Lubrication – Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 35

For Machines Mfg. Since 8/09

Model SB1021/SB1022

-33-

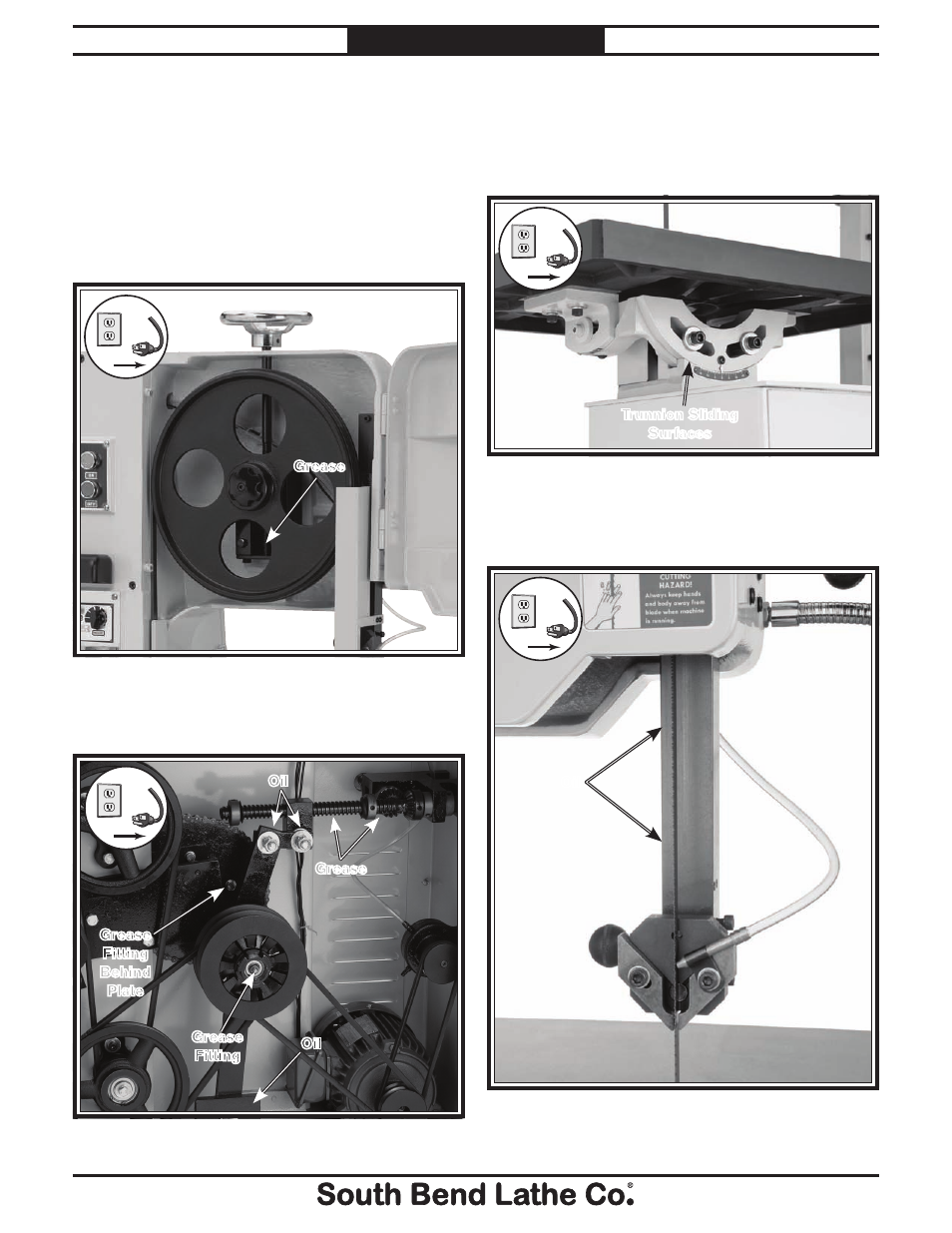

M A I N T E N A N C E

If the table becomes difficult to tilt, position

it so that you can brush a thin coat of multi-

purpose grease on the trunnion sliding surfaces

(see Figure 36), then move back-and-forth to

distribute.

Lubrication

The bearings on your bandsaw are factory

lubricated and sealed. Leave them alone unless

they need to be replaced.

When needed, brush a light coat of multi-purpose

grease on the blade tension leadscrew (Figure

34).

Use multi-purpose grease and a light machine oil

where in Figure 35.

Figure 35. System lubrication points.

Grease

Fitting

Oil

Grease

Grease

Fitting

Behind

Plate

Oil

!

Figure 34. Upper wheel leadscrew lubrication.

Grease

!

The sliding surfaces on the guide post may

occasionally need to be lubricated with a light

machine oil if the movement becomes stiff.

Figure 37. Guide post lubrication.

Oil

!

Figure 36. Trunnion lubrication.

Trunnion Sliding

Surfaces

!