Southbend 14" METAL CUTTING BANDSAW SB1022 User Manual

Page 33

For Machines Mfg. Since 8/09

Model SB1021/SB1022

-31-

O P E R A T I O N

17. Re-clamp the blade in the welding clamps

with the joint centered, then repeat the

annealing process twice more. Each time

gradually reduce the amount of time you

anneal the weld.

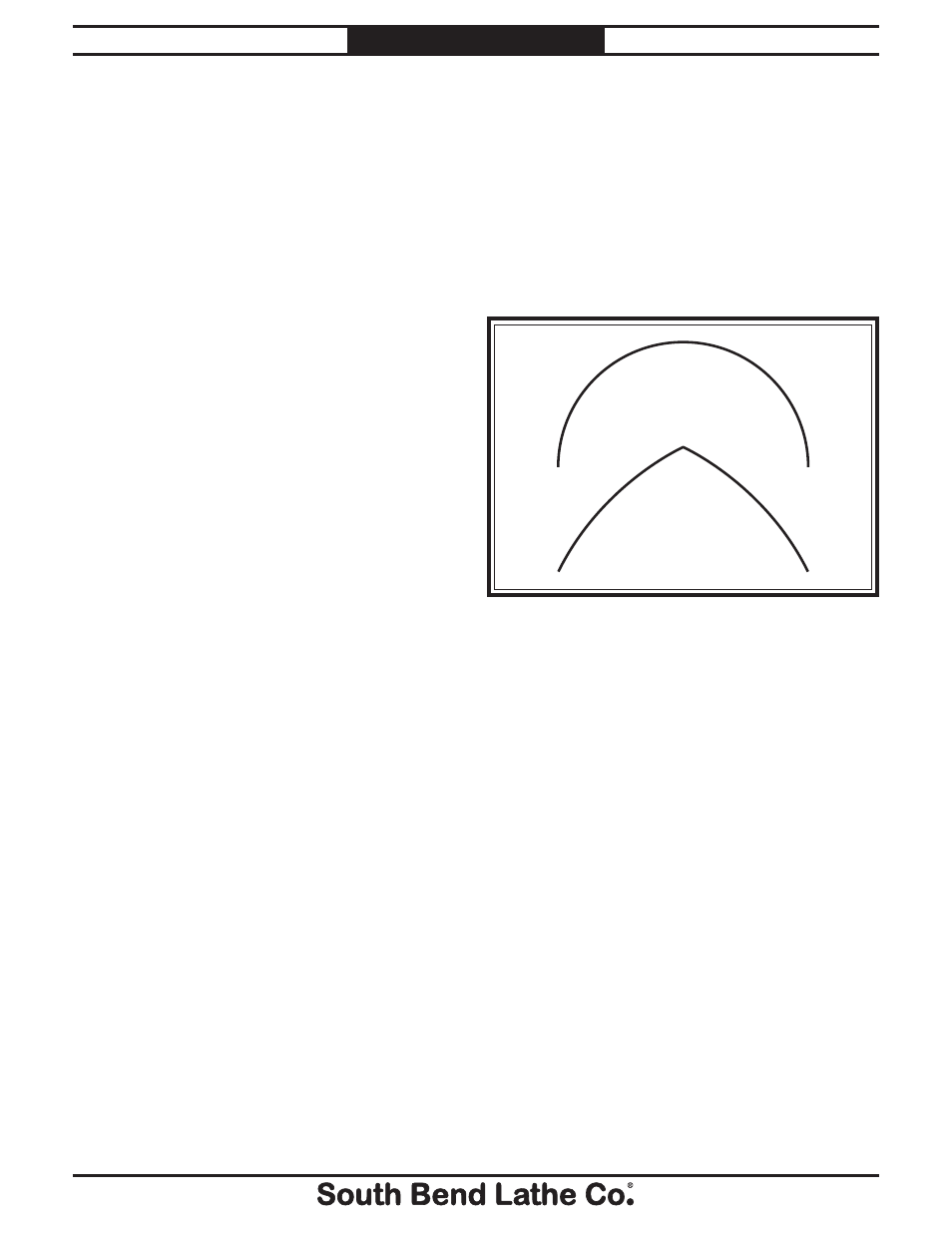

18. Test the strength and flexibility of the weld

by bending the blade in an arc similar to that

of the bandsaw wheels. The blade should

bend in a smooth circular, rounded shape—

rather than a pointed fold (see Figure 31).

Correct

Not Correct

(Cut and reweld)

Figure 31. Correct blade weld bend for strength and

flexibility.

13. Press and hold the annealing button until

the weld zone turns the appropriate color,

then release the button.

Note:

If you cannot get the proper annealing

color from the blade manufacturer, use the

recommendations below as a baseline and

experiment from there.

—Carbon Steel ..................... Dull Cherry Red

—Carbon Steel Hard Back ...................... Blue

—Bi-Metal ........................................... Orange

—High Speed Steel .............. Dull Cherry Red

14. Repeat Step 13 three to four more times,

allowing the weld to cool for about 30

seconds between each repetition. Each time

reduce the amount of time you press the

anneal button, to reduce the amount of heat

successively.

15. Allow the blade to cool, then re-inspect the

weld.

16. Grind away the weld bead on the top and

bottom of the joint so that the blade is flat

and will run smoothly on the wheels and

between the blade guides.

Note:

Make sure not to grind the teeth or

blade body, or overheat the blade during

grinding—this will weaken the blade. A

small amount of ticking is acceptable during

cutting operations.