Preparing to install, Install socket post, Install companion base – B&W Trailer Hitches Companion Model 3500 User Manual

Page 2: Install pivot arms

PREPARING TO INSTALL

WARNING: Components of the Companion hitch are

heavy and cumbersome to handle. Failure to use

proper lifting techniques when moving and handling

these parts could result in property damage or

serious injury.

Check that the spacer under the locking bracket is

turned so that the hole in the spacer is positioned over

the socket post. If adjustment is needed, use a tool,

such as a screwdriver, to pry up and rotate the spacer.

Install the 1/2" x 3" cap screw (draw down bolt) into

the top of the Companion base, as shown in figure B3.

Thread the cap screw into the socket adjuster and

hand tighten until the bottom of the slot in the socket

adjuster is even with the bottom of the slot in the post

as shown in figure B4.

Locate the two plastic foot pads. Each pad attaches

to the base through a slot at the end of the base leg.

Before attachment, check the width of your bed rib by

setting the wide face the plastic foot in a bed rib, see

figure A1. If the plastic foot does not reach to the

bottom of the bed rib trough, turn the plastic foot over,

see figure A2 & A3. Locate four 1/4" machine screws,

1/4" flat washers, 1/4" lock washers and 1/4" finish

nuts. Insert the machine screw up through the bottom

of the foot pad through the slot and attach it with a

1/4" flat washer, 1/4" lock washer and a 1/4" finish nut,

see figure A3. Do not tighten hardware at this time, so

that the plastic foot is able to move back and forth in

the slot.

Secure the base to the truck bed by first tightening

the eight 1/2" cap screws attaching the socket post

into the center of the base to 80 ft−lbs. Second,

tighten the 1/2" x 3−1/2" draw−down bolt to 60 ft−lbs.

Lock the draw down bolt in place by swiveling the

locking bracket over the draw down bolt, see figure

C2.

WARNING: Check the latch pin under the truck. Make

sure that the latch pin has passed through both sides

of the socket and that the pin is covered up inside the

socket by the socket adjuster, see figure C1.

Square the Companion base legs with the ribs of the

truck. Position the plastic pads so that they are both

in line with the rib along their entire length. Tighten

the four ¼" nuts holding the pads to the base.

The socket post of the Companion hitch is designed to

have two mounting options. In most truck models, the

gooseneck socket will be forward of the axle and the

companion socket post will install towards the cab of

the truck (position 1). If your socket is located over the

axle due to the frame configuration of your truck, as it

is in the 2013 RAM 3500 trucks, install your socket

post so the post is towards the rear of the truck.

(position 2), see figure B1.

Once you have established in which orientation the

socket post should be installed, locate the socket post

and eight 1/2" cap screws and 1/2" lock washers.

Slide the socket post into the bottom of the

Companion base and attach the socket post to the

base with the eight 1/2" cap screws and lock washers.

See figure B2. Do not fully tighten hardware at this

time.

INSTALL SOCKET POST

Carefully lift and position the Companion base into the

GN hitch socket in the back of the truck bed. Orient

the base so that the large warning label and the

socket post are on or facing the cab side of the truck.

Re−engage the GN latch pin handle in the driver side

fender.

NOTICE: DO NOT lubricate the draw down bolt, the

torque value is for dry threads only.

WARNING: B&W also recommends that you check

the clearance between the bed side and the underside

of the front of the trailer and to allow adequate

clearance for the pitch and roll of the trailer while

towing.

Locate both pivot arms, the four ½" threaded blocks,

eight ½" cap screws, and eight ½" split lock washers.

Place the lock washers over the cap screws. Align the

flat side of the pivot arm flat against the bolt plate and

install four 1/2" cap screws through the holes on the

arm, holding the arm in place. The holes on one side

of the threaded block have a tapered edge for starting

screws. Pass the threaded blocks through the leg and

align the blocks with each set of screws and start each

screw. After all screws are started through the arms,

torque each bolt to 80 ft−lbs.

WARNING: B&W recommends that you check the

clearance between the truck cab and the trailer.

