And b.1. ), Figure b.1 ), paralleling (cc mode only) and, Operation – Lincoln Electric MULTI-WELD SVM151-A User Manual

Page 15: Product description

PRODUCT DESCRIPTION

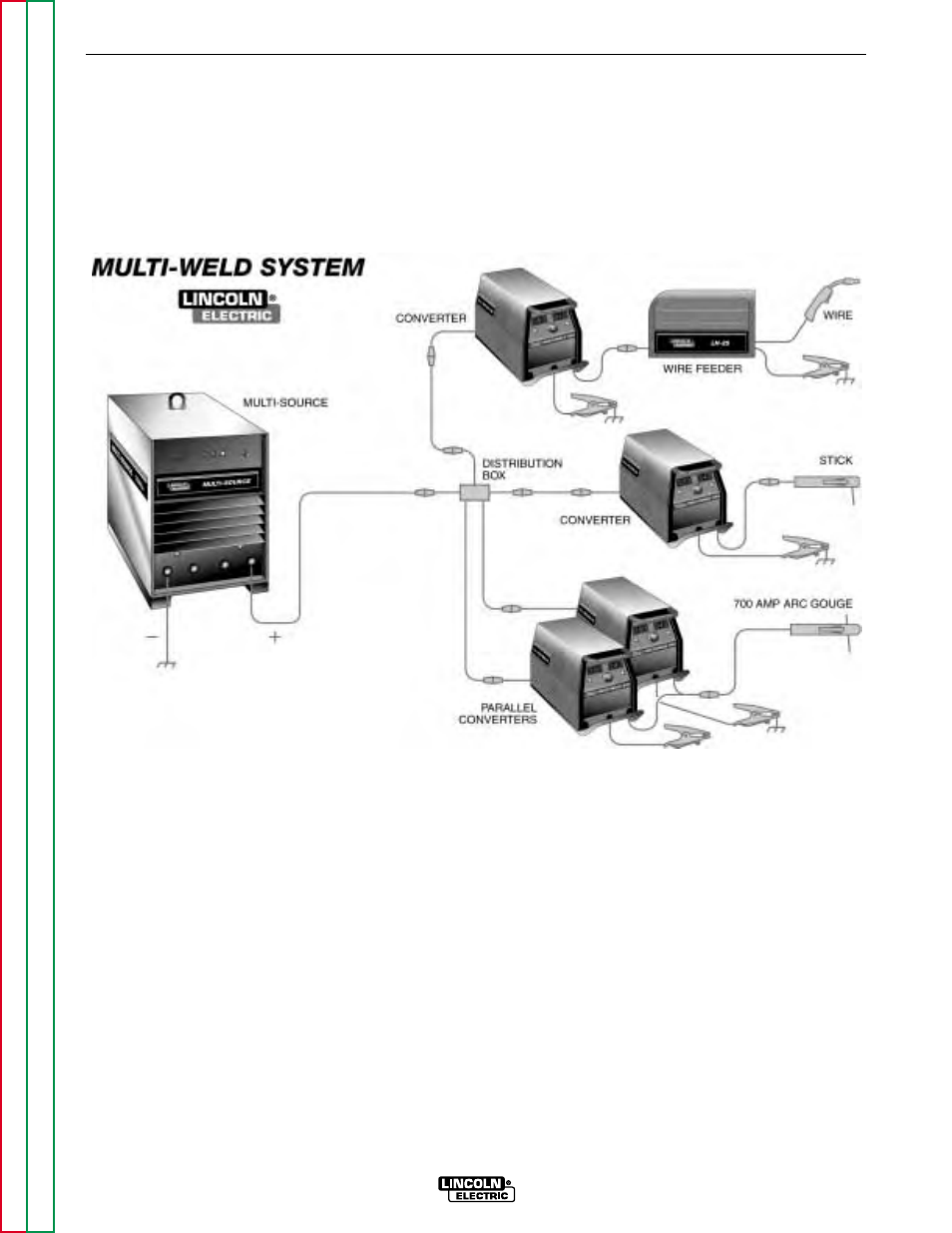

The Multi-Weld 350 Arc Converter (K1735-1) is part of

a Multi-Weld system, ideally suited for construction site

welding. It uses a single DC power source as the

only input supply and provides independent, full-range

control of up to 350A continuous with each Converter

arc for + polarity stick and wire processes, as well as

for arc-air gouging. (See Figure B.1.)

The Multi-Weld 350 is a DC to DC Converter that con-

verts higher voltage/lower current input power to lower

voltage/higher current output power with over 90% effi-

ciency.

For example, a single 600A continuous rated 70-80V

power source could supply up to five Multi-Weld 350

converters, each wire welding at 300 amps, or about

ten converters for stick welding at 150 amps with 26-

29V at the arcs.

The Multi-Weld 350 Arc Converter is a single “world”

model built to IEC and CSA standards and meeting the

specific needs inherent to construction site welding:

Versatile

• Constant Current (CC) mode for stick and gouging.

Includes Hot Start and Arc Force controls to optimize

CC performance, and can be paralleled for higher

capacity welding and arc gouging.

• Constant Voltage (CV) mode for positive polarity

cored and solid wire welding with arc-powered feed-

ers (such as the LN-25).

Portable

• The Multi-Weld 350 can be moved quickly. The light-

weight Converter is easy to carry or pull and is small

enough to fit through a 15" (38 cm) diameter or 12" x

16" (31x 41 cm) elliptical man-hole.

• The Converter is powered by the welding cable from

the DC power source, without the safety hazard of

high AC input supply voltages.

• Welding controls are near the arc without long con-

trol cables, and a receptacle is provided for an

optional remote for even closer user output control.

B-3

B-3

OPERATION

MULTI-WELD 350

FIGURE B.1 – MULTI-WELD SYSTEM