VEGA VEGAMET 391 With SIL qualification User Manual

Page 23

23

7 Setup with the integrated display and adjustment unit

VEGAMET 391 • With SIL qualification

38704-EN-130228

→

Carry out your settings via the appropriate keys and save with

[OK].

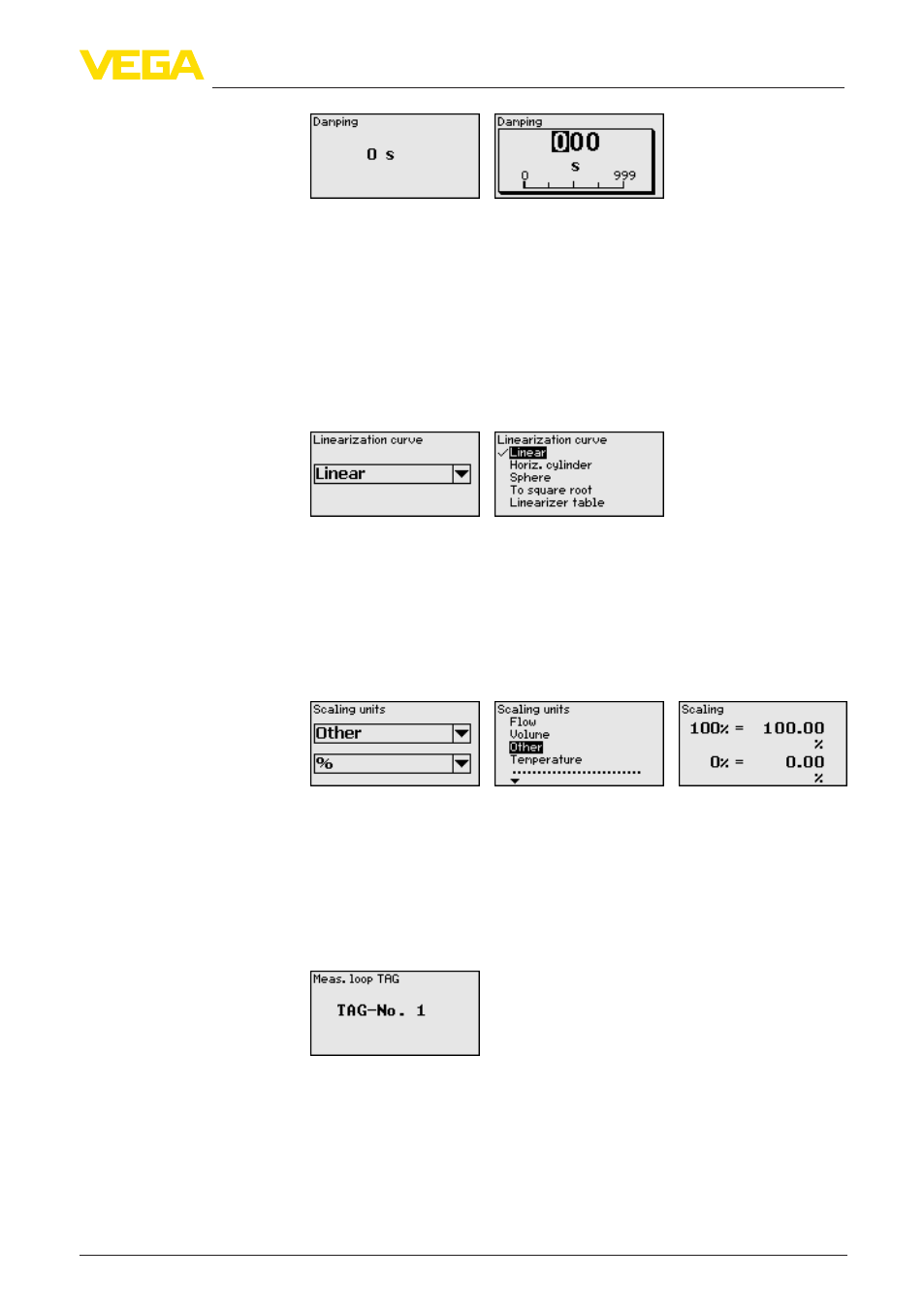

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level, for example, with a cylindrical

or spherical tank. Corresponding linearization curves are prepro-

grammed for these vessels. They represent the correlation between

the level percentage and vessel volume. By activating the appropriate

curve, the volume percentage of the vessel is displayed correctly. If

the volume should not be displayed in percent but e.g. in l or kg, a

scaling can be also set.

→

Carry out your settings via the appropriate keys and save with

[OK].

Scaling means converting the measured value into a certain param-

eter and unit. The linearized percentage value is the source signal

which is used as basis for the scaling. The indication can then show

the volume in litres e.g., instead of the percentage value. Indication

values from max. -99999 to +99999 are possible.

→

Carry out your settings via the appropriate keys and save with

[OK].

In this menu item you can enter an unambiguous designation for each

measurement loop, e.g. the measurement loop name or the tank or

product designation. In digital systems and in the documentation

of larger plants, a singular designation should be entered for exact

identification of individual measuring points.

→

Carry out your settings via the appropriate keys and save with

[OK].

The relay/current outputs are arranged under "Outputs". Keep in mind

that relays 1/2 are not integrated in the SIL safety concept.

First of all, select the requested mode ("Overfill protection/Dry run

protection" or "Pump control").

Meas. loop - Linearization

curve

Meas. loop - Scaling

Meas. loop - Meas. loop

TAG

Meas. loop - Outputs -

Relay 1/2