Model 1111, Before installing, Attention – B&W Trailer Hitches Turnoverball Model 1111 (Ford) User Manual

Page 2: Turnoverball, Gooseneck hitch installation instructions, Call or email us for installation support, Step 12 - re-engage latch pin handle, Step 11 – re-attach exhaust, Step 9 – install latch pin release handle, Overhead lifting device

Model 1111

Copyright 2013

B&W Custom Truck Beds, Inc.

ALL RIGHTS RESERVED

1111 - 08 28 2013

www.turnoverball.com

Call or Email us for Installation Support

800.248.6564

Turnoverball

TM

Gooseneck Hitch Installation Instructions

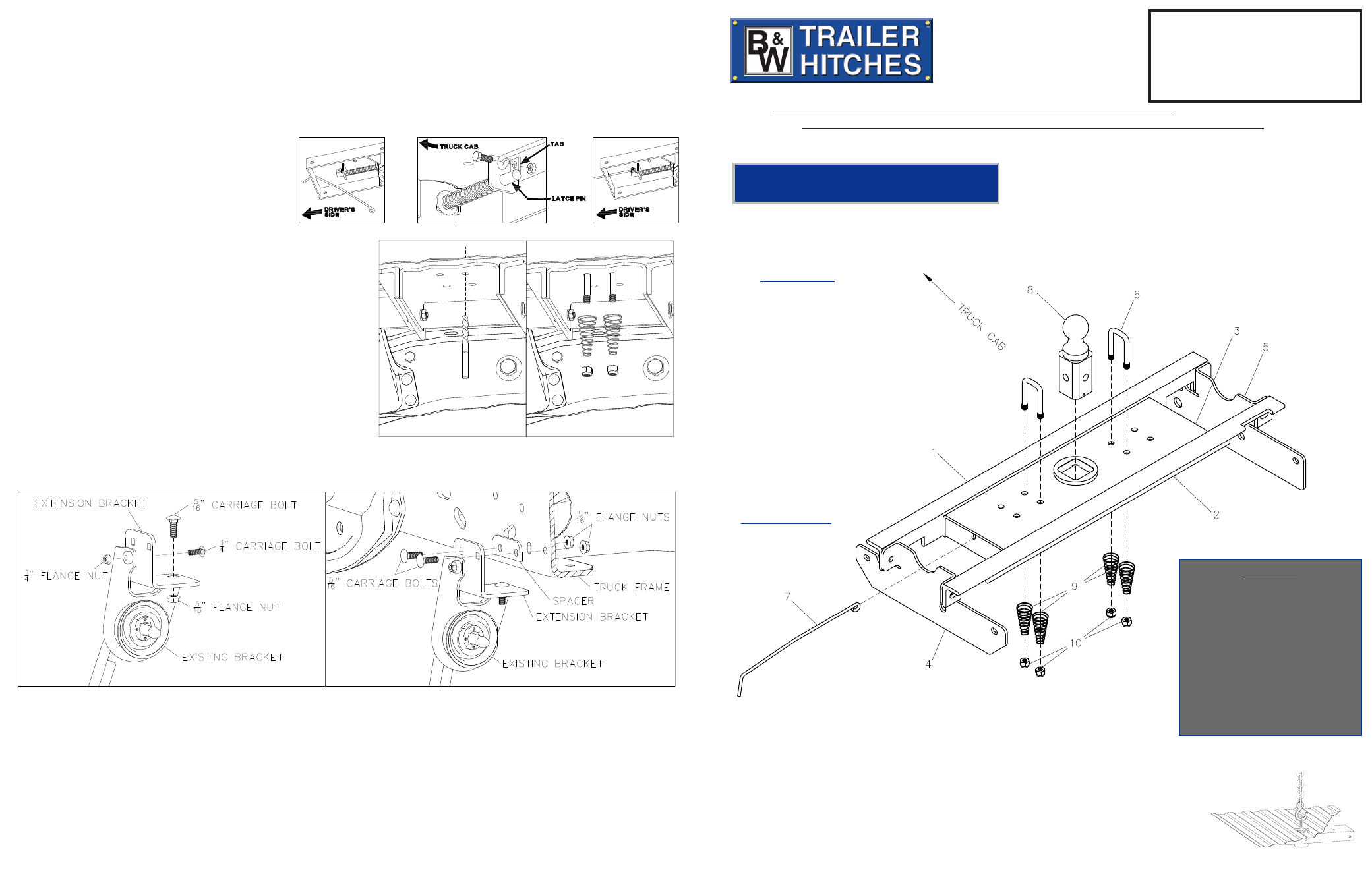

Parts List

1 - Front Crossmember

2 - Rear Crossmember

3 - Center Section

4 - Driver’s Side Sideplate

5 - Passenger’s Side Sideplate

6 - Safety Chain U-Bolts

7 - Latch Pin Handle

8 - 2-5/16” Ball

9 - Springs

10 - 1/2” Lock nuts

STEP 12 - RE-ENGAGE LATCH PIN HANDLE

Retract the latch pin by pulling the handle all the way out until it stops and then rotate it clockwise. Place the 2-5/16” Ball in the

hitch receiver. Engage the latch pin by rotating the handle counterclockwise. Be certain the latch pin passes through the holes in

the 2-5/16” Ball and fully engages through the hitch receiver. Remove and grease the square base of the 2-5/16” Ball.

