Bosch GWS 18-125 V-LI Professional User Manual

Page 20

English |

21

Bosch Power Tools

1 609 92A 01F | (10.1.13)

Clean the grinder spindle

8 and all parts to be mounted.

For clamping and loosening the grinding tools, lock the grind-

er spindle with the spindle lock button

2.

Actuate the spindle lock button only when the grinder

spindle is at a standstill. Otherwise, the machine may be-

come damaged.

Grinding/Cutting Disc

Pay attention to the dimensions of the grinding tools. The

mounting hole diameter must fit the mounting flange without

play. Do not use reducers or adapters.

When using diamond cutting discs, pay attention that the di-

rection-of-rotation arrow on the diamond cutting disc and the

direction of rotation of the machine (see direction-of-rotation

arrow on the machine head) agree.

See graphics page for the mounting sequence.

To fasten the grinding/cutting disc, screw on the clamping nut

13 and tighten with the two-pin spanner; see Section “Quick-

clamping Nut ”.

After mounting the grinding tool and before switching

on, check that the grinding tool is correctly mounted

and that it can turn freely. Make sure that the grinding

tool does not graze against the protection guard or oth-

er parts.

A plastic part (O-ring) is fitted around

the centring collar of mounting flange

11. If the O-ring is missing or dam-

aged, the mounting flange 11 must be

replaced before resuming operation.

Flap Disc

For operations with the flap disc, always mount the

hand guard 18.

Rubber Sanding Plate

For operations with the rubber sanding plate 19, al-

ways mount the hand guard 18.

See graphics page for the mounting sequence.

Screw on the round nut

21 and tighten with the two-pin span-

ner.

Cup Brush/Disc Brush

For operations with the cup brush/wheel brush, always

mount the hand guard 18.

See graphics page for the mounting sequence.

The cup brush/disc brush must be able to be screwed onto

the grinder spindle until it rests firmly against the grinder

spindle flange at the end of the grinder spindle threads. Tight-

en the cup brush/disc brush with an open-end spanner.

Quick-clamping Nut

For convenient changing of grinding tools without the use of

additional tools, you can use the quick-clamping nut

14 in-

stead of the clamping nut

13.

The quick-clamping nut 14 may be used only for grind-

ing or cutting discs.

Use only a flawless, undamaged quick-clamping nut 14.

When screwing on, pay attention that the side of the

quick-clamping nut 14 with printing does not face the

grinding disc; the arrow must point to the index mark

28.

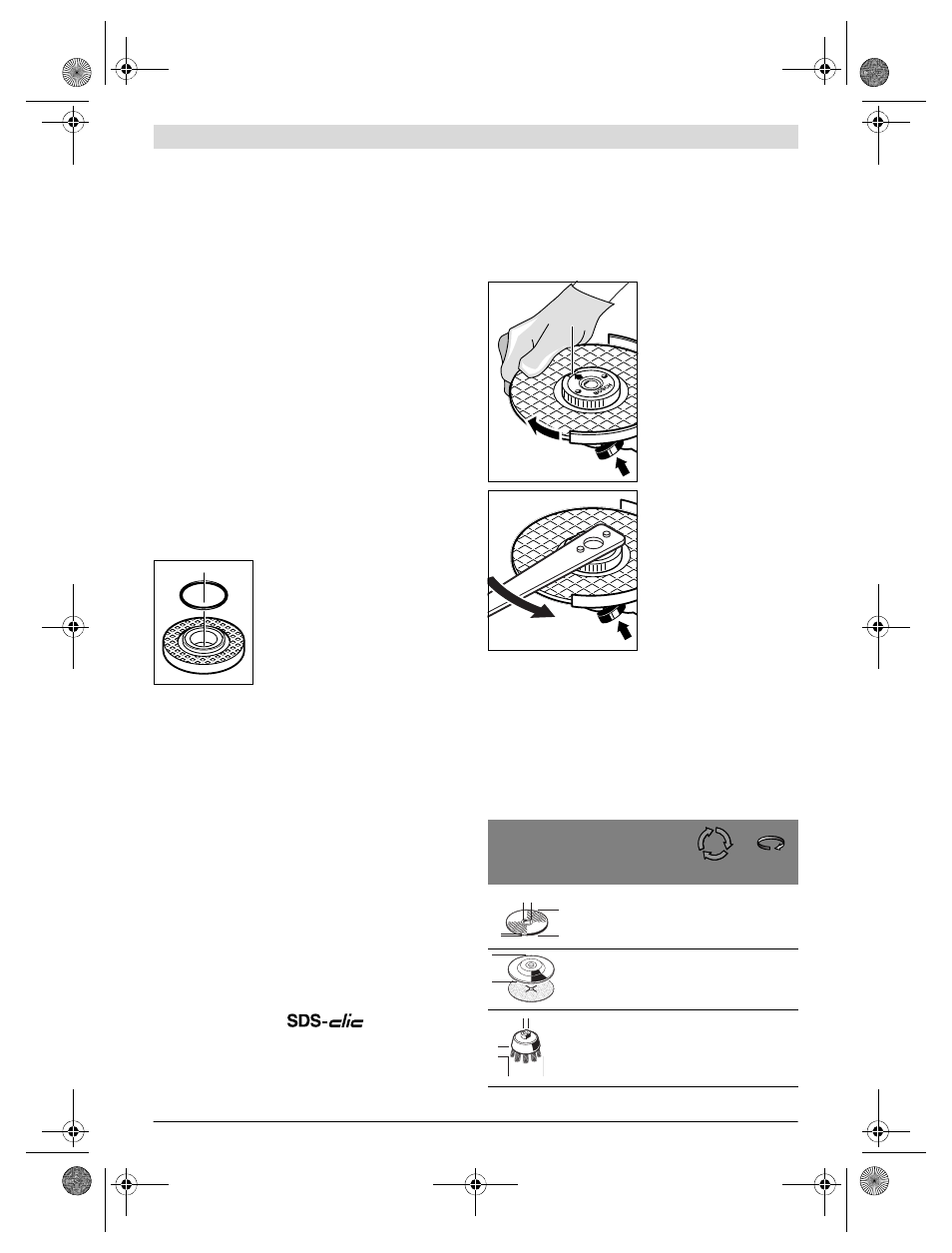

Lock the grinder spindle with

the spindle lock button

2. To

tighten the quick-clamping

nut, firmly turn the grinding

disc in clockwise direction.

A properly attached, undam-

aged quick-clamping nut can

be loosened by hand when

turning the knurled ring in an-

ticlockwise direction.

Never loosen a tight quick-

clamping nut with pliers. Al-

ways use the two-pin span-

ner. Insert the two-pin span-

ner as shown in the

illustration.

Approved Grinding Tools

All grinding tools mentioned in these operating instructions

can be used.

The permissible speed [min

-1

] or the circumferential speed

[m/s] of the grinding tools used must at least match the values

given in the table.

Therefore, observe the permissible

rotational/circumferen-

tial speed on the label of the grinding tool.

max.

[mm]

[mm]

D

b

d

[min

-1

]

[m/s]

115

125

6

6

22.2

22.2

10000

10000

80

80

115

125

–

–

–

–

10000

10000

80

80

75

30

M 14

10000

45

28

b

d

D

D

D

b

d

OBJ_BUCH-1102-005.book Page 21 Thursday, January 10, 2013 11:03 AM