VEGA VEGAMET 391 With SIL qualification User Manual

Page 20

20

7 Setup with the integrated display and adjustment unit

VEGAMET 391 • With SIL qualification

38704-EN-130228

guidance. We recommend using the setup assistant for the initial

setup. If later on individual settings should be corrected or added, the

most expedient way to do this is via the classic menus.

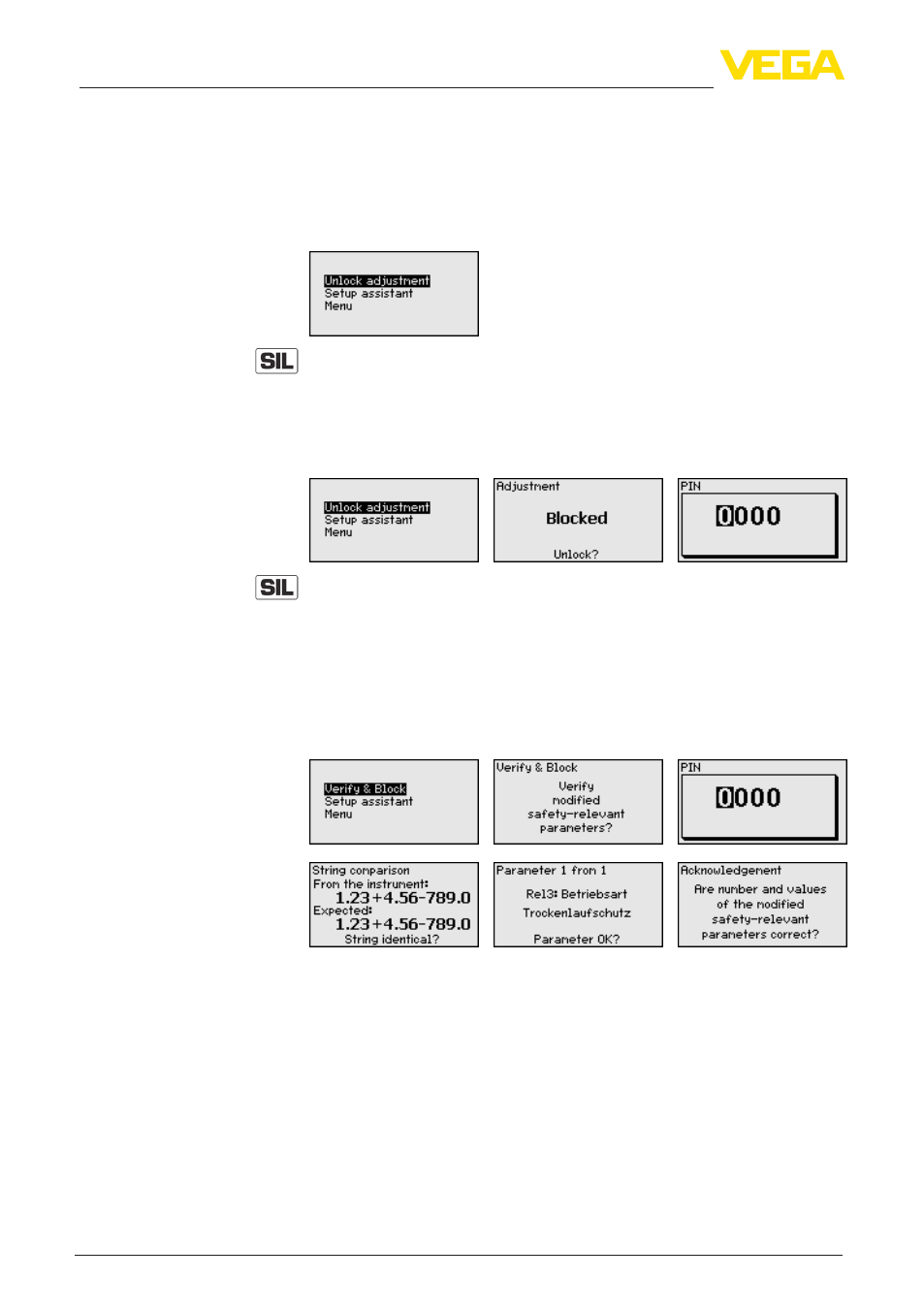

As a standard feature, the parameterization of the instrument is

locked to protect it against unauthorized operation. By selecting "Re-

lease operation" and entering a PIN, the instrument is unlocked.

All instrument settings are protected against unauthorized changes.

Execution of the safety functions is ensured only in locked mode.

Modification is thus only possible after releasing the activated lock

and a subsequent verification. The instrument is unlocked by select-

ing "Release operation" and entering a PIN. PIN "0000" is preset but

can be modified by the user.

To ensure the execution of the safety functions, the instruments must

be locked again after the parameter change. All modified, safety-rel-

evant parameters must be verified and a character string comparison

confirmed. Modifications of non safety-relevant parameters are not

shown/verified.

The following parameters of the relays 3 and 4 are classified as

safety-relevant: mode, switching point Hi, switching point Lo.

The following example shows the modification of the mode of relay 3.

The setup assistant leads you step-by-step through the standard set-

tings. The following steps are carried out:

•

Device-TAG (individually adjustable instrument name)

•

Measurement loop TAG (individually adjustable measurement loop

designation)

•

Measured variable (for example level or process pressure)

•

Min./Max. adjustment

•

Activation of the fail safe relay

•

Configuration of the relay outputs (e.g. setup of pump control or

overfill protection)

Release operation

Verify and lock

Setup assistant