Make-up air – Speed Queen Drying Tumblers SCB50EG User Manual

Page 34

32

M412616

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Do not

install elbows with a radius less than shown in table

below. Exhaust ducts must be assembled so interior

surfaces are smooth to reduce accumulation of lint.

Do not use sheet metal screws to join vent sections.

Improperly sized or assembled ductwork causes

excess back pressure which results in slow drying,

lint collecting in duct, lint blowing back into room, and

increased fire hazard.

Exhaust ducts shall be constructed of sheet metal

or other noncombustible material. Such ducts

must be equivalent in strength and corrosion

resistance to ducts made of galvanized sheet

steel not less than 0.0195 inches (0.495 mm)

thick.

Where exhaust duct pierces a combustible wall or

ceiling, an opening having a diameter of 4 inches

(10.2 cm) larger than diameter of exhaust duct shall

be provided, with duct centered in opening. When

ducts pass through walls, ceilings, floors or partitions,

space around the duct shall be sealed with non-

combustible material. See

Figures 1, 2 and 3.

•••••

Individual Venting

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to

outdoors. At no point may cross area of

installed venting be less than cross area of

exhaust thimble of tumbler.

Maximum allowable length of venting is 14 feet

(4.3 m) and two 90° elbows or equivalent. If

equivalent length of a duct required for an

installation exceeds maximum allowable

equivalent length, diameter of a round duct must

be increased by 10% for each additional 20 feet

(6.1 m). Cross section area of a rectangular duct

must be increased by 20% for each additional 20

feet (6.1 m). Table below shows how to determine

equivalent venting:

Example: A 6-inch (15.2 cm) diameter duct’s

equivalent length of 14 feet (4.3 m) of duct

and two 90° elbows is:

Equivalent length

= 14 feet (4.3 m) + (2) 90° elbows

= 14 feet (4.3 m) + 7 feet (2.1 m) + 7 feet (2.1 m)

= 28 feet (8.5 m)

With tumbler in operation, airflow at any point in

duct must be at least 1200 feet (366 m) per

minute to insure that lint remains airborne.

•••••

Collector Venting

While it is preferable to exhaust tumblers

individually to outdoors, a main collector duct may

be used if it is sized according to

Figure 3.

NOTE: This illustration indicates minimum

diameters, and should be increased if collector

length exceeds 20 feet (6.1 m).

Collector duct may be rectangular in cross

section, as long as area is not reduced. Provisions

should be made for lint removal and cleaning of

collector duct.

Collector duct must be tapered, as shown in

Figure 3. Individual tumbler ducts must enter the

collector duct at a 45° angle in direction of air flow.

Never connect a tumbler duct at a 90° angle to

collector duct. Doing so will cause excessive

back pressure, resulting in poor performance.

Never connect two tumbler exhaust ducts

directly across from each other at point of

entry to collector duct.

Collector system must be designed so static back

pressure measured 12 inches (30.5 cm) from

exhaust thimble does not exceed maximum

allowable pressure specified on installation sticker

on rear of tumbler. Measured with all tumblers

running that are vented into collector.

MAKE-UP AIR

A tumbler is forced air exhausted and requires

provisions for make-up air to replace the air

exhausted by tumbler.

Manufacturer’s recommended make-up air opening

for each tumbler is 144 square inches (928 sq. cm)

for 30 and 50 pound tumblers and 195 square inches

(1258 sq. cm) for 75 pound tumblers. At a minimum,

tumblers must have at least 1 in

2

(2.54 cm

2

) of

opening for every 1000 BTU/hr (252 Kcal/hr) of

input rating for proper combustion.

Example: A tumbler with a rated input of 120,000

BTU/hr (30,240 Kcal) requires 120 in

2

(774 cm

2

) of free opening.

Protective louvers in opening to outdoors can reduce

air movement by approximately 40%. Opening must

compensate for area taken up by louvers.

Make-up air openings for a room containing

tumbler(s) and/or gas fired hot water heater or other

gravity vented appliances must be increased

sufficiently to prevent downdrafts in any vents when

all tumblers are in operation. Do not locate gravity

vented appliances between tumbler(s) and make-up

air openings. If it is necessary to duct make-up air to

tumbler(s), increase area of work by 25% to

compensate for any restriction in air movement.

