Hydronic heating – Raypak 302B-902B User Manual

Page 16

16

Failure to exceed 105ºF (41ºC) within 7 minutes may

result in the premature failure of the hot surface ignit-

er, remote flame sensor, burners and heat exchanger.

It can cause operational problems, bad combustion,

sooting, flue gas spillage and reduced service life of

the vent system. The bypass allows part of the heater

discharge water to be mixed with the cooler heater

return water to increase the heater inlet temperature

above 105ºF (41ºC). This precautionary measure

should prevent the products of combustion from con-

densing in most installations. Warranty claims will be

denied when condensation occurs.

Cold water operation issues are applicable to both

cold water start and cold water run applications. Cold

water operation for 7 minutes or less on start-up is

acceptable. Where cold water starts will last longer

than 7 minutes or where cold water operation is con-

tinuous, provisions must be made to mix higher

temperature outlet water with the colder inlet water

and thereby raise the inlet temperature to at least

105ºF (41ºC) within the 7-minute time limit.

Cold Water Starts

Frequent (more than once a week) cold water starts,

wherein the inlet water temperature remains below

105ºF (41ºC) for more than 7 minutes, must have cold

water start protection. Known protection methods con-

sist of mixing heated outlet water with the inlet water

with a bypass to raise the inlet to 105ºF (41ºC) or high-

er. Once the system is heated up and has return water

temperatures of 105ºF (41ºC) or higher, the mixing of

outlet water with inlet water is no longer needed and

the bypass can be shut off. If the bypass is not shut off

as the system heats up, the outlet temperature may

continue to climb and actuate the high limit, thereby

Cold Water Run

Cold water run differs from cold water start in that the

system water entering the heater remains below 105ºF

(41ºC) continuously. Typically, this is the case in swim-

ming pool heating and water source heat pump

applications as well as some others. If the system

water is kept in a narrow temperature range, a perma-

nent manual bypass can be employed and manually

adjusted to achieve an inlet temperature of 105ºF

(41ºC) or higher. An injector pump arrangement may

also be utilized to keep the heater loop at or above

105ºF (41ºC). An injector pump approach has the

added value of being able to adjust to changes in the

system water coming back to the heater take-off.

Temperature & Pressure Gauge

The temperature and pressure gauge is factory-

mounted in the in/out header.

Hydronic Heating

Pump Selection

In order to ensure proper performance of your heater

system, you must install a correctly sized pump. Ray-

pak recommends using a 20°F ∆T as design ∆T. (∆T is

the temperature difference between the inlet and out-

let water when the heater is firing at full rate). If a ∆T

of larger than 20°F is necessary, see Table H and

Table I for flow rate requirements.

