Theory of operation, General description – Lincoln Electric MULTI-WELD SVM151-A User Manual

Page 32

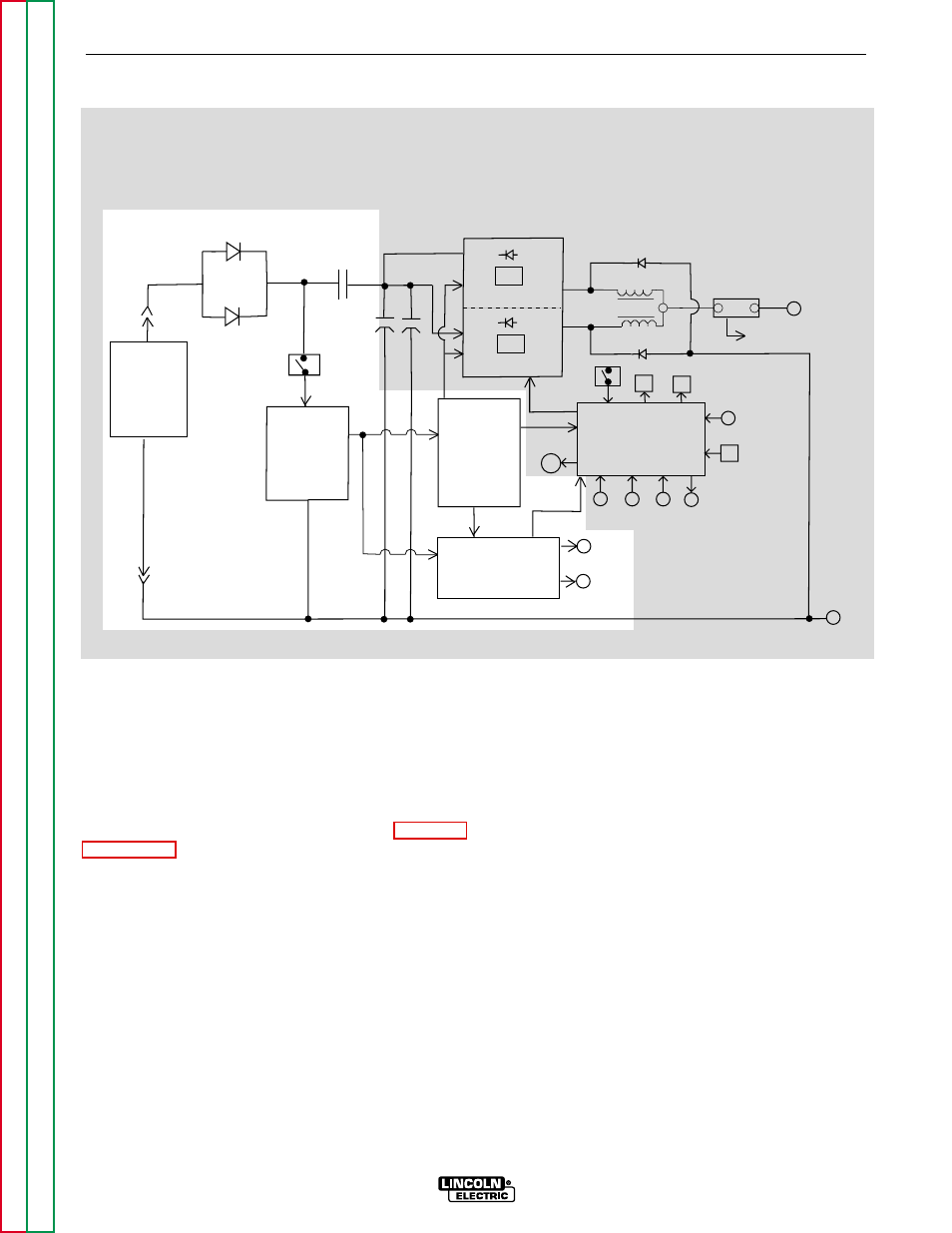

GENERAL DESCRIPTION

The MULTI-WELD 350 Converter uses a single DC

input power source to provide up to 350 continuous

amps for positive polarity stick, wire processes, and

arc-air gouging. The machine converts higher volt-

age/lower current DC input power to lower

voltage/higher current DC output power with over 90%

efficiency. This DC output is controlled by Chopper

Technology to produce DC current for multi-purpose

welding applications.

INPUT POWER SOURCE,

CONTACTOR AND DC BUSS

POWER SUPPLY BOARD

The Multi-Weld 350 receives DC input power from an

80 VDC buss Multi-Source (recommended), although

other external DC sources such as the Lincoln Electric

DC-1000, DC-655, or DC-600 can be used if they pro-

duce 50 VDC or above.

The +50 VDC supply voltage is applied to the input

contactor via two large input diodes. The input contac-

tor establishes the electrical connection between the

Multi-Weld 350 and the power source when the

ON/OFF MODE switch is activated in either the con-

stant current (CC-stick) mode or the constant voltage

(CV-wire) mode.

A 40 VDC Buss Power Supply Board supplies 40 VDC

power to the Analog Control Power Supply Board,

which in turn feeds regulated voltages to a Weld

Control Board and 15 VDC to the Peripheral Board.

The Peripheral Board powers the input contactor coil

and the input indicator light on the front panel. The 40

VDC is also supplied to the Peripheral Board and is

passed on to the Weld Control Board.

E-2

E-2

THEORY OF OPERATION

MULTI-WELD 350

CHOKE

IGBT

IGBT

SHUNT

WORK

TO ELECTRODE

CABLE

+

ANALOG

CONTROL

POWER

SUPPLY

BOARD

WELD

CONTROL

BOARD

ARC

FORCE

CONTROL

OUTPUT

CONTROL

HOT

START

DC

BUS

POWER

SUPPLY

BOARD

FAN

+

DC

POWER

SOURCE

(EXTERNAL)

_

REMOTE

RECEPTACLE

INPUT

DIODES

INPUT

CONTACTOR

MULTI-WELD 350 BLOCK LOGIC DIAGRAM

CC SLOPE

(STICK/GOUGE or PIPE)

PERIPHERAL

BOARD

INPUT

INDICATOR

LIGHT

ON/OFF

MODE

SWITCH

(1/2)

CR1

CHOPPER MODULE

CHOPPER MODULE

ON/OFF

MODE

SWITCH

(1/2)

VOLTS

AMPS

THERMAL

LIGHT

FREEWHEELING DIODE

FREEWHEELING DIODE

REGULATED

VOLTAGES

CR1

COIL

15 VDC

CURRENT FEEDBACK

TO WELD CONTROL BOARD

20

VDC

x 2

-

INPUT

CAPACITORS

40

VDC

LEFT AND RIGHT

CHOPPER MODULES

GATE

SIGNALS

40 VDC

FIGURE E.2 – INPUT POWER SOURCE, CONTACTOR AND DC BUSS POWER SUPPLY BOARD

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.