Operation – Bosch GWS 18-125 V-LI Professional User Manual

Page 21

22 | English

1 609 92A 01F | (10.1.13)

Bosch Power Tools

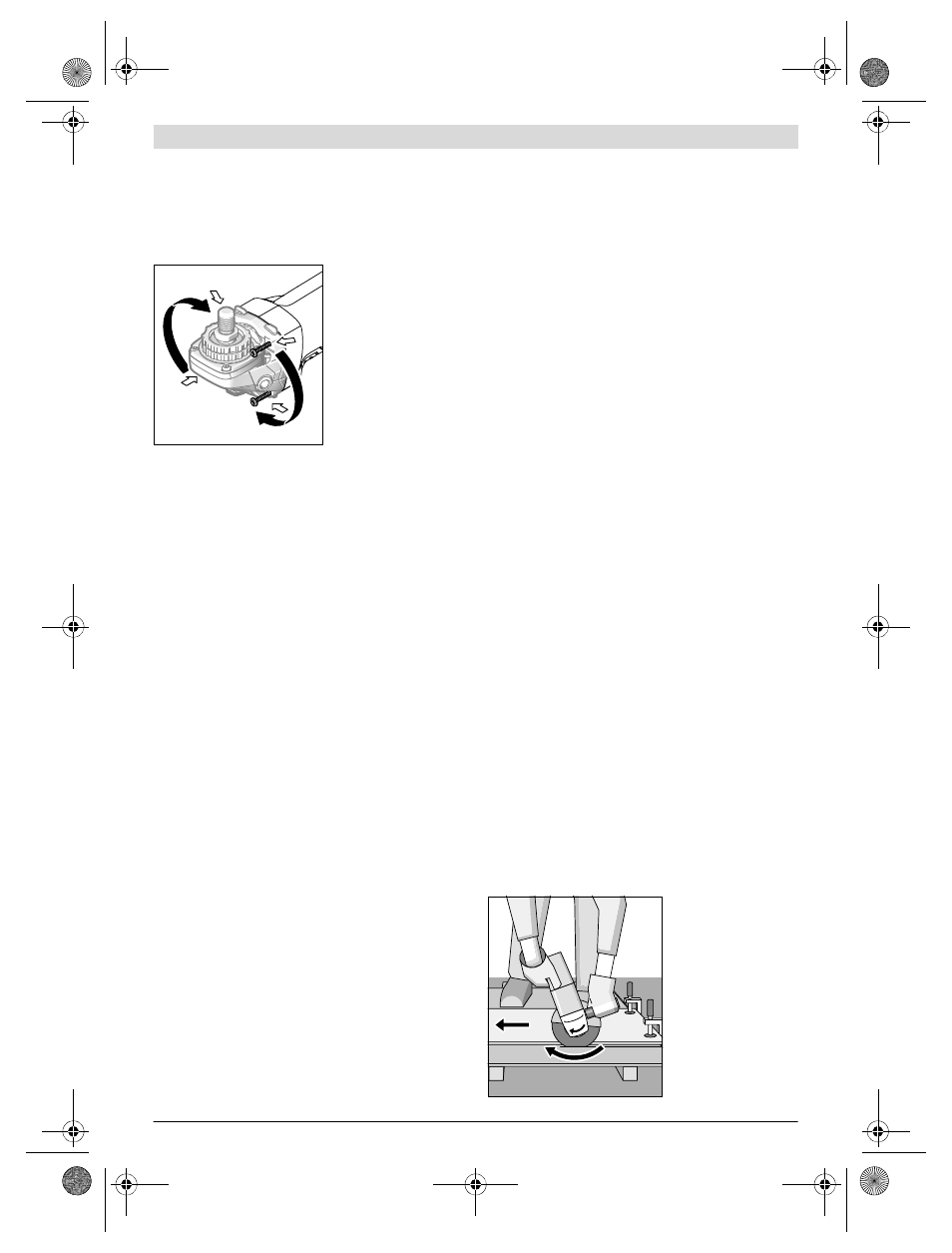

Rotating the Machine Head

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

The machine head can be

rotated with respect to

the machine housing in

90° steps. In this man-

ner, the On/Off switch

can be brought into a

more convenient position

for special working situa-

tions, e.g. for left-handed

persons.

Completely unscrew the

four screws. Rotate the

machine head carefully,

without removing it from the hous-

ing, to the new position. Screw in and tighten the four screws

again.

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Operation

Starting Operation

Inserting the battery

Use only original Bosch lithium ion batteries with the

voltage listed on the nameplate of your power tool. Us-

ing other batteries can lead to injuries and pose a fire haz-

ard.

Insert the charged battery

5 from the front into the base of the

power tool until the battery is securely locked.

Switching On and Off

To

start the power tool, push the On/Off switch 3 forwards.

To

lock the On/Off switch 3, press the On/Off switch 3 down

at the front until it latches.

To

switch off the power tool, release the On/Off switch 3 or,

if it is locked, briefly push down the back of the On/Off switch

3 and then release it.

To save energy, only switch the power tool on when using it.

Check grinding tools before using. The grinding tool

must be mounted properly and be able to move freely.

Carry out a test run for at least one minute with no load.

Do not use damaged, out-of-centre or vibrating grind-

ing tools. Damaged grinding tools can burst and cause in-

juries.

Working Advice

Exercise caution when cutting slots in structural walls;

see Section “Information on Structures”.

Clamp the workpiece if it does not remain stationary

due to its own weight.

Do not strain the machine so heavily that it comes to a

standstill.

After heavily straining the power tool, continue to run it at

no-load for several minutes to cool down the accessory.

Do not touch grinding and cutting discs before they

have cooled down. The discs can become very hot while

working.

Do not use the power tool with a cut-off stand.

When the power tool is electrostatically charged, the built-in

electronic control switches it off. To restart the power tool,

press the On/Off switch

3 again.

Rough Grinding

Never use a cutting disc for roughing.

The best roughing results are achieved when setting the ma-

chine at an angle of 30° to 40°. Move the machine back and

forth with moderate pressure. In this manner, the workpiece

will not become too hot, does not discolour and no grooves

are formed.

Flap Disc

With the flap disc (accessory), curved surfaces and profiles

can be worked.

Flap discs have a considerably higher service life, lower noise

levels and lower sanding temperatures than conventional

sanding sheets.

Cutting Metal

For cutting with bonded abrasives, always use the pro-

tection guard for cutting 16.

When cutting, work with moderate feed, adapted to the mate-

rial being cut. Do not exert pressure onto the cutting disc, tilt

or oscillate the machine.

Do not reduce the speed of running down cutting discs by ap-

plying sideward pressure.

The machine must al-

ways work in an up-

grinding motion. Other-

wise, the danger exists

of it being pushed

un-

controlled out of the

cut.

When cutting profiles

and square bar, it is best

to start at the smallest

cross section.

OBJ_BUCH-1102-005.book Page 22 Thursday, January 10, 2013 11:03 AM