Serviceability, Easy to maintain – easy to service – Milton CAT 966H User Manual

Page 16

•

Grouped service points and sight

gauges for easy daily maintenance

•

Convenient access to engine

compartment for excellent

serviceability

•

Swing-out grill and cooling cores for

easy cleaning

•

Electronic systems to monitor

product health

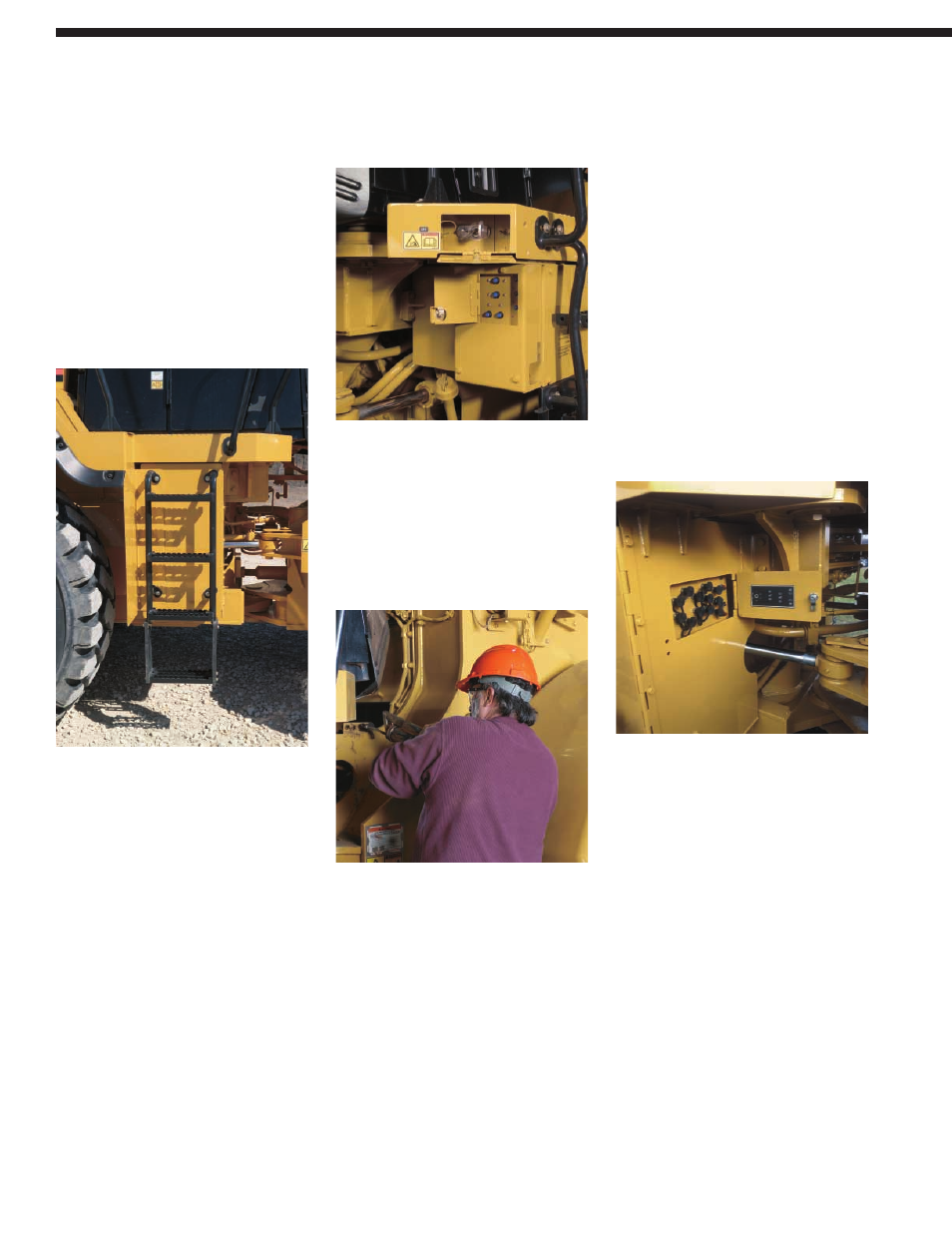

HYDRAULIC SERVICE CENTER.

Transmission oil and hydraulic filters are

located in the Hydraulic Service Center,

behind the hinged, right-side access

ladder. The hydraulic oil tank can be

drained from this location using the

access port.

•

Hydraulic filter change interval at

500 hours

•

Transmission filter change interval

at 1,000 hours

ELECTRIC SERVICE CENTER. Batteries,

relay panel and an optional tool box are

conveniently located below the left-side

access platform. The engine shutdown

switch is housed with the relay panel.

A compartment integrated into the access

platform contains the hood tilt actuation

switch, master switch and jump-start

receptacle.

GROUND LEVEL GREASE POINTS.

Grease fittings are grouped on the right

side of the machine in two convenient

locations – in a service compartment just

below the right-side service platform, and

a bank located just off the non-engine end

frame. These locations facilitate easy

lubrication of vital components located

throughout the machine.

AUTOLUBE. Reduce time spent on daily

maintenance and downtime for unplanned

repairs due to inadequate greasing with

the optional Caterpillar Automatic

Lubrication System. Precise lubrication

of pins and bushings at specific intervals

improves component wear and reduces

ground contamination from excessive

greasing.

S•O•S SERVICES. Sampling valves on

the 966H allow quick access to engine,

transmission and hydraulic oils for S•O•S

analysis. Oil change intervals and other

services can be optimized according to

your work schedule, reducing downtime

and managing expenses.

REMOTE PRESSURE TAPS. Pressure taps

for the steering and hydraulic systems,

transmission (optional) and brakes are

grouped behind an access panel just

below the right-side service platform.

BRAKE WEAR INDICATORS. Axles are

equipped with standard brake wear

indicators, allowing a technician to easily

determine when it is necessary to service

the brakes.

SIGHT GAUGES. Well-protected, yet easily

visible sight gauges for the transmission,

hydraulic oil and radiator coolant allow

easy daily checks while reducing the risk

of contaminants entering the systems.

16

Easy To Maintain – Easy To Service

SERVICEABILITY