Maintenance schedule, Cleaning, Dressing grinding wheel – Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 34

MAINTENANCE

-32-

For Machines Mfg. Since 8/09

Model SB1021/SB1022

M A I N T E N A N C E

Maintenance Schedule

For optimum performance from your machine,

follow this maintenance schedule and refer to

any specific instructions given in this section.

Daily:

s

#HECKCORRECT

s

Check/correct damaged or dull saw blade.

s

Check/correct worn or damaged wires.

s

Clean/protect table.

s

#LEAN

s

Correct any other unsafe condition.

Monthly:

s

#HECK

s

,UBRICATE

s

2EMOVE

Yearly:

s

Open rear lower cover, inspect belts, and

tighten all fasteners (see Page 34).

Use a brush and a shop vacuum to remove chips

and other debris from the machine. Keep the

table rust-free with regular applications of a high

quality anti-rust product.

Once a month, remove the blade and thoroughly

clean all metal chips or oil from the wheel

surfaces. Redress the rubber tires if the become

glazed.

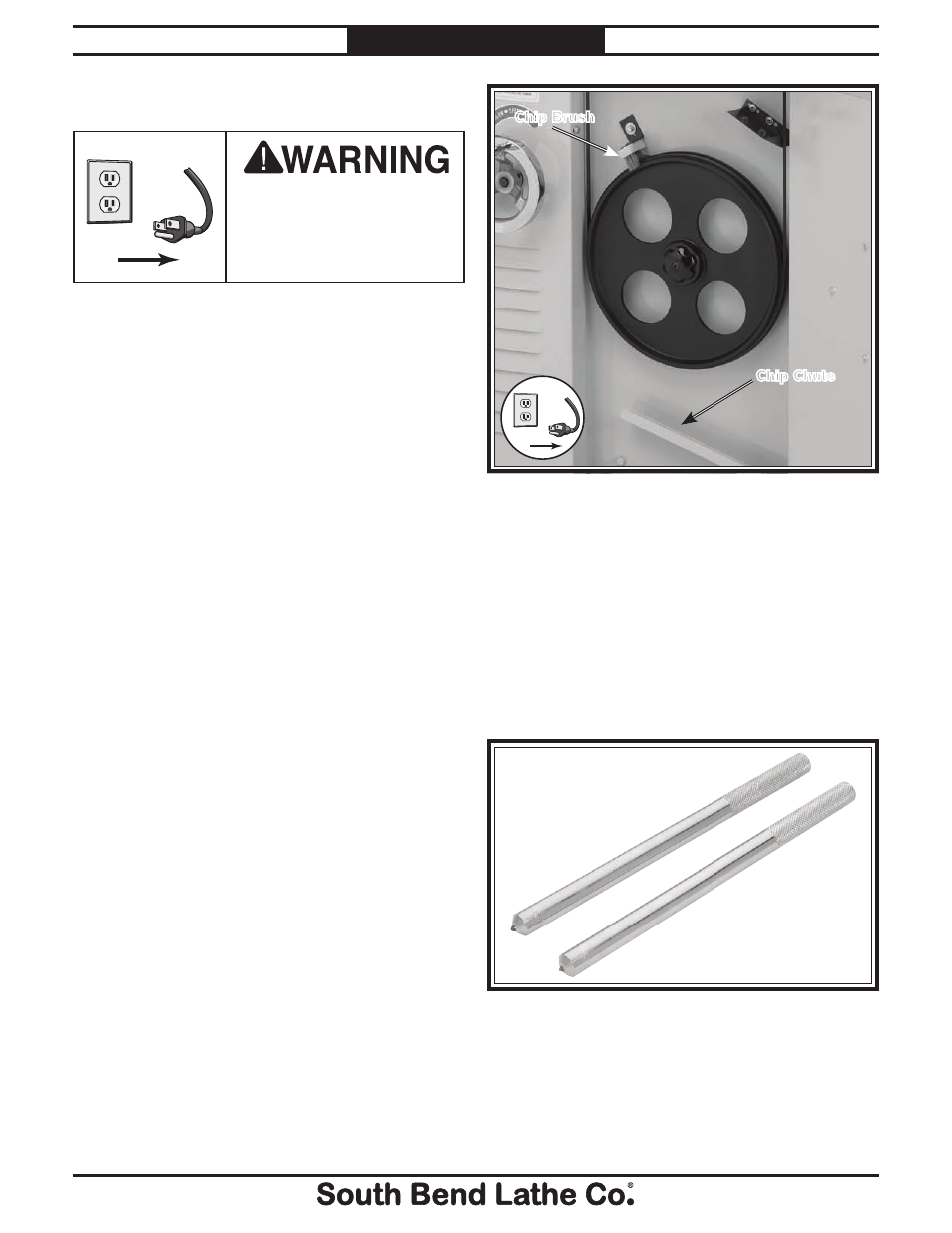

When cleaning the wheel areas, empty and clean

the chip chute and brush (Figure 32).

Cleaning

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

Figure 32. Lower wheel and chip chute.

Chip Chute

Chip Brush

!

Dressing Grinding

Wheel

Periodically dress the grinding wheel to square

it up and renew the abrasive surface. Dressing

is done in the same manner as a typical grinding

operation but using a diamond-tipped dressing

tool (see Figure 33).

Figure 33. Example of diamond dressing tools.