Bosch GWS 18-125 V-LI Professional User Manual

Page 19

20 | English

1 609 92A 01F | (10.1.13)

Bosch Power Tools

Note: The battery is supplied partially charged. To ensure full

capacity of the battery, completely charge the battery in the

battery charger before using your power tool for the first time.

The Lithium-Ion battery can be charged at any time without

reducing its service life. Interrupting the charging procedure

does not damage the battery.

The Lithium-Ion battery is protected against deep discharging

by the “Electronic Cell Protection (ECP)”. When the battery is

empty, the machine is switched off by means of a protective

circuit: The inserted tool no longer rotates.

Do not continue to press the On/Off switch after the

machine has been automatically switched off. The bat-

tery can be damaged.

The battery is equipped with a NTC temperature control

which allows charging only within a temperature range of be-

tween 0 °C and 45 °C. A long battery service life is achieved

in this manner.

Observe the notes for disposal.

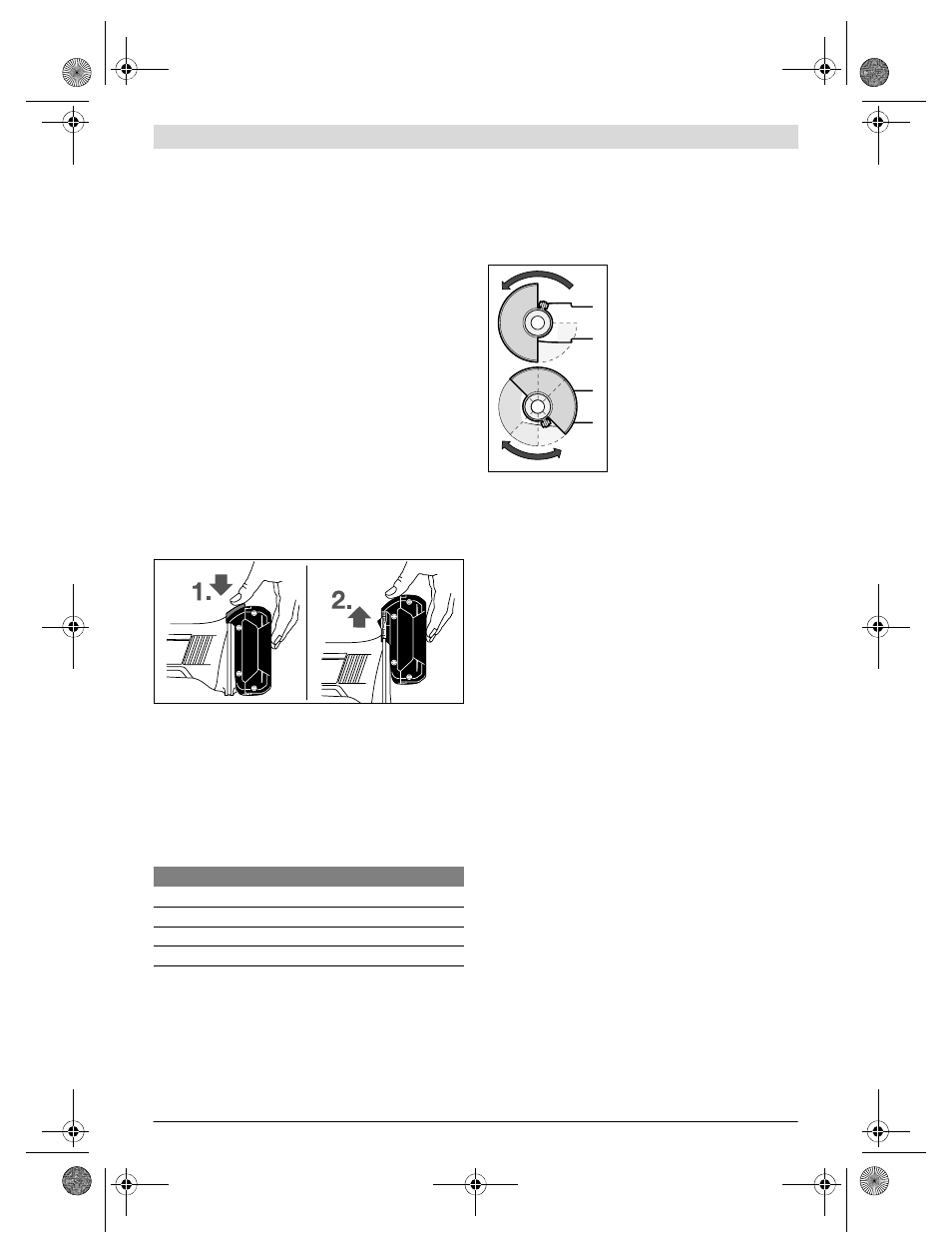

Removing the battery

The battery

5 is equipped with two locking levels that should

prevent the battery from falling out when pushing the battery

unlocking button

6 unintentionally. As long as the battery is

inserted in the power tool, it is held in position by means of a

spring.

To remove the battery

5, press the unlocking button 6 and

pull out the battery toward the front.

Do not exert any force.

Battery Charge-control Indication (see figure A)

The three green LEDs of the battery charge-control indicator

24 indicate the charge condition of the battery 5. For safety

reasons, it is only possible to check the status of the charge

condition when the machine is at a standstill.

Press button

23 to indicate the charge condition. This is also

possible when the battery

5 is removed.

When no LED lights up after pushing button

23, then the bat-

tery is defective and must be replaced.

Mounting the Protective Devices

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

Note: After breakage of the grinding disc during operation or

damage to the holding fixtures on the protection guard/power

tool, the machine must promptly be sent to an after-sales ser-

vice agent for maintenance for addresses, see section “After-

sales Service and Application Service”.

Protection Guard for Grinding

Place the protection guard

10 on

the spindle collar. Adjust the posi-

tion of the protection guard

10 to

the requirements of the operation.

Lock the protection guard

10 tight-

ening the locking screw

9 with an al-

len key

4.

Adjust the protection guard 10 in such a manner that

sparking is prevented in the direction of the operator.

Note: The encoding keys on the protection guard 10 ensure

that only a protection guard that fits the machine type can be

mounted.

Protection Guard for Cutting

For cutting with bonded abrasives, always use the pro-

tection guard for cutting 16.

Provide for sufficient dust extraction when cutting

stone.

The protection guard for cutting

16 is mounted in the same

manner as the protection guard for grinding

10.

Cutting Guide with Dust Extraction Protection Guard

The cutting guide with dust extraction protection guard

26 is

mounted in the same manner as the protection guard for

grinding

10.

Auxiliary Handle

Operate your machine only with the auxiliary handle 7.

Screw the auxiliary handle

7 on the right or left of the machine

head depending on the working method.

Hand Guard

For operations with the rubber sanding plate 19 or with

the cup brush/wheel brush/flap disc, always mount the

hand guard 18.

The hand guard

18 is fastened with the auxiliary handle 7.

Mounting the Grinding Tools

Before any work on the machine itself (e. g. mainte-

nance, tool change, etc.) as well as during transport

and storage, remove the battery from the power tool.

There is danger of injury when unintentionally actuating

the On/Off switch.

Do not touch grinding and cutting discs before they

have cooled down. The discs can become very hot while

working.

LED

Capacity

Continuous lighting 3 x green

2/3

Continuous lighting 2 x green

1/3

Continuous lighting 1 x green

<1/3

Flashing light 1 x green

Reserve

OBJ_BUCH-1102-005.book Page 20 Thursday, January 10, 2013 11:03 AM