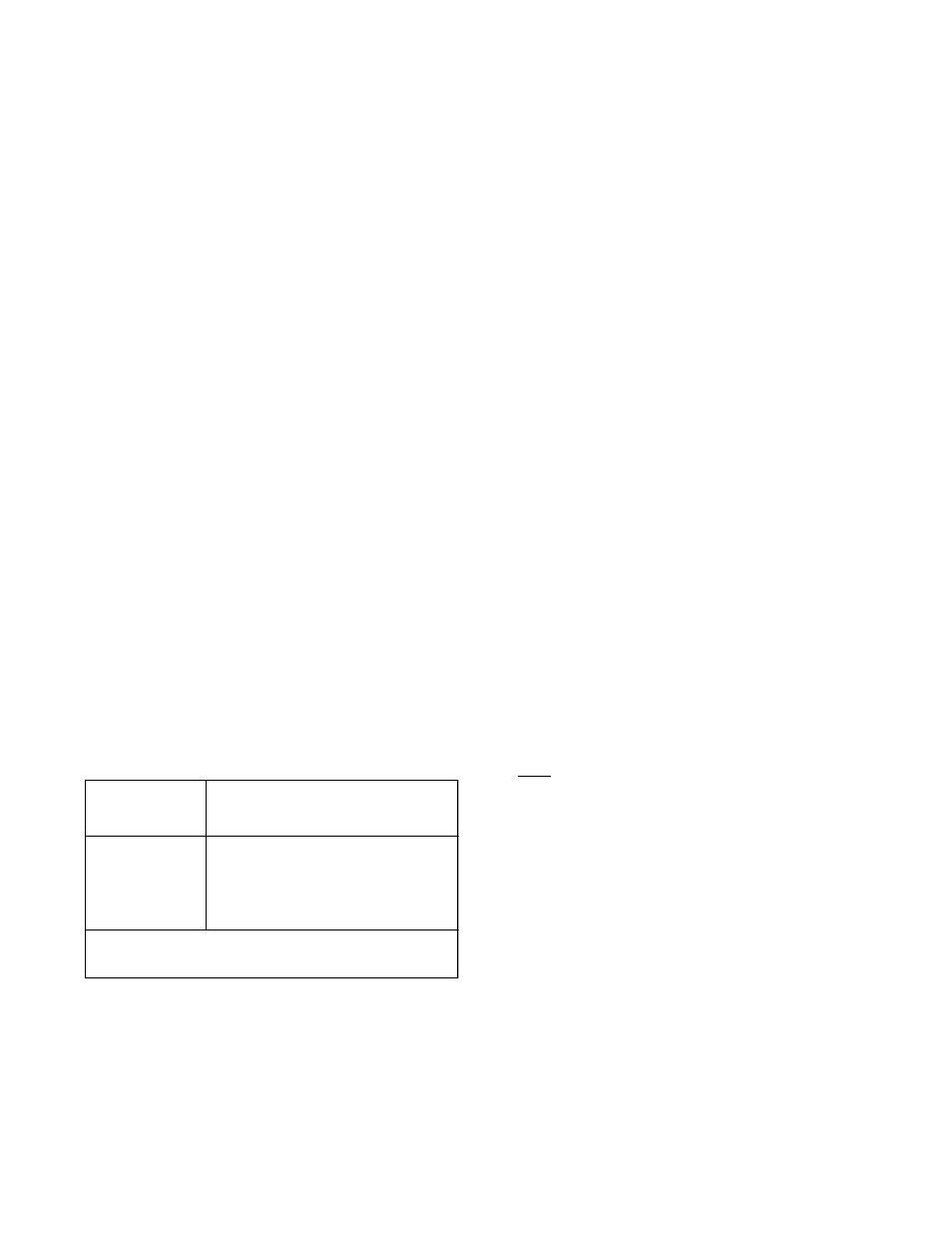

DUCT

DIAMETER

EQUIVALENT LENGTH OF

STRAIGHT DUCT

6" (15.2 cm)

8" (20.3 cm)

10" (25.4 cm)

12" (30.5 cm)

One 90° elbow = 7' (2.1 m)

One 90° elbow = 9.3' (2.83 m)

One 90° elbow = 11.6' (3.5 m)

One 90° elbow = 14' (4.3 m)

Equivalent Length (feet) (m) =

1.17 x Duct Diameter (inches) (cm)

- Drying Tumblers JCB75CG Drying Tumblers SC75CSH Drying Tumblers SC50CG Drying Tumblers JCB30WE Drying Tumblers JCB30CSH Drying Tumblers JC50EG Drying Tumblers SC75CG Drying Tumblers JCB50CG Drying Tumblers SCB50CSH Drying Tumblers SCB30CSL Drying Tumblers JCB30CSL Drying Tumblers JCB30XG Drying Tumblers SC50CE Drying Tumblers JCB50CSH Drying Tumblers JCB75CE Drying Tumblers JC75CSH Drying Tumblers JCB30CG Drying Tumblers SCB30CE Drying Tumblers JCB50CE Drying Tumblers JCB30CE Drying Tumblers SCB30CG Drying Tumblers SCB75CG Drying Tumblers SC50EG Drying Tumblers JC75CG Drying Tumblers SC50CSH Drying Tumblers JC75CE Drying Tumblers SCB50CE Drying Tumblers SCB75CSH Drying Tumblers JC50CE Drying Tumblers JC50CSH Drying Tumblers SCB75CE Drying Tumblers SCB30XG Drying Tumblers JC50CG Drying Tumblers SC75CE Drying Tumblers JCB75CSH Drying Tumblers SCB50CG Drying Tumblers JCB50EG Drying Tumblers SCB30WE