Adjustments – RIDGID SP6263 User Manual

Page 26

26

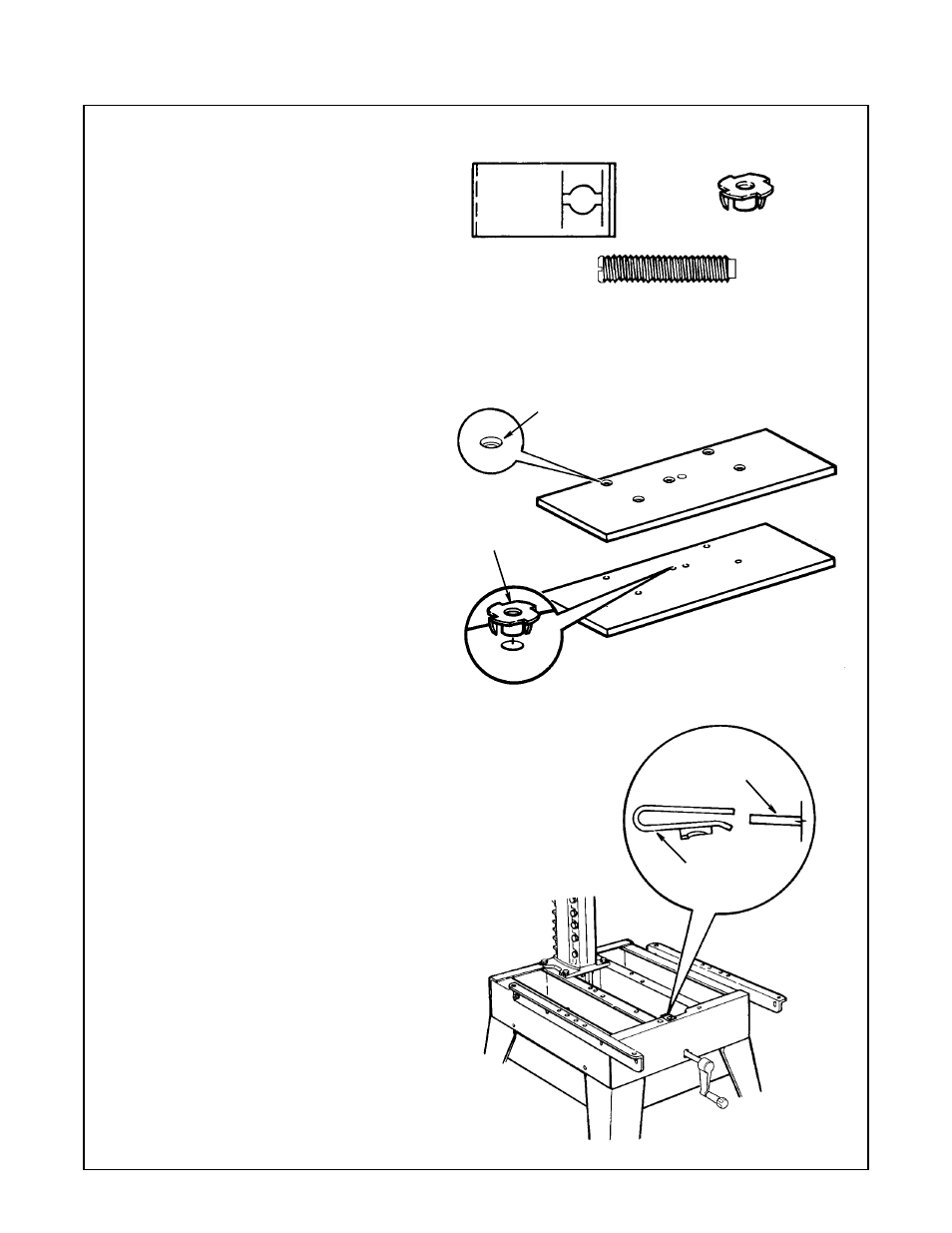

lnstalling Front Table

1. Set out:

- front table

- tee nut

- 1/4" U-clip

- 1/4" diam. x 1" long cup point set

screw

- four 1/4" diam x 1" long pan head

screws

- 1/4" diam. x 1-3/4" long pan head

screw

- five 17/64" I.D. x 5/8" O.D. flat wash-

ers

- four 1/4" lock washers

- four 1/4" diam. hex nuts.

2. Identify top and bottom of front table: top

has counterbored holes. Place table bottom

side up on solid surface. Hammer tee nut

into leveling hole. (This hole is not

counter-bored from the top).

3. Snap U-clip onto front edge of base so

hole lines up with hole just to the left of cen-

ter notch.

4. Place table, top side up, on saw so center

counterbored hole lines up with hole in U-clip.

Note:

Table will extend over front edge of saw frame.

T-Nut

Bottom

Top

Five Counterbored Holes

U-Clip

Channel

Adjustments

- R843 (20 pages)

- 932VS (37 pages)

- R3210-1 (26 pages)

- CM1450 (16 pages)

- R883 (4 pages)

- R3203-1 (24 pages)

- MS1290LZA (40 pages)

- AC99401 (16 pages)

- MS1065LZA (32 pages)

- R3210 (24 pages)

- TS3650 (76 pages)

- 932/932VS (2 pages)

- BS1400 (32 pages)

- R845 (24 pages)

- MS1290LZ1 (40 pages)

- AC9930 (12 pages)

- R8452 (24 pages)

- MaxSelect R885 (26 pages)

- AC99402 (16 pages)

- TS2400LS (39 pages)

- 122XL (39 pages)

- TS 2400 (68 pages)

- MS1250LZ1 (34 pages)

- MS1250LZA (36 pages)

- BS14002 (36 pages)

- AC1030 (6 pages)

- R4121 (25 pages)

- TS3660 (56 pages)

- Table Saw (68 pages)

- R4516 (40 pages)

- MS1065LZ (30 pages)

- R3120 (20 pages)

- Dry Cut Saw (36 pages)

- AC9940 (16 pages)

- MS1290LZ (40 pages)

- R3200 (2 pages)

- R855 (24 pages)

- MS1250LZ (36 pages)

- R3202 (22 pages)

- AC9944 (8 pages)

- 530-2 Reciprocating Saw (21 pages)

- HC-300 (320 pages)