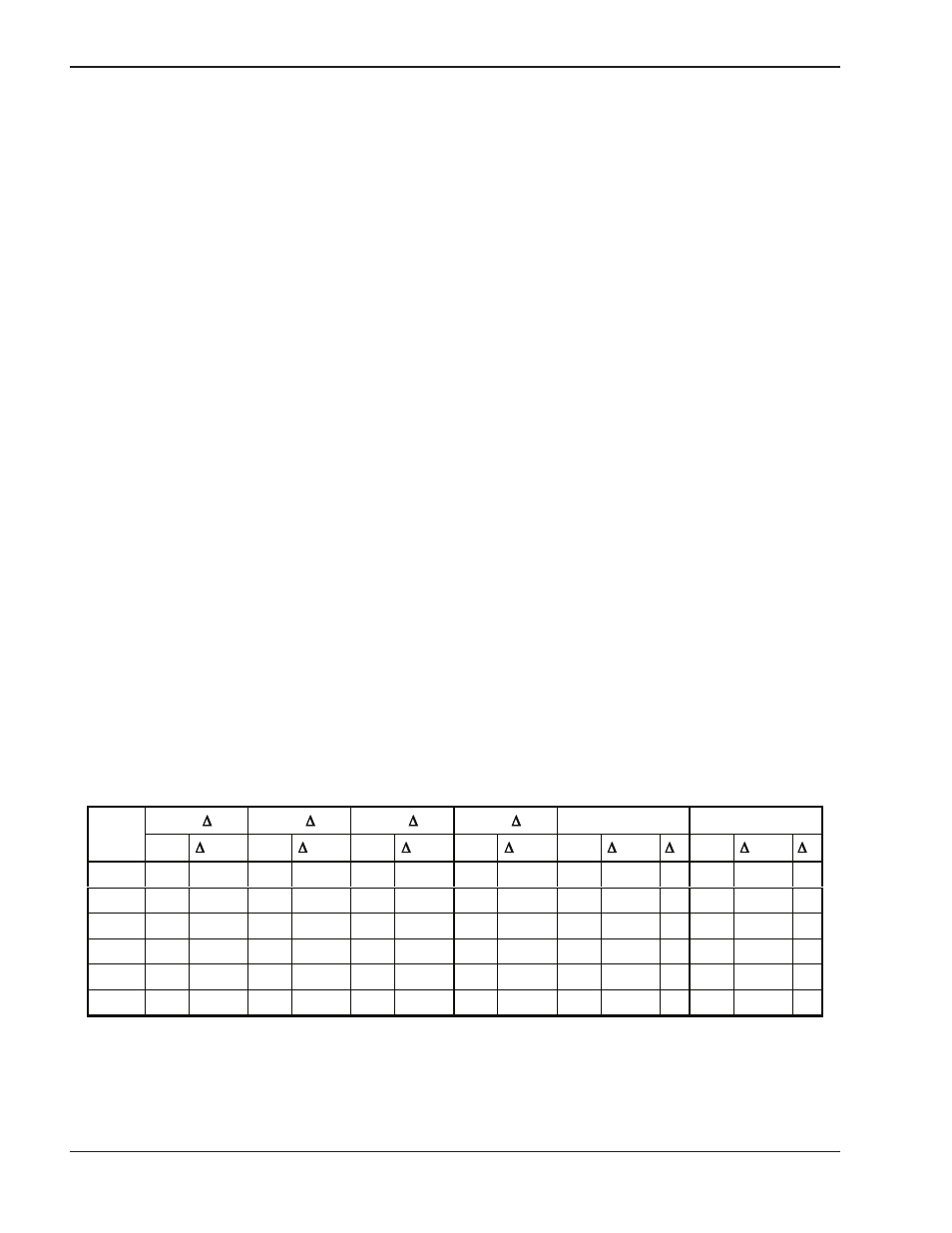

Table H: Heater Rates of Flow and Pressure Drops

10°F T

20°F T

30°F T

40°F T

Min. Flow

Max Flow

Model

No.

gpm

P (ft) gpm

P (ft) gpm

P (ft) gpm

P (ft) gpm

P (ft)

T gpm

P (ft)

T

302B

50

3.1

25

0.8

N/A

N/A

N/A

N/A

20

0.5

25

90

9.8

6

402B

67

5.5

34

1.4

22

0.6

N/A

N/A

20

0.5

34

90

10.0

7

502B

84

9.1

42

2.3

28

1.1

21

0.6

21

0.6

40

90

10.4

9

652B

N/A

N/A

55

4.1

36

1.8

27

1.1

27

1.1

40

90

10.8

12

752B

N/A

N/A

63

5.7

42

2.6

32

1.5

32

1.5

40

90

11.3

14

902B

N/A

N/A

76

8.3

50

3.8

38

2.2

38

2.2

40

90

11.7

17

Notes:

1. Basis for minimum flow is 20 gpm or 40°F ∆T. Basis for maximum flow is 90 gpm. Flow switch will not operate if flow is less

than 20 gpm.

2. Rear-mounted pumps may provide higher flow rates on smaller models than the system requirements.

shutting down the heater. Thus an automatic valve

system, such as a three-way proportional valve or a

modulating two-way valve to control the bypass,

should be utilized.