B&W Trailer Hitches Turnoverball Model 1384 (Dodge) User Manual

Page 3

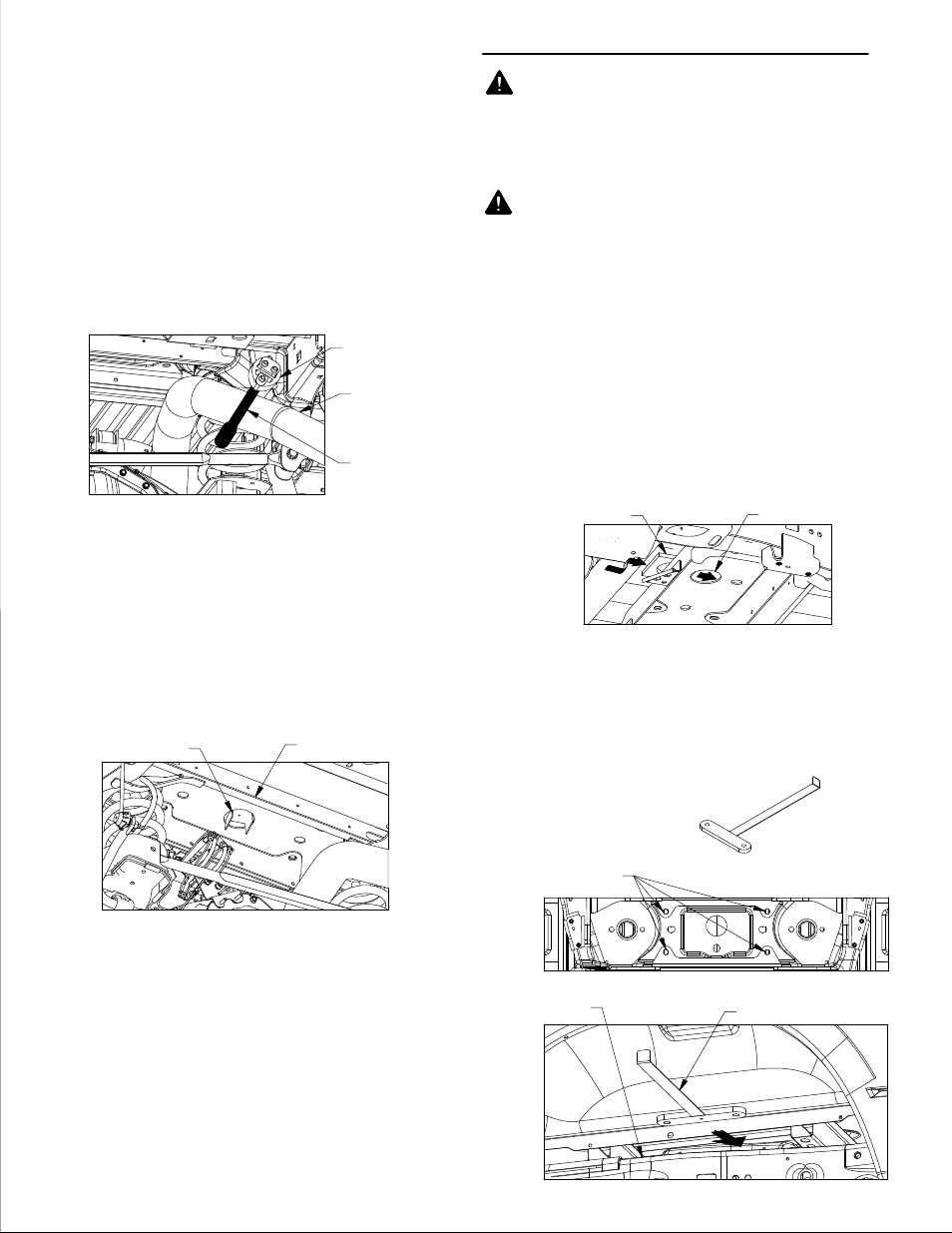

Mark the location of the 3−1/2" hole. Insert the hole

template into the center hole of the frame cross

member as shown in figure A6. Push the template

upward until it is flush against the bottom of the bed

floor. Make a mark on the truck bed floor through the

hole in the hole template using a pencil, marker, or

other tool. Once the center point is marked, remove

the template. Use a center punch to place an

indention in the truck bed at the center of the mark.

Using a drill and a ¼" bit, drill a pilot hole through the

bed in this location.

Cut the 3−1/2" diameter hole. From the top side of

the bed, use the pilot hole and a hole saw to create a

3−1/2" diameter hole in the truck bed floor. A saber

saw equipped with a metal cutting blade may also be

used if the 3−1/2" diameter circle is laid out on the bed

floor around the center of the pilot hole. Remove any

burrs created while cutting the hole. The size of the

round portion of the hitch that will be seen from the

truck bed was determined by the size of the hole in

the truck’s frame. The closest nominal hole size to this

feature is 3−1/2". The 3−1/2" hole will leave a gap

around the hitch structure. This gap will be filled in by

the plastic spacer block.

Most trucks have fuel lines, brake lines, electrical

wires or other vehicle systems located along the

frame rails or in the general area where B&W

Turnoverball hitches install. Carefully examine the

locations of these systems before installation.

Make certain that these are not damaged during

positioning hitch components, drilling holes, or

tightening fasteners. Damage to these systems

may result in property damage, serious injury, or

death.

Turnoverball hitch components are heavy and

may be cumbersome to handle. Failure to use

proper lifting techniques and caution when

handling these items could result in serious

injury.

Place spacer block. Position the plastic spacer block

between the frame cross member and the bed as

shown. See figure B1. Center the hole in the spacer

block over the hole in the frame.

Install threaded blocks. Place the threaded block,

see figure B2, between the frame cross member and

the bed, see figure B4. Use the handle welded to the

blocks to guide them into place. Make sure that the

two threaded holes in the blocks are directly over the

holes in the frame, see figure B3.

8.

9.

1.

2.

INSTALL CENTER SECTION

Remove or modify fender liners as needed.

Some vehicles are equipped with various designs

of plastic liners inside the rear wheel wells. If the

liner in the driver side wheel well prevents access

to the opening between the bed and the frame,

just over the axle, it may need to be removed or

cut to install the handle.

Disconnect the exhaust hanger: (optional, see

secure hitch section step 3) Locate the exhaust

hanger in the rear passenger portion of the truck,

see figure A5. Disconnect the exhaust from the

hanger to provide improved mounting access to

the center section. It is recommended that a pry

bar be used to aid in disconnecting the exhaust

hanger, as shown in figure A5.

6.

7.

FIGURE A5: looking under truck bed towards cab.

FIGURE A6: looking under truck bed towards cab.

FIGURE B1: Looking up at bed from foward of the driver side tire.

FIGURE B2: Threaded Block.

FIGURE B4: Looking at passenger side wheel well.

FIGURE B3: Looking up at frame crossmember under truck

EXHAUST HANGER

EXHAUST

PRY BAR

FRAME CROSSMEMBER

HOLE TEMPLATE

HOLE TEMPLATE

FRAME CROSSMEMBER

THREADED BLOCK

CENTER SECTION

MOUNTING HOLES.

TRUCK FRAME