VEGA VEGAMET 391 With SIL qualification User Manual

Page 22

22

7 Setup with the integrated display and adjustment unit

VEGAMET 391 • With SIL qualification

38704-EN-130228

Through the adjustment, the input value of the connected sensor is

converted into a percentage value. This conversion steps allows to

image any individual input value range to a relative range (0 % to

100 %). With the adjustment in mA, two sensor current values are

entered which correspond ideally to the levels 0 % and 100 %. As

an alternative, sensor current values corresponding to any level in

percent can be entered. The greater the difference between these

values, the more exact the measurement will be.

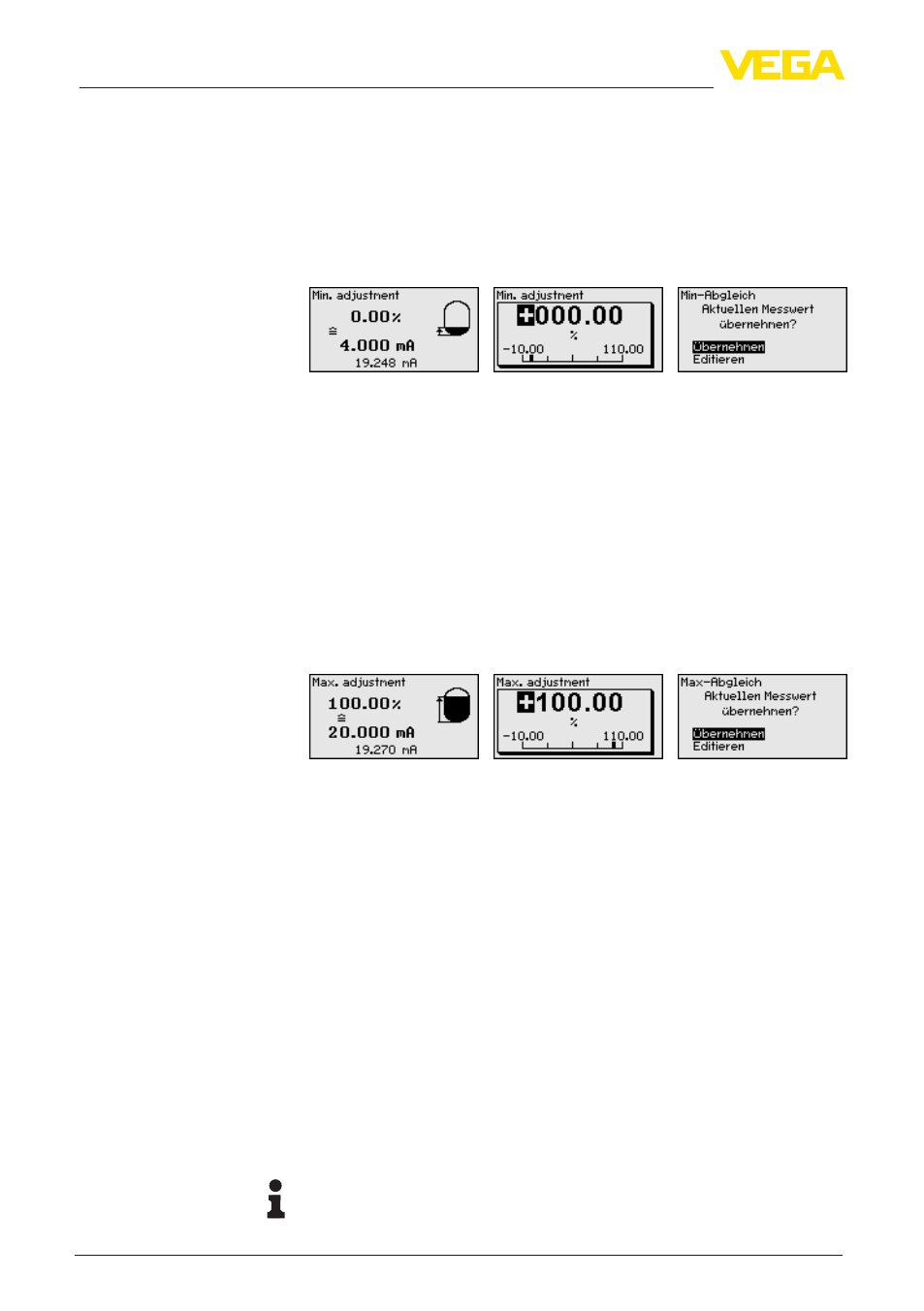

1. With

[OK] you prepare the percentage value for editing, with [->]

you place the cursor to the requested position. Set the requested

percentage value with [+] and save with [OK].

2. After entering the percentage value for the min. adjustment, the

suitable current value must be entered. If you want to use the

currently measured value, select the menu item "Accept" (live ad-

justment or adjustment with medium). If the adjustment should be

carried out independently of the measured level, then select the

option "Edit". Now enter the current value in mA that is suitable

for the percentage value (dry adjustment i.e. adjustment without

medium).

3. Save your settings with [OK] and move to "Max. adjustment" with

[->].

4. As described previously, enter now the percentage value for max.

adjustment and confirm with [OK].

5. After entering the percentage value for the max. adjustment, the

suitable current value must be entered. If you want to use the

currently measured distance value, select the menu item "Accept"

(live adjustment or adjustment with medium). If the adjustment

should be carried out independently of the measured level, then

select the option "Edit". Now enter the current value in mA that is

suitable for the percentage value (dry adjustment i.e. adjustment

without medium).

6. Finally save your settings with [OK], the adjustment is finished.

To suppress fluctuations in the measured value display, e.g. caused

by an agitated product surface, an integration time can be set. This

time can be between 0 and 999 seconds. Remember that the reaction

time of the entire measurement will then be longer and the sensor will

react to measured value changes with a delay. In general, a period of

a few seconds is sufficient to smooth the measured value display.

Note:

The damping does not influence all safety-relevant outputs (relay 3/4,

current output).

Meas. loop - Adjustment

Meas. loop - Damping