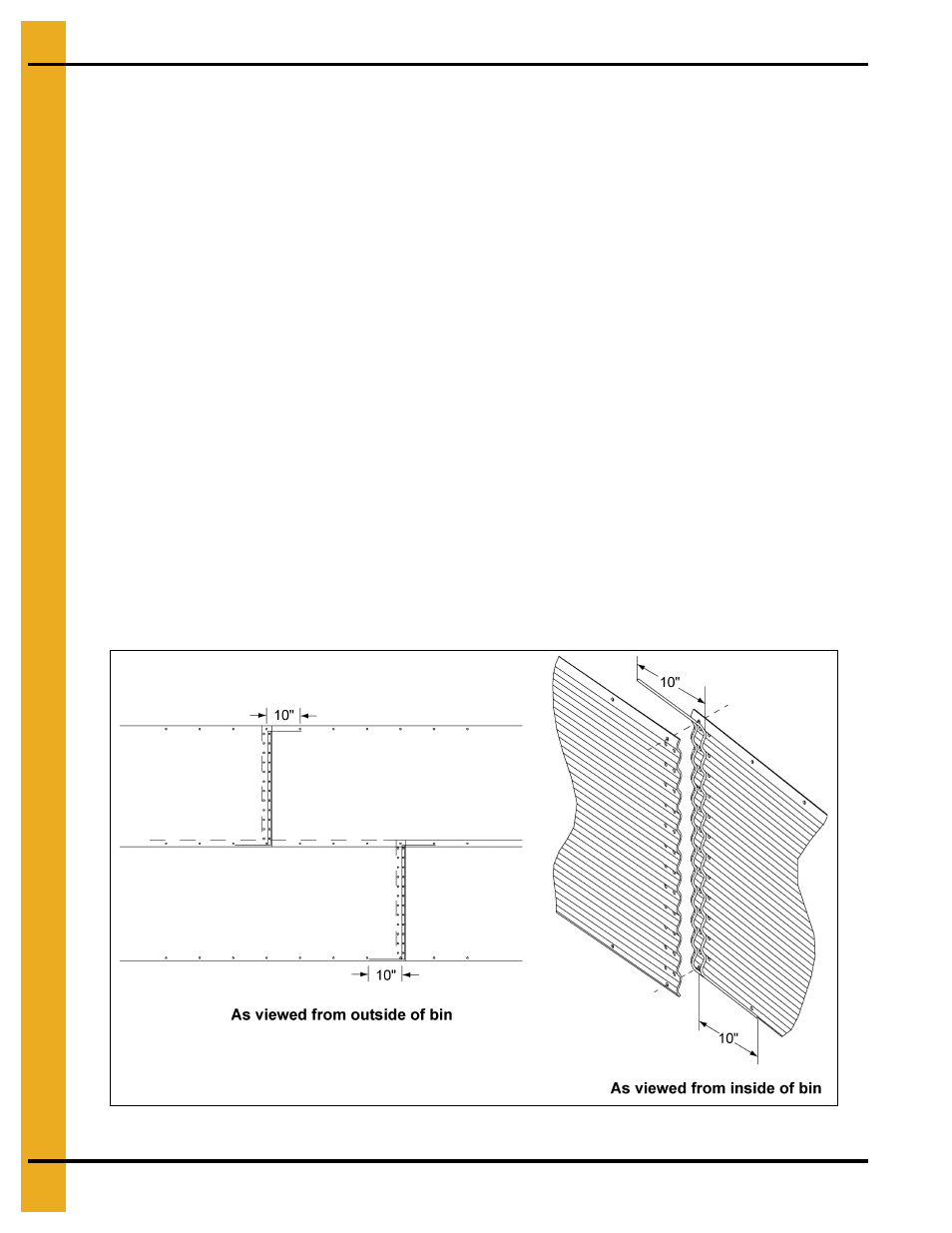

Caulking Sidewall Sheet Seams

1. Apply one strip of caulking near the outside edge of the outer sheet and between the two (2) rows

of bolts, refer to

below. A strip of caulking 10" long, should be placed along the

horizontal seams.

2. Before bolting the next ring in place, apply one strip of caulking 10" long on the front of the

underlapped sheet at each joint.

3. Also, a 10" strip of caulking is to be placed along lower horizontal edge of lapping sheet at every

vertical seam lap. This will fill the space that occurs between the holes caused by the overlapped

sheets. Additional 10" strips must be used to fill larger gaps that occur with heavier gauges and

laminated gauges.

4. Using correct size bin bolts throughout, begin assembling sidewall sheets end to end (overlapping

the same way throughout) until the ring is completed. All body sheet bolts are to be installed with the

bolt head and its neoprene washer to the outside and the nut on the inside. Do not tighten bolts

until all sheets are assembled and form a complete ring.

5. Remember to attach lifting straps at the bottom of the vertical seams while bolting the sheets

together. These straps, coupled to the jacks will enable you to later elevate the bin.

6. Now tighten the bolts in sequence, starting from the center and working to the edge in both directions.

This permits the sidewall sheets to draw-up evenly. Complete one ring and stop.

7. You are now ready to assemble the roof. Refer to roof erection manual for roof assembly instructions

located in roof hardware box.

NOTE: The rope caulking is installed before each sheet is assembled. There is sufficient caulking for all

vertical seams on storage and drying bins. Wipe sheet clean where caulking is to be applied.

Figure 6D Caulking Detail