Blade pitch (tpi) – Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 24

-22-

For Machines Mfg. Since 8/09

Model SB1021/SB1022

O P E R A T I O N

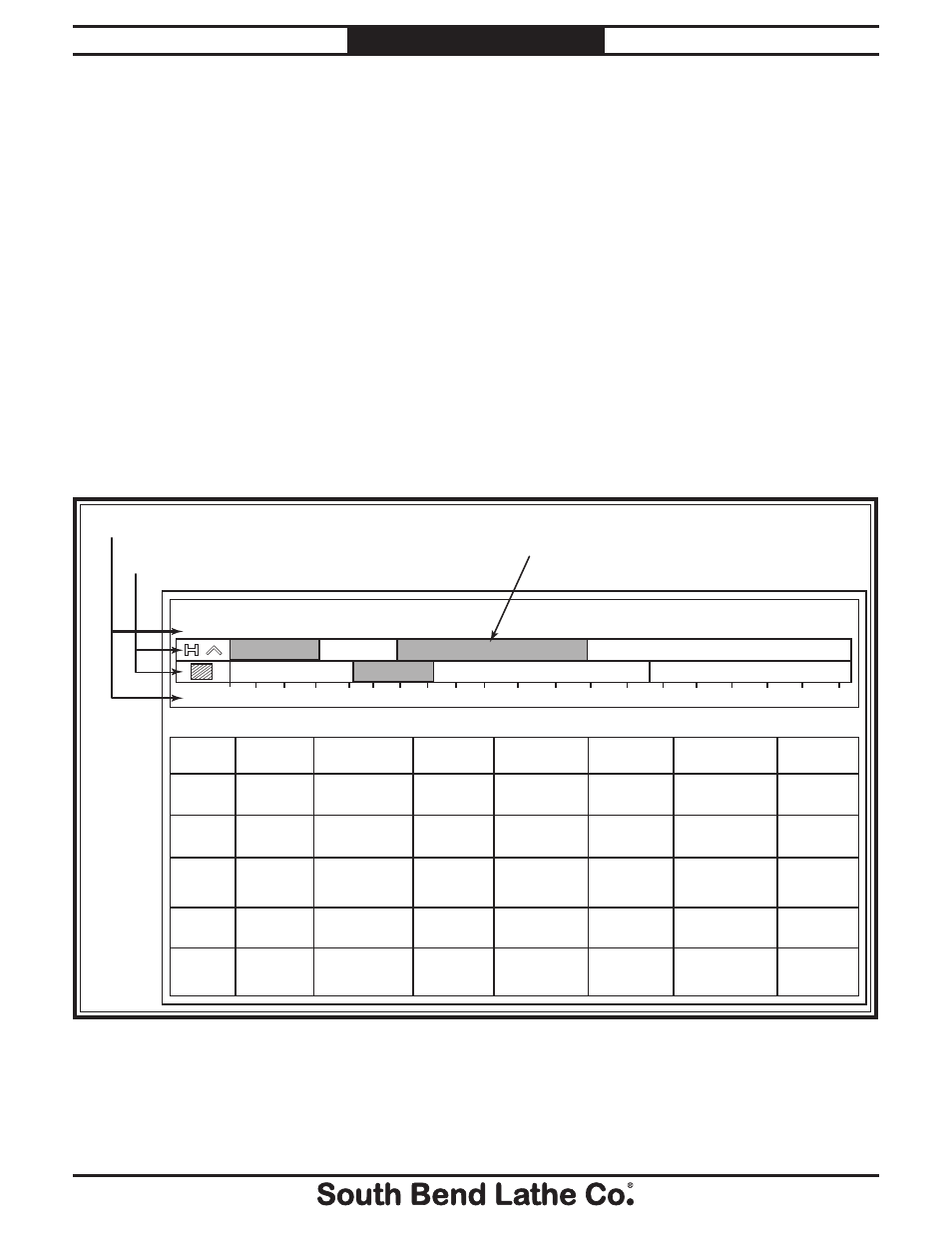

Blade Pitch (TPI)

The chart below is a basic starting point for

choosing teeth per inch (TPI) for variable pitch

blades and standard raker set bi-metal blades/

HSS blades. However, for exact specifications

of bandsaw blades that are correct for your

operation, contact the blade manufacturer.

To select the correct blade pitch:

1. Measure the material thickness. This

measurement is the length of cut taken

from where the tooth enters the workpiece,

sweeps through, and exits the workpiece.

2. Refer to the "Material Width/Diameter"

row of the blade selection chart in Figure

13, and read across to find the workpiece

thickness you need to cut.

3. Refer to the "Material Shapes" row and find

the shape of the material to be cut.

4. In the applicable row, read across to the

right and find the box where the row and

column intersect. Listed in the box is the

minimum TPI recommended for the variable

tooth pitch blades.

5. The "Cutting Speed Rate Recommendation"

section of the chart offers guidelines for

various metals, given in feet per minute

(FPM). Choose the speed closest to the

number shown in the chart.

CUTTING SPEED RATE RECOMMENDATION

TOOTH SELECTION

50

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

2

1

/

2

3

1

/

2

75

100

150

200

250

300

350

400

2/3

2/3

1.4/2.5

1.5/.8

3/4

3/4

4/6

5/8

450

mm

inch

Copper

Alloy

229~482

(70) (147)

203~213

(62) (65)

85~203

(26) (62)

220

(67)

220~534

(67) (163)

203

(62)

85

(26)

321

(98)

180~220

(54) (67)

95~213

(29) (65)

242

(75)

65~85

(20) (26)

180~220

(54) (67)

75~118

(25) (36)

246

(75)

108~225

(33) (75)

196~354

(60) (108)

203

(62)

111~321

(34) (98)

150~203

(46) (62)

Aluminum

Alloy

Thin

Tube

Angle

Steel

Carbon

Steel

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Speed FPM

(M/Min)

Material

Material

Material

Material

Tool Steel

Mold Steel

High-Speed

Tool Steel

Alloy

Steel

Water

Hardened

Tool Steel

Stainless

Steel

CR Stainless

Steel

Free Machining

Stainless Steel

Gray

Cast Iron

Ductile

Austenitic

Cast Iron

Malleable

Cast Iron

Plastics

Cold-Work

Tool Steel

Hot-Work

Tool Steel

Oil~Hardened

Tool Steel

Material Width/Diameter

Material Shapes

Teeth Per Inch (TPI) for Variable Pitch Blades

Figure 13. General guidelines for blade selection and speed chart.