B&W Trailer Hitches

1216 HWY 224 / PO Box 186

Humboldt, KS 66748

P:620.473.3664

F:620.473.3766

Ford Super Duty 2011-2014

3/4 & 1 Ton, Short & Long Bed

F-450 w/Factory Installed Bed

STEP 10 – INSTALL SAFETY CHAIN U-BOLTS

To install the safety chain U-bolts, it is necessary to drill four ½” holes

through the truck bed floor. Drill the holes from beneath the truck,

through the two holes located on each side and closest to the round

receiver tube in the center section. This will locate the safety chain

U-bolt in the lowest point of the floor corrugation. After you drill the

four holes, clean the burrs from around the holes in the top of the

bed, then drop a U-bolt through each pair of holes. Place a spring and

lock nut on each of the four legs. Tighten the nuts until flush with the

bottom of the U-bolts.

STEP 13 - Reinstall the spare tire heat shield and spare tire.

Diagram 11.1. Attach the supplied extension bracket to the

existing tail pipe bracket.

Diagram 11.2. Attach the supplied extension bracket to the frame,

using the same hole used by the factory bracket and the hole directly

right of it. Not all truck models will have the hole directly to the

right. In this case, attaching the bracket with one bolt is sufficient.

STEP 11 – RE-ATTACH EXHAUST

In

pickups equipped with a diesel engine, the exhaust may have to be lowered to allow clearance for the Turnoverball™ Hitch.

See Diagrams 11.1 and 11.2.

STEP 9 – INSTALL LATCH PIN RELEASE HANDLE

WARNING: LATCH PIN WILL NOT FUNCTION PROPERLY IF HANDLE IS NOT INSTALLED CORRECTLY.

Install the handle from underneath the truck by inserting it through the slot in the end of the center section toward the driver’s side

rear tire as shown. Attach the handle to the latch pin as shown with the handle on the “cab side” of the square tab welded to the pin.

The head of the bolt must be on the handle side, and the

lock nut must be on the tab side. The tab is welded to the

pin in an offset position so that the handle will be lined

up over the center of the pin. If the handle is fastened

to the other side of the tab, the handle will not function

properly. When installed correctly the latch pin may be

disengaged from the ball by pulling on the handle from the

driver’s side wheel well and rotating the handle clockwise.

Hardware Kit

2 ea. - 3/4” X 2 1/2” Bolts

14 ea. - 1/2” X 1 1/2” Bolts

3 ea. - 5/16” X 1 Carriage Bolts

1 ea. - 1/4” X 3/4” Carriage Bolt

1 ea. - 3/4” Flat Washer

1 ea. - 3/4” Rectangular Washer

14 ea. - 1/2” Flat Washers

2 ea. - 3/4” Lock Washers

14 ea. - 1/2” Lock Washers

2 ea. - 3/4” Nuts

14 ea. - 1/2” Nuts

3 ea. - 5/16” Flange Nut

1 ea. - 1/4” Flange Nut

2 ea. - Pipe Spacers

1 ea. - Exhaust Bracket

1 ea. - Exhaust Spacer

1 ea. - Sensor control module

relocation bracket.

Safety Chain Kit

2 ea. - 1/2” U-Bolts

4 ea. - 1/2” Lock Nuts

4 ea. - Springs

An overhead-lifting device, such as chain falls, engine hoist, or cable come-a-long, can be used

to lift the center section of the hitch in place. Lower a loop of rope or chain through the 4” hole

in the truck bed floor and attach it to the latch pin in the round hitch receiver tube in the center

section. Use the lifting device to raise the center section until the round hitch receiver tube that

protrudes from the center section fits in the 4” hole in the truck bed floor. Maintaining upward

pressure may facilitate fastening the crossmember to the center section, especially if the truck

bed floor has been distorted downward from heavy use. If you use an overhead-lifting device,

it should be disconnected before squaring the center section across the frame, installing the

sideplates and torquing fasteners.

BEFORE INSTALLING-

OVERHEAD LIFTING DEVICE

Attention:

If you intend to use a Companion 5th Wheel

RV Hitch in a 2011 Ford Truck, please call

us at 800-248-6564 for a foot pad kit that

fills voids in the truck bed rib pattern. Using

the Companion on a 2011 Ford without the

supplemental kit could result in damage to

the bed.

NOTE: We recommend reading instructions before beginning the installation.

WARNING: The tow vehicle’s towing capacities should under NO circumstances be exceeded.

STEP 8 – TIGHTEN HARDWARE

1. Tighten the center section to cross member bolts to 80 ft pounds. 2. Check to ensure the assembled center section is square with

the frame. 3. Tighten the ¾” side plate bolts to 120 ft pounds. 4. Tighten the 1/2” side plate bolts to 80 ft pounds. 5. Tighten the

side plate to angle bolts to 80 ft pounds.