Compare the measurement taken from the center of

the Coupler to the cab, to the measurement taken

from the center of the king pin to the farthest forward

corner point of the trailer. These measurements will

allow you to see how much clearance you will have

between the cab and the trailer while towing and

turning.

1.

3.

2.

1.

3.

4.

5.

6.

1.

2.

INSTALL COMPANION BASE

NOTICE: If truck is equipped with a removable bed liner

or mat, it should be removed or it must be cut to allow the

base to directly connect with the bed. It is acceptable to

install the RV base over a spray−in bed liner.

Check that the bed of the truck is clean, and that all

debris is removed before beginning installation.

INSTALL PIVOT ARMS

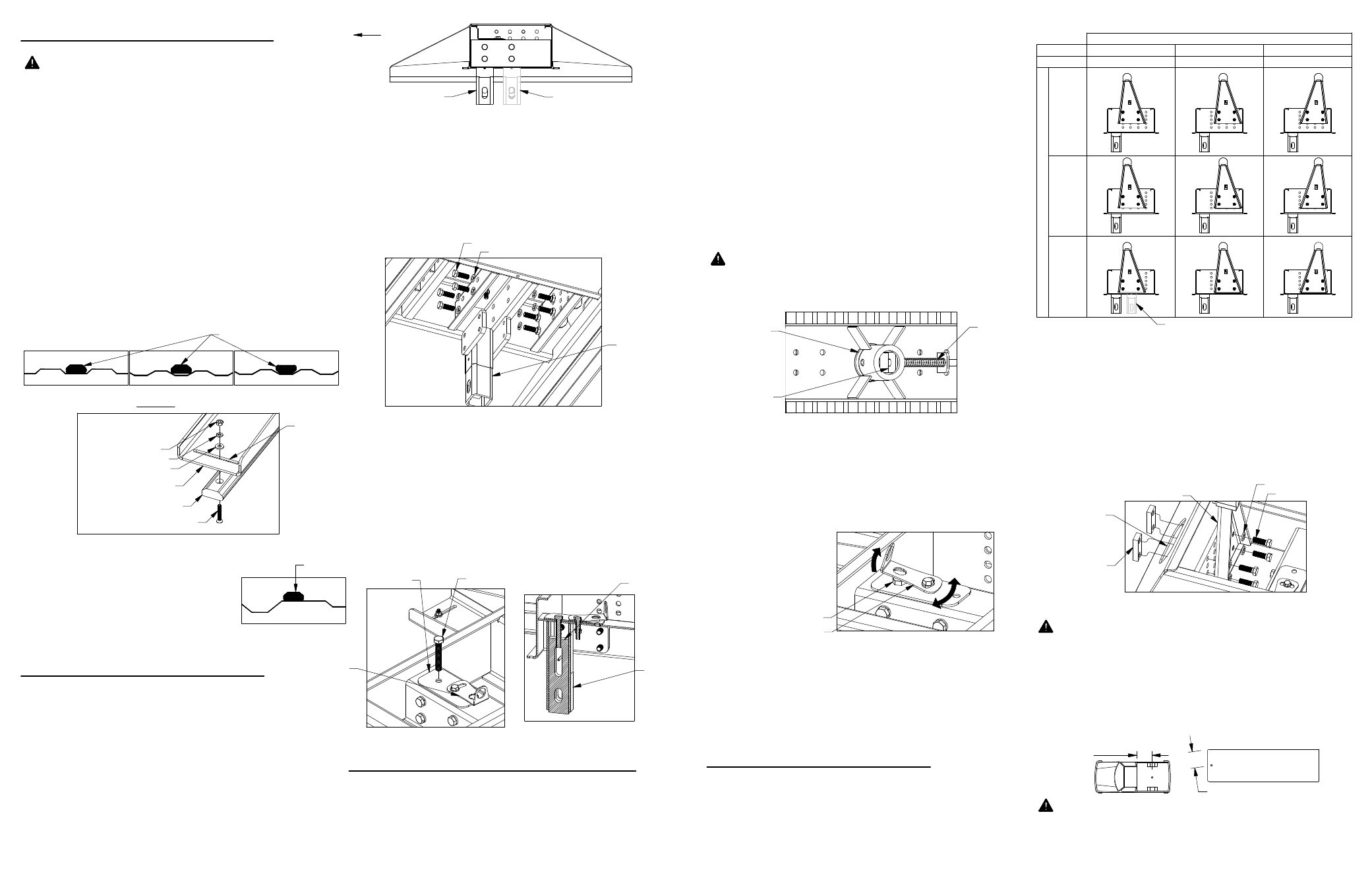

Mount the pivot arms using one of the nine different

locations illustrated in Table C1. These nine locations

allow flexibility in coupler height (vertical adjustment)

and distance from the cab (horizontal adjustment).

Choose a location so that your trailer will be as level

as possible and have adequate turning clearance

while towing. See warnings after step 2.

Locate the GN latch pin handle of the Turnoverball™

Gooseneck Hitch in the driver’s side fender well.

Retract the GN latch pin handle all the way to

disengage the pin from ball. Remove the

Turnoverball from the GN hitch receiver socket.

2.

NOTICE: Failure to "lock" the draw down bolt with the

locking bracket will allow the draw−down bolt to

loosen. Property damage may result when the base is

not properly clamped to the truckbed.

NOTICE: Nissan Titan trucks:

Due to the configuration of the bed

ribs on Nisan Titan trucks, it will be

necessary for the foot pad to be

installed on top of a bed rib, see

