5 socket extensions – VEGA VEGASON 54P…56P Profibus PA User Manual

Page 20

20

VEGASON 54P … 56P

2.5 Socket extensions

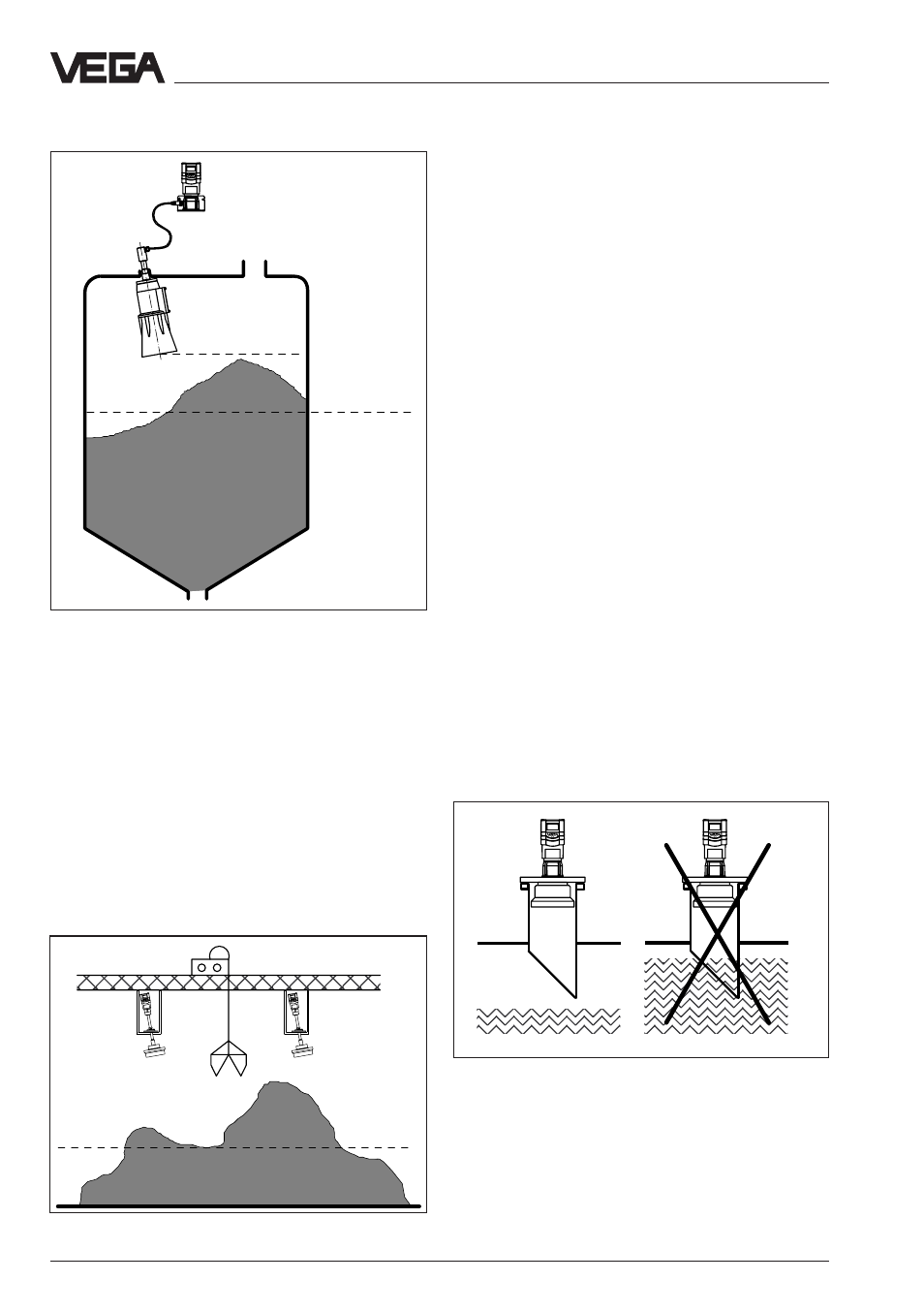

Ultrasonic sensors require a min. distance to

the liquid or solid. Take the min. distance into

account in your planning. In some situations,

it is possible to reach the required min. dis-

tance, and hence the desired filling height

with a socket extension. However, the socket

piece increases the noise level of the ultra-

sonic signal at the extension outlet and can

interfere with the measurement. Only use a

socket extension if all other possibilities have

to be excluded. Carry out the extension as

shown in the following illustration.

Socket extensions for liquids

Chamfer and deburr the socket carefully and

make sure that it has a smooth inner surface.

The socket should not protrude into the

measured product, in case buildup can form

on the socket through dirt or product

residues.

For non-adhesive measured products, a

socket extension in the form of a measuring

tube can be permanently submerged in the

product. The ultrasonic measurement is then

made exclusively in the measuring tube and

works very well without interference from

other vessel installations (see "Pump shaft").

Socket piece should not be immersed into adhesive

products (figure: VEGASON 54)

VEGASON 56 in 1" mounting boss.

Reference plane

Min. distance

Mounting and installation

Mounting boss

The socket axis should be oriented to the

product surface. More suitable is the use of a

swivelling holder version (type B, C), as

described on previous pages.

Material heaps

Large material heaps are usually measured

with several instruments, which can be

mounted on e.g. traverse cranes. If material

cones form, we recommend orienting the

sensors to the solid surface.

Transducer on traverse crane above a material heap