Raypak 302B-902B User Manual

Page 48

48

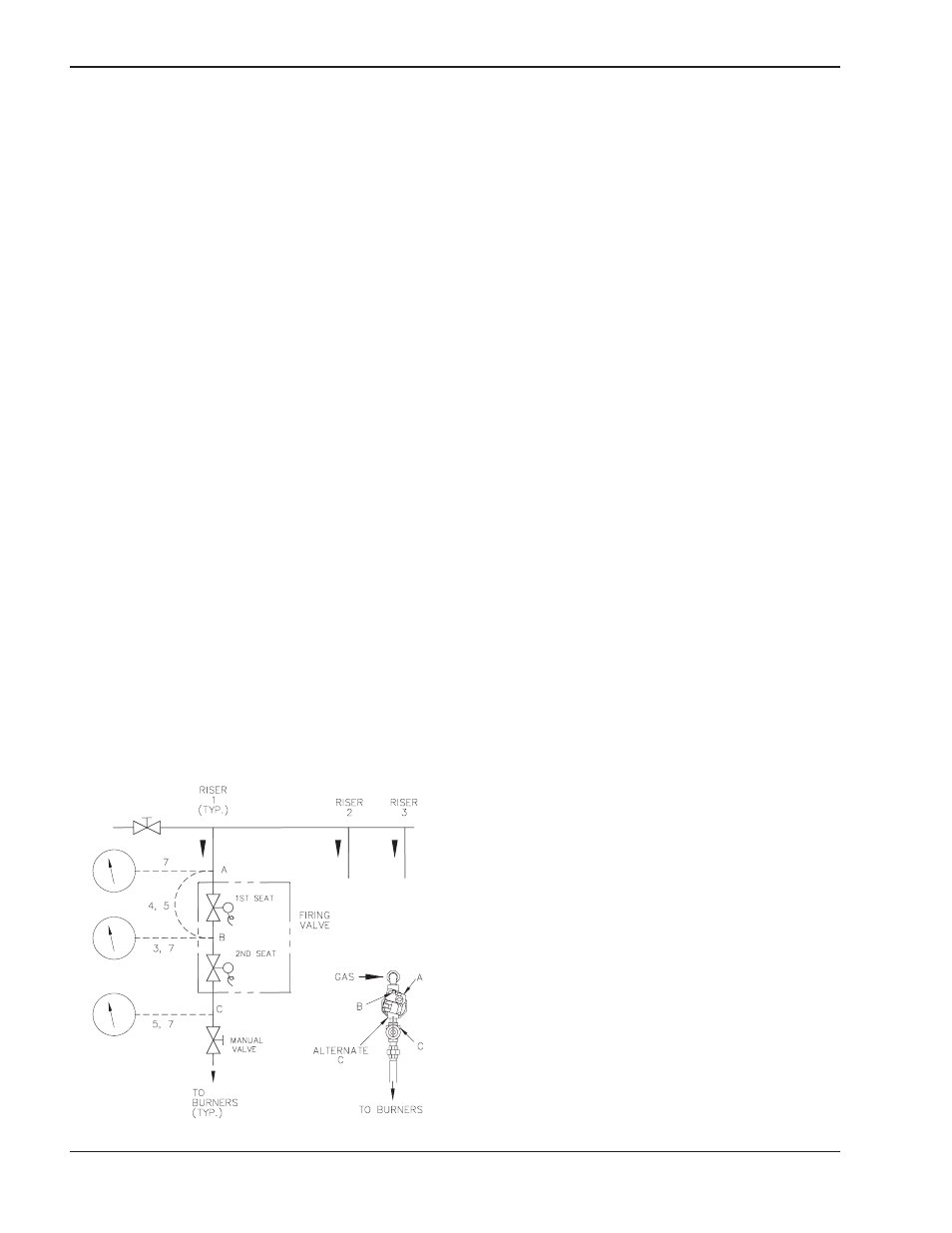

1. Manually close the downstream leak test valve.

2. Open test point A and connect a manometer to it.

Verify that there is gas pressure and that it is with-

in the proper range (NOTE: must not exceed 14.0

in. WC).

3. Open test point B and connect a rubber tube to it.

Connect the other end of the tube to a manometer

and look for a build-up of pressure. Increasing

pressure indicates a leaking gas valve.

4. Next, close the upstream manual gas valve and

remove the manometer from test point A and from

test point B. Connect a rubber tube from test point

A to test point B and open the upstream manual

gas valve. Make sure that test points A & B have

been opened so as to allow gas to flow. This will

bring pressure to the second valve seat.

5. Open test point C and connect a second rubber

tube to it. Connect the other end of the tube to a

manometer and look for a build-up of pressure. In-

creasing pressure indicates a leaking gas valve.

6. Remove rubber tube and manometers. Close

each test point valve as the tubes are removed.

7. Connect a manometer to each test point (one at a

time) and look for a build-up of pressure. If a build-

up of pressure is detected, check each test point

valve to see if it is tightly closed. If leak persists,

replace test point valve(s).

8. After no leakage has been verified at all valve

seats and test valves, open downstream leak tests

valve and restore electrical power to heater.

Fig. 42: Leak Test

This completes leak testing for a single Hi Delta mani-

fold riser. Repeat steps 1-8 for each riser.

Post Start-Up Check

Check off steps as completed:

1. Verify that the heater and heat distribution units or

storage tank are filled with water.

2. Confirm that the automatic air vent (if used) was

opened two full turns during the venting proce-

dure.

3. Verify that air has been purged from the system.

4. Verify that air has been purged from the gas pip-

ing, and that the piping has been checked for

leaks.

5. Confirm that the proper start-up procedures were

followed.

6. Inspect burner to verify flame.

7. Test safety controls: If heater is equipped with a

low water cut-off or additional safety controls, test

for operation as outlined by manufacturer. Burner

should be operating and should go off when con-

trols are tested. When safety devices are restored,

burners should re-ignite after pre-purge time

delay.

8. Test limit control: While burner is operating, move

indicator on high limit control below actual water

temperature. Burner should go off while blower

and circulator continue to operate. Raise setting

on limit control above water temperature and burn-

er should re-ignite after pre-purge time delay.

9. Test ignition system safety device:

a. Turn on manual gas valve. Turn power on.

b. Set thermostat to call for heat.

c. When the heater is in operation, pull cap off of

tee in air switch hose. The burner should go

off immediately.

d. Wait 5 minutes.

e. Reattach cap on tee. Burner should re-ignite

after pre-purge time delay.