York MILLENNIUM ND600 User Manual

Technical guide, Description

TECHNICAL GUIDE

R-410A

SPLIT-SYSTEM

AIR HANDLERS

MILLENNIUM™

ND360, 480 & 600

30 - 50 Ton

60 Hertz

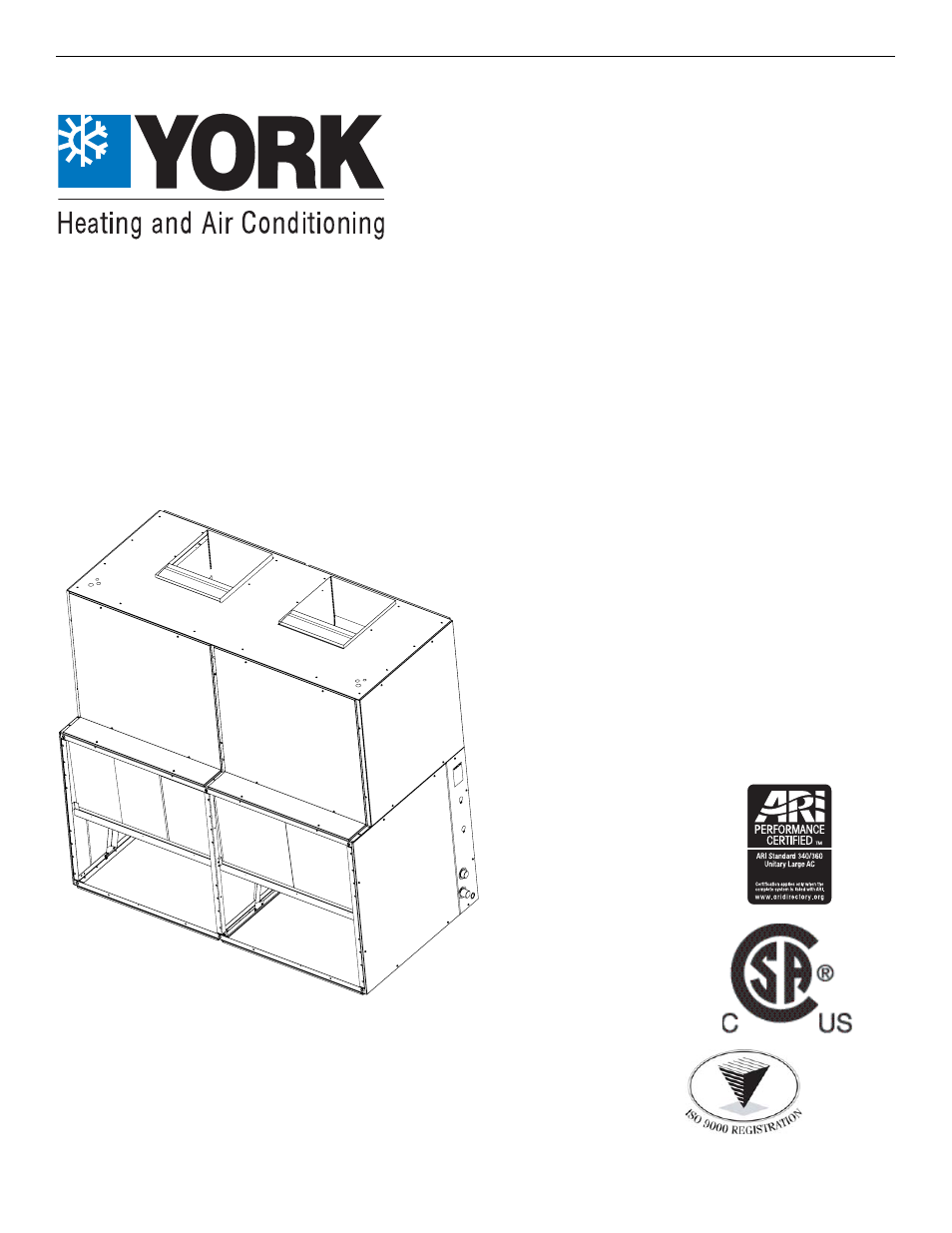

ND600 AIRHANDLER & M1CZ600 EVAPORATOR SECTION

®

628767-YTG-C-0910

ISO 9001

Certified Quality

Management System

Description

These air handling units are completely assembled units,

including a well-insulated cabinet, a DX cooling coil with copper

tubing, aluminum fins, expansion valve(s), distributor(s), 2”

throwaway filters, a centrifugal blower, a blower motor, an

adjustable belt drive, a blower motor contactor and a small

holding charge of nitrogen.

Units are shipped in the vertical position ready for field

installation, but can be easily converted to horizontal position.

This manual is related to the following products:

Table of contents

Document Outline

- Description

- Table of Contents

- Description 1

- Table of Contents 2

- Nomenclature 3

- Air Handling Unit Features and Benefits 4

- Guide Specifications 5

- Physical Data 7

- Unit Limitations 8

- Cooling and Heating Ratings 8

- Capacity Performance 9

- Air Handling Unit and Hot Water Coil Accessory Heating Capacity 15

- Air Handling Unit and Steam Coil Accessory Heating Capacity 16

- Fan Performance 17

- Sound Performance 19

- Electrical Data 20

- Typical Wiring Diagrams 21

- Weights And Dimensions 22

- Unit Mounting 32

- Typical Field Wiring Diagrams 36

- Nomenclature

- Air Handling Unit Features and Benefits

- Guide Specifications

- MILLENNIUM™

- Split System Air-Cooled Air Handler Models: NC300 and ND360, 480 and 600

- General

- Description

- Unit Cabinet

- a. A steel angle frame to provide the rigid support required for shipping, rigging and years of dependable operation.

- b. Exterior panels of 18 gauge steel, finished with baked enamel to provide a long-lasting quality appearance.

- c. Removable panels to provide easy access to the internal components for maintenance and service.

- d. A filter rack with 1" or 2" filters.

- Indoor (Evaporator) Fan Assembly

- Refrigerant Components

- a. Evaporator coils shall have aluminum plate fins mechanically bonded to seamless internally enhanced copper tubes with all joints brazed.

- b. Evaporator coil shall be of the direct expansion, draw through design.

- a. Include factory-mounted distributors, adjustable thermal expansion valves and solenoid valves for both capacity reduction and refrigerant pump out on start- up.

- b. Include factory installed auxiliary side connectors for the addition of field installed hot gas bypass.

- c. Shall include filter/strainer to eliminate any foreign matter.

- Controls

- The Installer Shall:

- Unit Operating Characteristics

- Electrical Requirements

- Each Unit Shall Include The Following Accessories:

- Physical Data

- Unit Limitations

- Cooling and Heating Ratings

- Capacity Performance

- Air Handling Unit and Hot Water Coil Accessory Heating Capacity

- Air Handling Unit and Steam Coil Accessory Heating Capacity

- Fan Performance

- Sound Performance

- Electrical Data

- Typical Wiring Diagrams

- Weights And Dimensions

- Corner Weights & Center of Gravity ND360, 480 & 600 Unit

- Unit Dimensions ND360

- Unit Dimensions ND360 (Continued)

- Unit Dimensions ND480

- Unit Dimensions ND480 (Continued)

- Unit Dimensions ND600

- Unit Dimensions M1CZ600 Evaporator Section

- Unit Dimensions ND600 Airhandler & M1CZ600 Evaporator Coil

- Dimensions Hot Water Coil

- Dimensions Steam Coil

- Dimensions Base Section

- Unit Mounting

- Typical Field Wiring Diagrams