Tilting table, Blade welding – Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 30

-28-

For Machines Mfg. Since 8/09

Model SB1021/SB1022

O P E R A T I O N

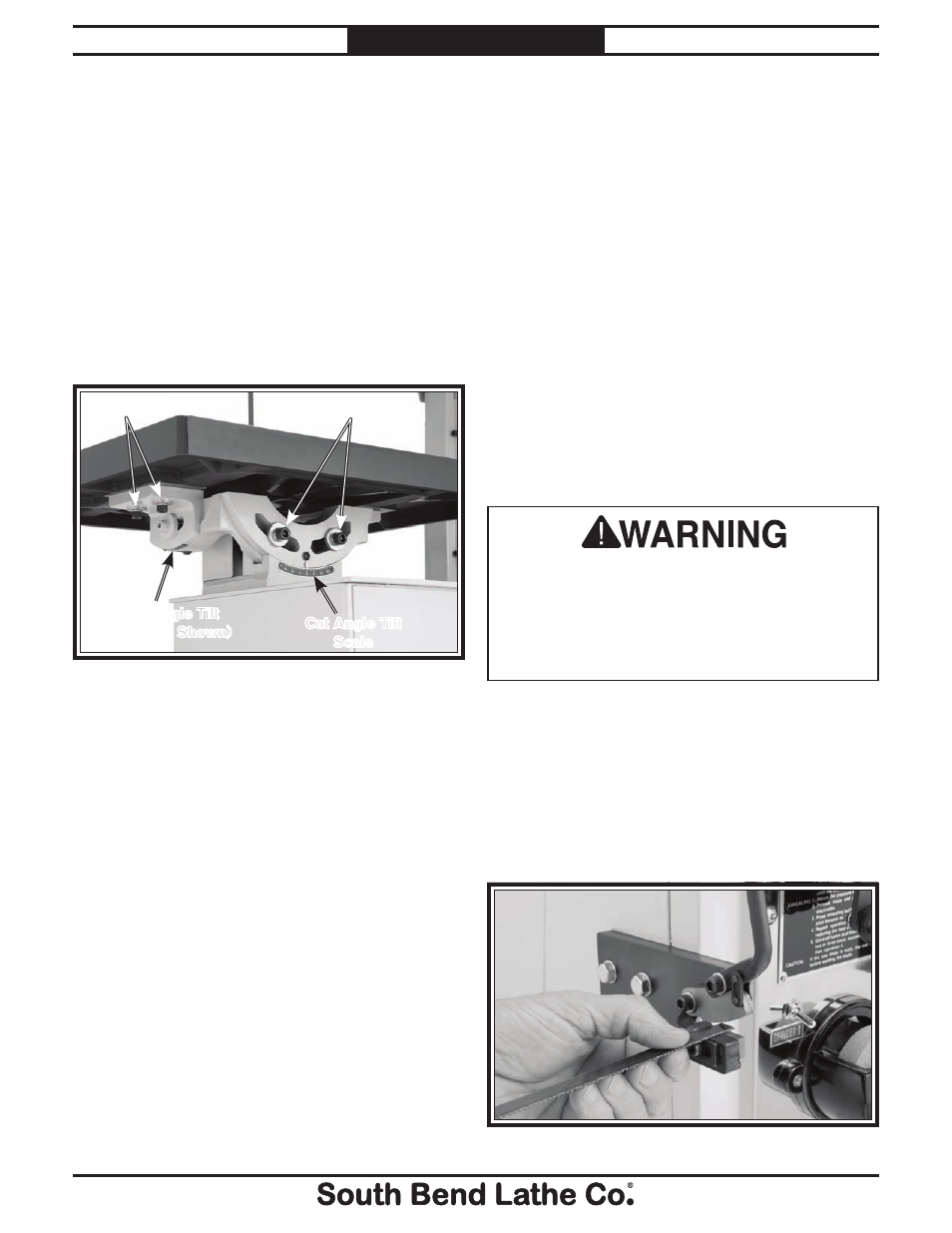

To tilt the table forward or backward:

1. DISCONNECT BANDSAW FROM POWER!

2. Use a 6mm hex wrench to loosen both sets

of cap screws on the two feed angle tilt scale

brackets (see Figure 23).

3. Using the two scales, adjust the angle of the

table for cutting a compound angle, then re-

tighten the cap screws.

Tilting Table

The bandsaw table tilts 15° to the left and 15° to

the right for basic cut angles, and 10° to the front

and 10° to the back for feed angles. When used

together, compound angled cuts can be made.

To tilt the table left or right:

1. DISCONNECT BANDSAW FROM POWER!

2. Use an 8mm wrench to loosen the two cap

screws on the cut angle trunnion underneath

the rear of the table (see Figure 23).

3. Using the cut angle tilt scale, adjust the

angle of the table for your operation, then re-

tighten the cap screws.

Figure 23. Table tilt adjustment controls.

Cut Angle Tilt

Scale

Feed Angle Tilt

Scale (One Shown)

Cap Screws

Cap Screws

Being able to quickly and safely weld a bandsaw

blade comes in handy for the following situations:

s

4O

s

4O

s

4O

Your metal cutting bandsaw is equipped with a

blade welder that uses electrical current to heat

and fuse the blade ends together. This process

will leave the joint brittle, so an annealer is

also included to give the blade strength and

flexibility.

Blade Welding

To weld the ends of blade together:

1. Turn the bandsaw motor OFF.

2. Place the blade evenly against the back of

the blade shear and firmly pull the handle

down to square off the blade end (see Figure

24).

Figure 24. Using the blade shear to cut the blade.

The electric current that flows through the

blade welder during operation could cause

serious personal injury or death. To reduce

the risk of electrocution or burns, never touch

any metal part of the welding station or blade

during welding or annealing.