Siemens Albatros Zone Controler CE1U2353en01a User Manual

Page 18

18/26

Siemens Schweiz AG

User Manual OEM

CE1U2353en01a

HVAC Products

The settings in detail 22.

November

2006

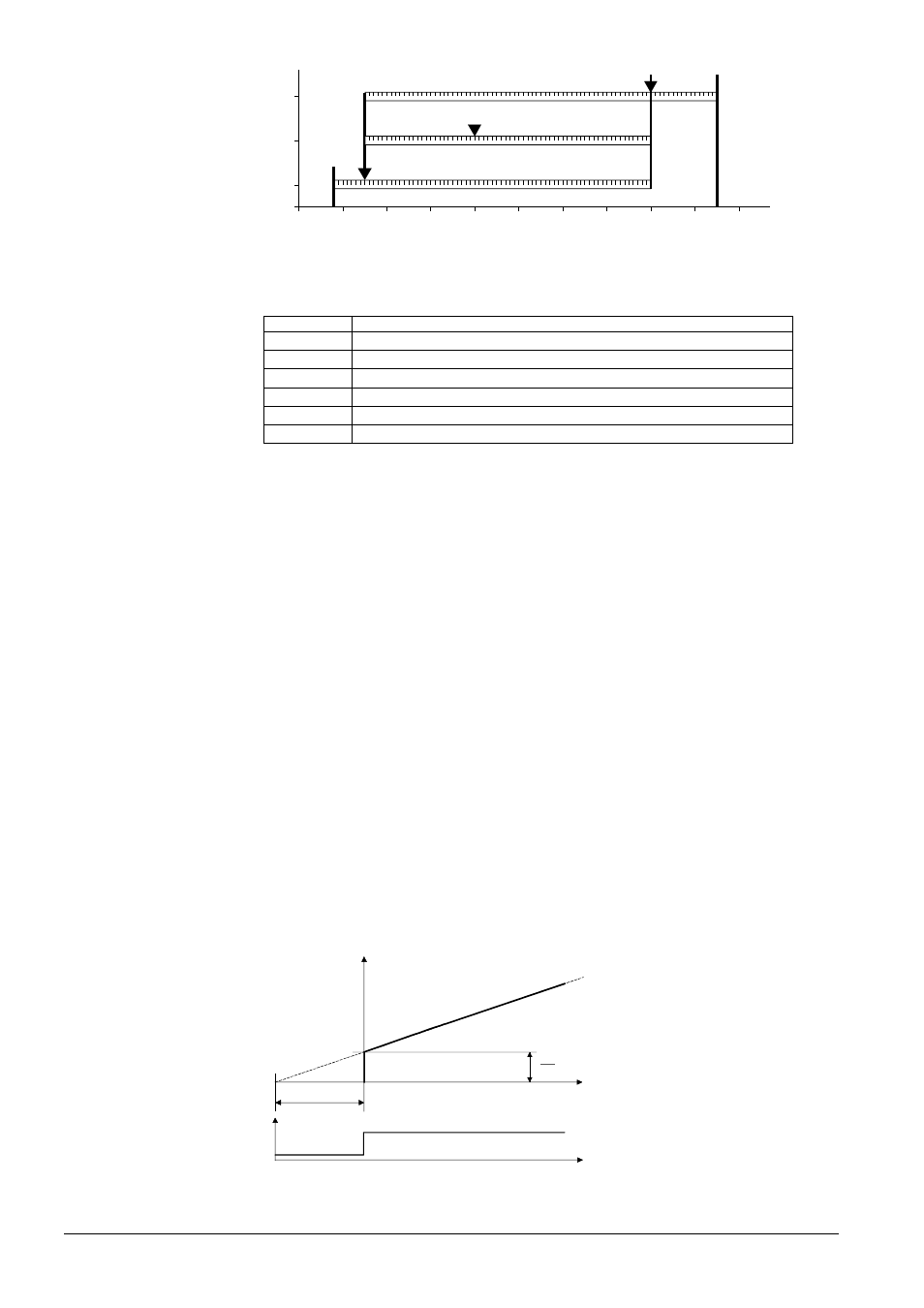

0 10 20 30 40 50 60 70 80 90 100

TV

max

min

akt

°C

2358

Z

09

TVw

TVmin

TVmax

TVw

Current flow temperature setpoint

TVmax

Flow temperature setpoint maximum

Tvmin

Flow temp setpoint min

mixing valve control

Line no.

Operating line

2130 Mixing

valve

boost

2132 Actuatortype

2133

Switching differential 2-pos

2134

Actuator running time

2135 Mixing

valve

Xp

2136 Mixing

valve

Tn

For mixing, the actual value of the boiler flow temperature must be higher than the

required setpoint of the mixing valve flow temperature since otherwise that temperature

cannot be controlled. The controller generates the boiler temperature setpoint based on

the increase set here and the current flow temperature setpoint.

Selection of the type of actuator determines the way the control action impacts the type

of mixing valve actuator used.

For the 2-position actuator, the 2-position switching differential must also be adapted.

This is not required when using 3-position actuators.

Setting the actuator running time for the mixing valve used.

The proportional band defines within which change of the control variable

∆x (∆T of the

flow) the whole correcting span y (valve travel) is traversed.

The smaller the proportional band, the greater the change of the manipulated variable

∆y at a given change of the controlled variable ∆x.

The integral action time is the period of time the controller’s I-part would require to

produce the same change of the manipulated variable as the P-part

An adjustment of the integral action time changes the valve’s rate of response.

The longer the integral action time Tn, the slower the response of the controlled

system.

239

2

Z

08

Tn

y

t

Xp

1

t

x

Mixing valve boost

Actuator:type

Switching differential 2-

pos

Actuator: running time

Mixing valve Xp

Mixing valve Tn