System grounding – Woodstock SHOP FOX W1816 User Manual

Page 36

-34-

W1816 Owner's Manual (Mfg. Since 10/09)

O

PE

R

ATIO

NS

System Grounding

Since plastic hose is abundant, relatively inexpensive,

easily assembled and air tight, it is a very popular

material for conveying dust from woodworking machines

to the dust collector. However, plastic flex-hose

and plastic duct are an insulator, and dust particles

moving against the walls of the plastic duct create a

static electrical build up. This charge will build until

it discharges to a ground. If a grounding medium is

not available to prevent static electrical build up, the

electrical charge will arc to the nearest grounded source.

This electrical discharge may cause an explosion and

subsequent fire inside the system.

To protect against static electrical build up inside a non-

conducting duct, a bare copper wire should be placed

inside the duct along its length and grounded to the dust

collector. You must also confirm that the dust collector

is continuously grounded through the electrical circuit to

the electric service panel.

If you connect the dust collector to more than one

machine by way of a non-conducting branching duct

system and blast gates, the system must still be

grounded as mentioned above. We recommend inserting

a continuous bare copper ground wire inside the entire

duct system and attaching the wire to each grounded

woodworking machine and dust collector.

Be sure that you extend the bare copper wire down all

branches of the system. Do not forget to connect the

wires to each other with wire nuts when two branches

meet at a “Y” or “T” connection.

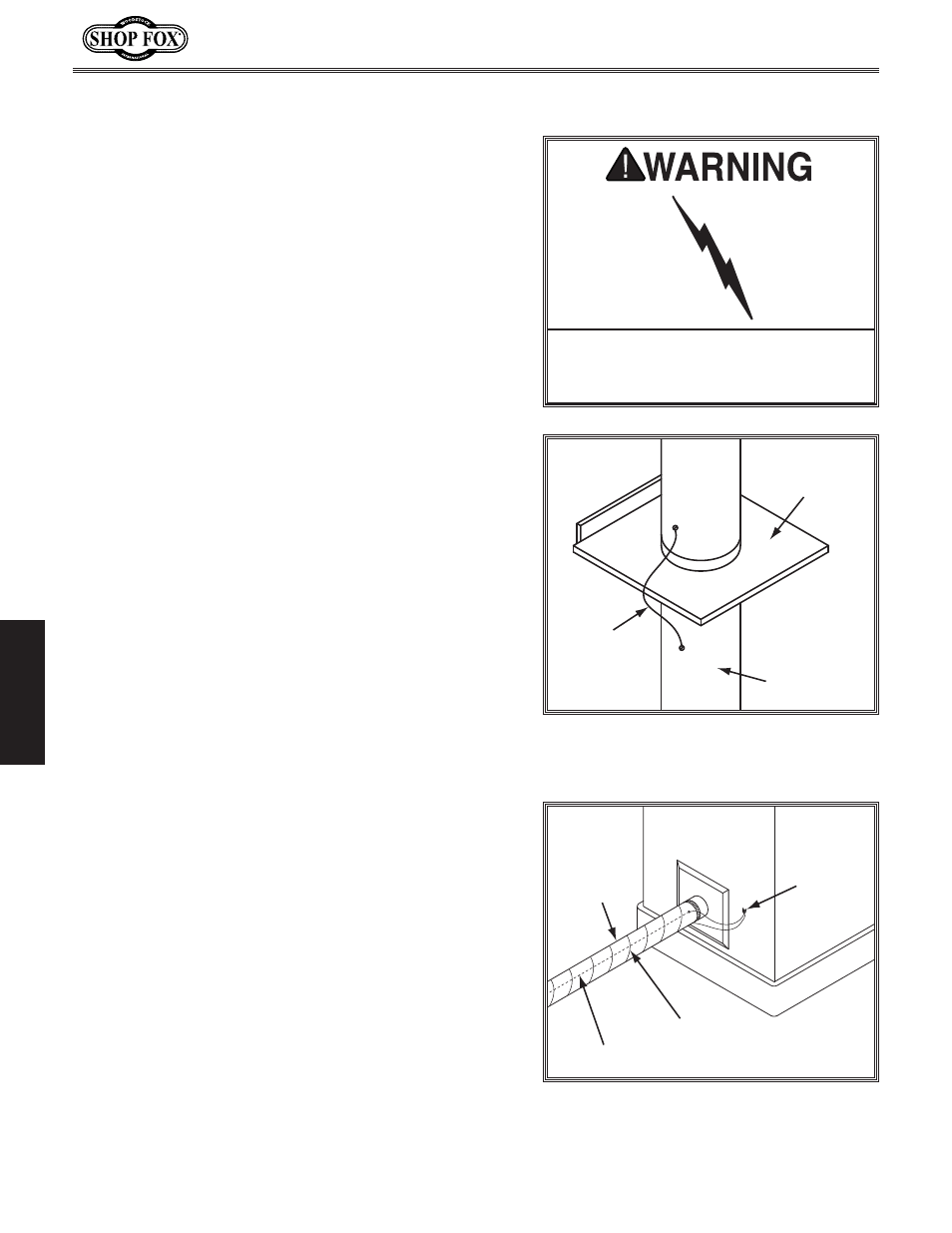

Ensure that the entire system is grounded. If using plastic

blast gates to direct air flow, the grounding wire must be

jumped (see

Figure 50) around the blast gate without

interruption to the grounding system.

We also recommend wrapping the outside of all plastic

ducts with bare copper wire to ground the outside of the

system against static electrical build up. Wire connections

at Y’s and T’s should be made with wire nuts.

Attach the bare ground wire to each stationary

woodworking machine and attach to the dust collector

frame with a ground screw as shown in

Figure 51. Ensure

that each machine is continuously grounded to the

grounding terminal in your electric service panel.

ALWAYS guard against static electrical

build-up by properly grounding all dust

collection lines.

Copper

Ground

Wire

Plastic Blast

Gate

Metal Duct

Figure 50. Jumper wire connected to both

sides of a plastic blast gate and metal

ducts.

External Ground Wire

Internal Ground Wire

Flex

Hose

Ground

Screw

Figure 51. Example of a plastic flexible

hose grounded to the machine.