Troubleshooting & repair, Diode module removal and replacement (continued) – Lincoln Electric MULTI-WELD SVM151-A User Manual

Page 99

TROUBLESHOOTING & REPAIR

F-59

F-59

MULTI-WELD 350

SPRING WASHER

PLAIN WASHER

2 TO 3

TURNS EACH

FINGER TIGHT

5.0-10 IN-LBS.

5.0-10 IN-LBS.

12-18 IN-LBS.

30-40 IN-LBS.

1

2

3

4

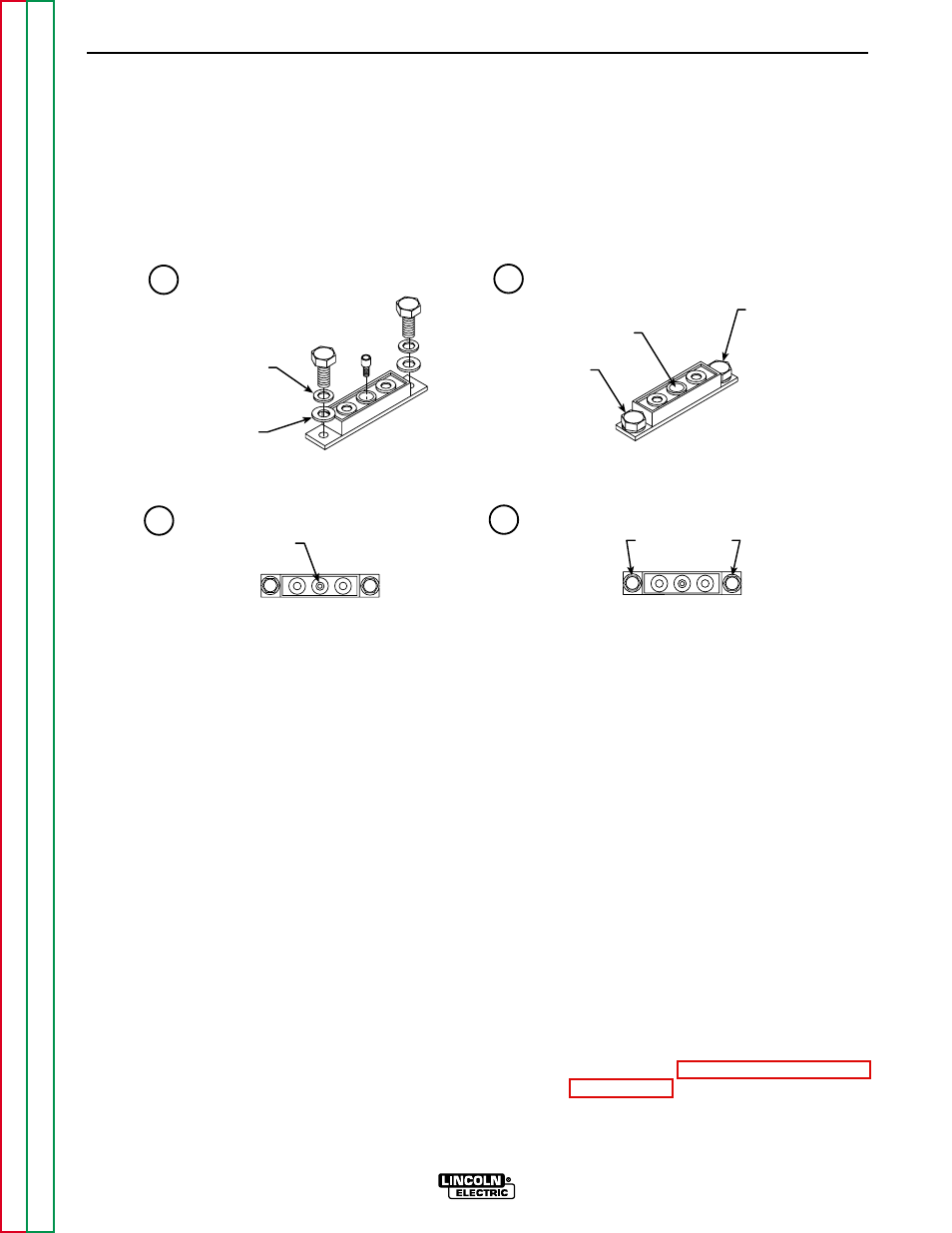

FIGURE F.16 – DIODE MODULE TIGHTENING SEQUENCE

DIODE MODULE REMOVAL AND REPLACEMENT(CONTINUED)

Refer to Figure F.16.

4.

Place a spring washer then a flat washer

over each outer mounting screw and insert

them into the holes. Insert the allen head

screw into the center hole. Tighten all three

screws 2 – 3 turns each, finger-tight only.

(1)

5.

Using the torque wrench and 7/16" socket,

tighten the outer screws to between 5.0 and

10 in-lbs. (2)

6.

Using the torque wrench and 9/64" allen

head socket, tighten the center screw

between 12 and 18 in-lbs. (3)

7.

Now tighten the two outer screws between

30 and 40 in-lbs. (4)

8.

Place the negative capacitor strap over the

diode module and align the mounting holes.

Place a lock washer and two flat washers

over each 7/16" screw and insert them into

the holes. Using the torque wrench and

7/16" socket, tighten each screw between

30 and 40 in-lbs.

9. Install the 7/16" bolt, lock washer, flat

washer, heavy lead and negative strap to

the negative terminal on the capacitor.

Tighten the bolt to 50-60 in-lbs.

10. Remove the wooden blocking and careful-

ly lower the tunnel assembly onto the

machine base. Support the tunnel assem-

bly and turn the machine onto its side.

11. With the 3/8" wrench, install the four

screws that hold the tunnel assembly to the

machine base. Turn the machine back

upright.

12. Perform the Case Cover Assembly

Replacement procedure.