Raypak 302B-902B User Manual

Page 35

35

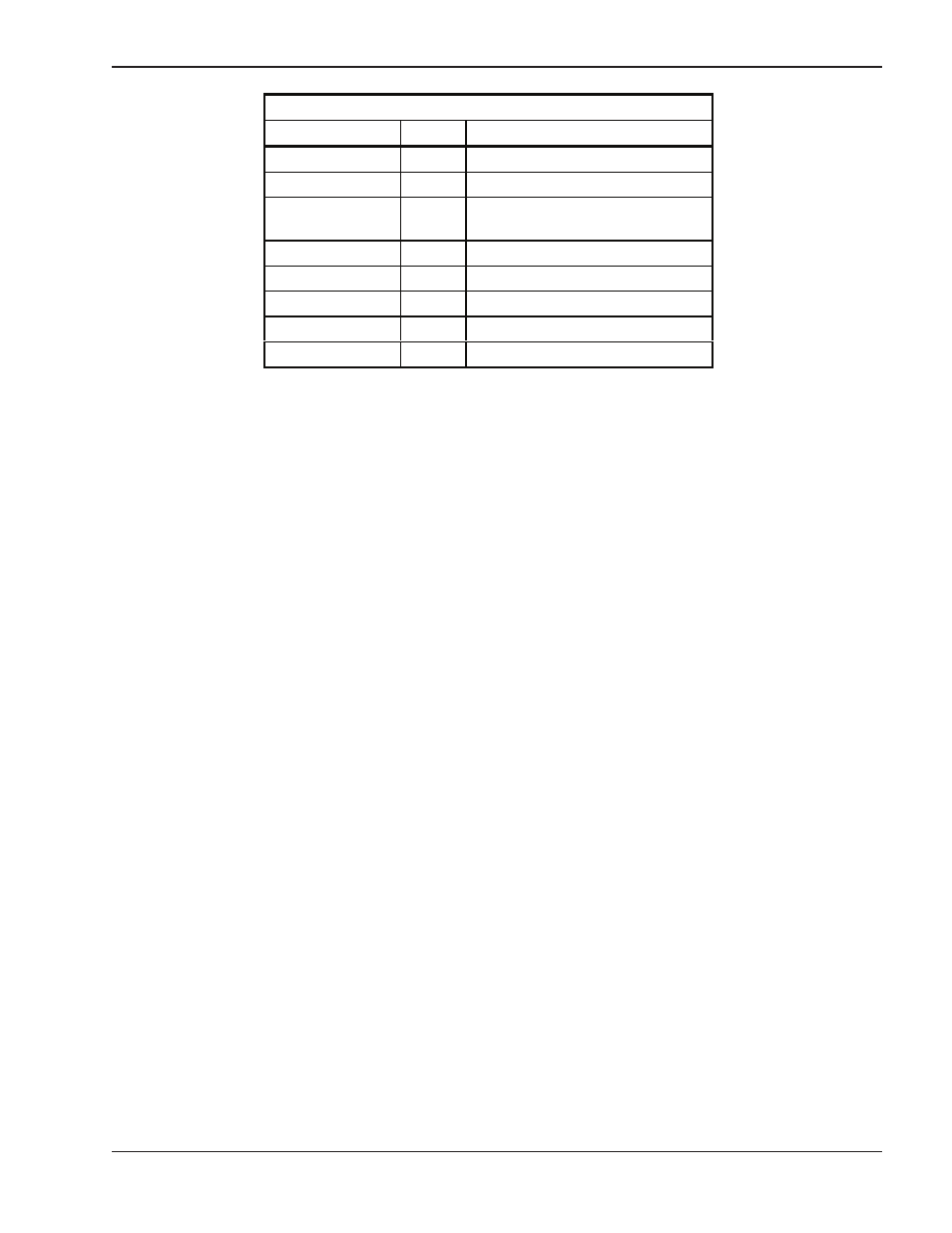

External Lights

Light

Color

Indication

Power

Blue

Main power is on

Call For Heat

Yellow

Thermostat is closed

Safety

Red

One or more safeties is inopera-

tive

Ignition

Red

Ignition module is inoperative

Flow

Green

Flow is present

Blower 1

Green

Blower 1 is on

Stage 1

Green

Stage 1 is on

Stage 2

Green

Stage 2 is on

I

Table P: Status LED Indicators

24. Power is also sent from pin 2 of the stage 1 con-

nection to pin P1-3 of the universal diagnostic

board.

25. Power is now sent to terminal TP4 of the

Economaster to energize the relay and close the

contacts.

26. Power is waiting at the common terminal of the

flow switch waiting for closure and sufficient water

flow.

27. The heater pump is energized upon relay closure

of the Economaster.

28. Upon sufficient flow from the heater pump, the

flow switch contacts will close.

29. If there is insufficient flow and the flow switch does

not close, a 24 VAC signal is sent to the Universal

Diagnostics Board to indicate the fault.

30. The flow light is energized; located on the front

status panel.

31. A 24 VAC signal is also sent to the “TH” terminal

located on the ignition module.

32. Once the 24 VAC “TH” signal is received at the

ignition module, the internal contacts between F1

and F2 close sending a 120 VAC signal to the 120

VAC pilot duty terminals, located at J14 on the cir-

cuit board.

33. The 120 VAC signal continues to the coil of the

blower relay K-3 (N.O.).

34. The 120 VAC signal continues to the 120 VAC

safety terminals located at J13 on the circuit

board.

35. When the coil on relay K-3 is powered, the N.O.

relay contacts close and energizes the blower

from the J8 connections on the CPW board.

36. After proper air pressure is received in the air

plenum, the air pressure switch will close.

37. If there is insufficient air pressure and the air pres-

sure switch does not close, a 24 VAC signal is sent

to the Universal Diagnostics Board to indicate the

fault.

38. A 24 VAC signal is now sent to the blower LED on

the status board.

39. Power is applied to the optional equipment inter-

lock connection J9 (normally jumpered).

40. The 24 VAC signal is then sent to the 24 VAC safe-

ty connector.

41. 24 VAC is now sent to the pressure switch (P.S.)

terminal on the ignition module.

42. Once the pressure switch signal is received at the

ignition module, the heater performs a 15-second

pre-purge and then the hot surface igniter is ener-

gized by a 120 VAC signal from S-1 on the ignition

module for approximately 30 seconds. (The hot

surface igniter must draw greater than 3.1 amps

while being energized or ignition lockout will occur

after three tries.)

43. Once the ignition module determines that the hot

surface igniter has heated up and operating prop-