figure A5.

NOTICE: If the Companion is to be used in conjunction

with a 1257 or 1309 model gooseneck hitch, call the

factory for a post that is compatible with these hitches.

FIGURE A4, Plastic foot pad installation.

FIGURE B2: View of base looking up at the bottom.

FIGURE A3

Narrow rib orientation.

FIGURE A1:

Wide rib orientation.

FIGURE C1: Typical view of Turnoverball

gooseneck center under bed.

FIGURE C2: View of top of base.

FIGURE C2: View looking at passenger

pivot arm mounting location.

FIGURE A2

Incorrect orientation.

V

E

R

T

IC

A

L

A

D

JU

S

T

M

E

N

T

HORIZONTAL ADJUSTMENT

H

IG

H

E

S

T

P

O

S

IT

IO

N

S

(1

8

1/

4"

)

LO

W

E

S

T

P

O

S

IT

IO

N

S

(1

6

1/

4"

)

M

E

D

IU

M

H

E

IG

H

T

P

O

S

IT

IO

N

S

(1

7

1/

4"

)

TABLE C1: Pivot arm position table

Kingpin

3"

behind post

Kingpin

3"

behind post

Kingpin

7"

behind post

Kingpin

1"

behind post

Kingpin

5"

behind post

Kingpin

1"

ahead of post

POSITION 2

POSITION 1

FIGURE B1: Cutaway view of Companion base with

both socket post positions shown.

FIGURE A5:

Titan rib configuration.

FIGURE B3: View of center of base

FIGURE B4: Cutaway

view of center of base.

BASE LEG

PLASTIC FOOT PAD

1/4" MACHINED SCREW

1/4" FLAT WASHER

1/4" LOCK WASHER

1/4" FINISH NUT

SOCKET

PIN

SOCKET

ADJUSTER

SOCKET

POST

1/2" LOCK WASHER

1/2" CAP SCREW

1/2" X 3" CAP SCREW

CENTER OF

COUPLER

TO CAB

KING PIN TO EDGE OF TRAILER

PLASTIC FOOT PAD

FOOT

SLOT

LOCKING BRACKET

1/2" DRAW DOWN BOLT

1/2"

THREADED

BLOCK

HOLE IN

BASE LEG

PIVOT ARM

1/2" LOCK WASHER

1/2" CAP SCREW

POSITION 2

POSITION 2

PLASTIC

FOOT PAD

POSITION 1

CAB SIDE

OF TRUCK

SPACER

LOCKING

BRACKET

SOCKET

POST

SOCKET

ADJUSTER