7 basic adjustment, mode range optimization, 8 protocol of the optimization, 6 fault signal – VEGA VEGASON 71 - D User Manual

Page 38

VEGASON 71 - D

38

9 Optimization

9.7

Basic adjustment, mode range

optimization

All parameters, their data modified during an optimization

can be reset to factory setting if necessary.

Programming example

•

Enquire mode

1 - 27

in the MODEFIELD

•

Modify figure

0

to figure

1

in the PARAMETER FIELD

•

Then activate the basic adjustment with key STO

Influences

-

CAL (flashing) appears for approx. 3 secs. on the

display.

-

All modes of the optimization are reset to factory setting

(see protocol)

-

The measuring system starts a new feeding phase,

therefore the fail safe relay de-energizes and the failure

LED lights.

-

CAL

extinguishes after 3 secs. and the figures

0.000

remain displayed.

-

This means, basic adjustment activated, feeding phase

started.

-

After approx. 1 … 3 mins. the operating status is

reached again. The fault signal extinguishes and the

measuring system operates with the parameters of the

factory setting.

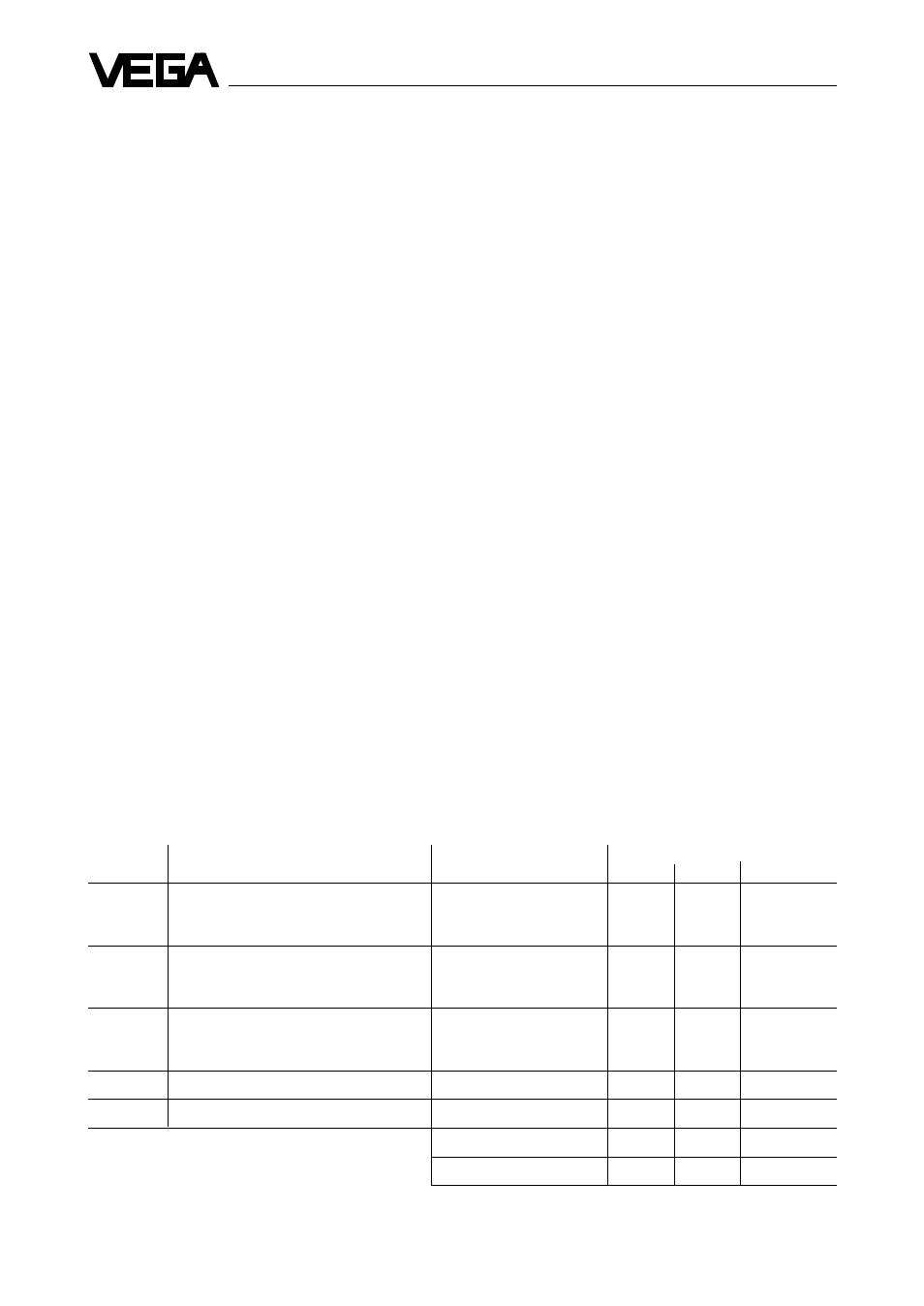

9.8

Protocol of the optimization

Mode-no.

Mode description

Factory setting

Optimization

1

2

3

Operating range

1 - 07

- begin of operating range ...................

0.000

m

1 - 08

- end of operating range ......................

6.000

m

Multiple echo reduction

1 - 12

- reduction in Volt .................................

0.00

1 - 13

- optimization in Volt ............................

0.00

Max. gain

1 - 21

- limitation in Volt .................................

0.03

1 - 22

- optimization in Volt ............................

0.03

1 - 24

Fault signal ..........................................

0

(off)

1 - 27

Basic adjustment .................................

0

(off)

Date

Name

9.6

Fault signal

The fault signal is triggered when the measuring reliability

is not ensured. The measuring reliability is calculated out

of the ratio echo measurement to noise level

measurement.

The fault signal can be varied as follows:

Explanation in case of fault

Fault signal of mode

1 - 24

=

0

(factory setting)

- Indication of the error code on the display.

- The last as correct detected measured value is stored.

- With the detection of a new correct echo, the last stored

value is cancelled and the actual value is indicated.

Fault signal ON mode

1 - 24

=

1

- Indication of the error code on the display.

- The fail safe relay de-energizes.

- The signal LED lights.

- With the detection of a new correct echo, the fleeding

phase is automatically started and after it is finished an

actual measured value is given.

In both cases the relay and current outputs react acc. to

the failure processing given in mode

0 - 93

.

Programming example

• Enquire mode

1 - 24

in the MODEFIELD

• Program fault signal ON with

1

in the PARAMETER

FIELD

• Then store with STO