Chip inspection chart blade speed chart – Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 27

For Machines Mfg. Since 8/09

Model SB1021/SB1022

-25-

O P E R A T I O N

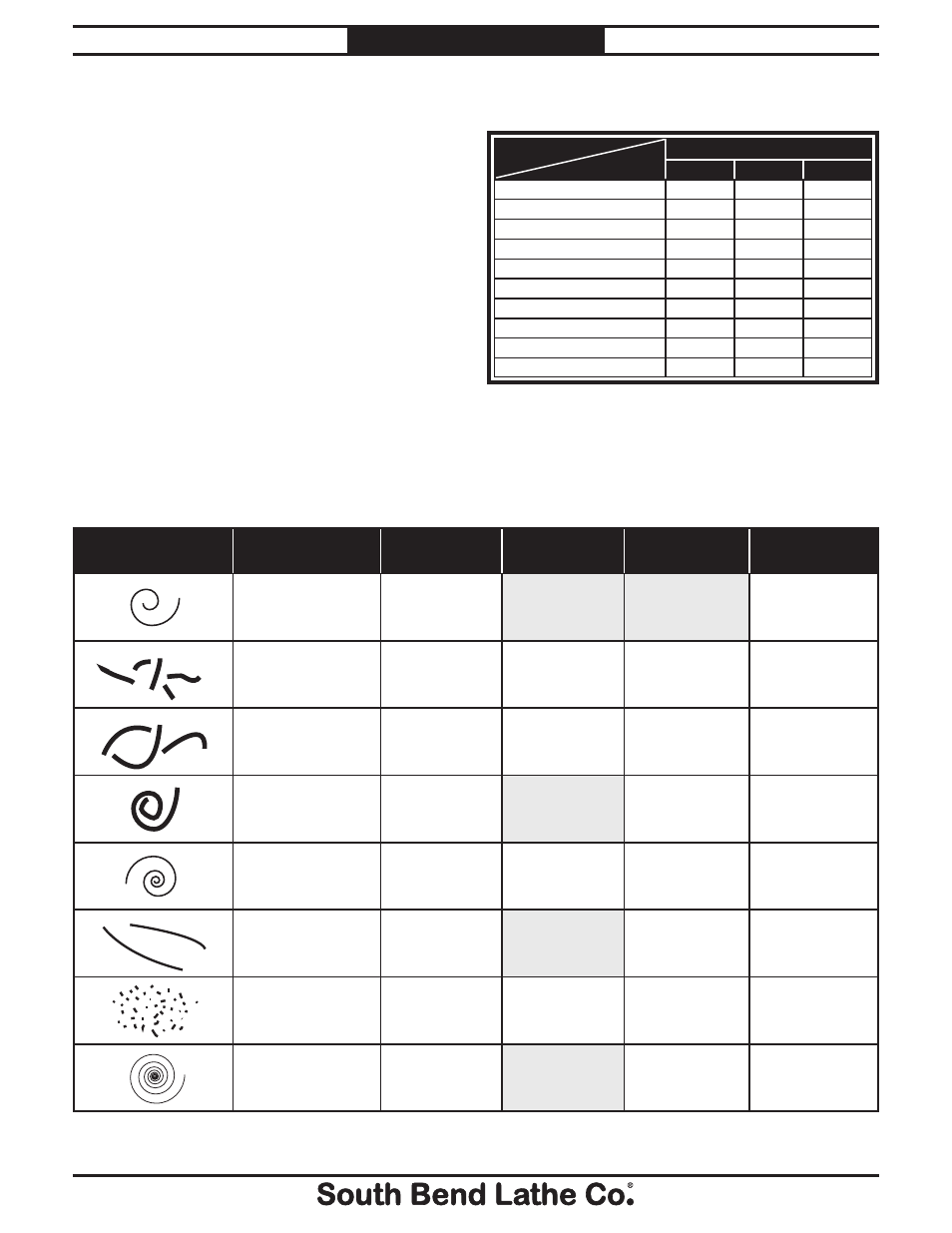

Use the blade speed chart in Figure 15 to

determine an appropriate speed to start with,

then examine the chips once you start cutting to

determine which way to adjust the speed or your

feed rate.

The best method for evaluating the cutting speed and feed rate for an operation is to inspect the chips

created by the cut. Refer to the chip inspection chart below for chip inspection guidelines.

Chip

Appearance

Chip

Description

Chip

Color

Blade

Speed

Feed

Pressure

Other

Actions

Thin & Curled

Silver

Good

Good

Hard, Thick &

Short

Brown or Blue

Increase

Decrease

Hard, Strong &

Thick

Brown or Blue

Increase

Decrease

Hard, Strong &

Thick

Silver or Light

Brown

Good

Decrease

Slightly

Check Blade

Pitch

Hard & Thin

Silver

Increase

Decrease

Check Blade

Pitch

Straight & Thin

Silver

Good

Increase

Powdery

Silver

Decrease

Increase

Curled Tight & Thin

Silver

Good

Decrease

Check Blade

Pitch

Figure 16. Chip inspection chart.

Chip Inspection Chart

Blade Speed Chart

Figure

15. Dry cutting blade speed chart.

Alloy Steel

90

125

160

Aluminum

185

250

315

Brass (Soft)

375

500

625

Brass (Hard)

150

200

250

Bronze

150

200

250

Copper

185

250

315

Cast Iron

90

125

160

High Speed Steel

35

50

65

Low Carbon Steel

90

125

160

Medium Carbon Steel

75

100

125

Material

Thickness

0 - 1/2"

1/2" - 1"

1" +

Dry Cutting Speed (FPM)