System design – Woodstock SHOP FOX W1816 User Manual

Page 29

-27-

W1816 Owner's Manual (Mfg. Since 10/09)

O

PE

R

ATIO

NS

Step 1: Decide Who Will Design

For most small-to-medium sized shops, you can design

and build the dust collection system yourself without

hiring engineers or consultants. We have included some

information here to get you started on a basic design.

If you have a large shop or end up designing a

complicated system, then we recommend that you do

additional research beyond this manual, or that you seek

the help of an expert.

Step 2: Sketch Your Shop Layout

When designing a successful dust collection system,

planning is the most important step. In this step, you

must sketch a basic layout of your shop.

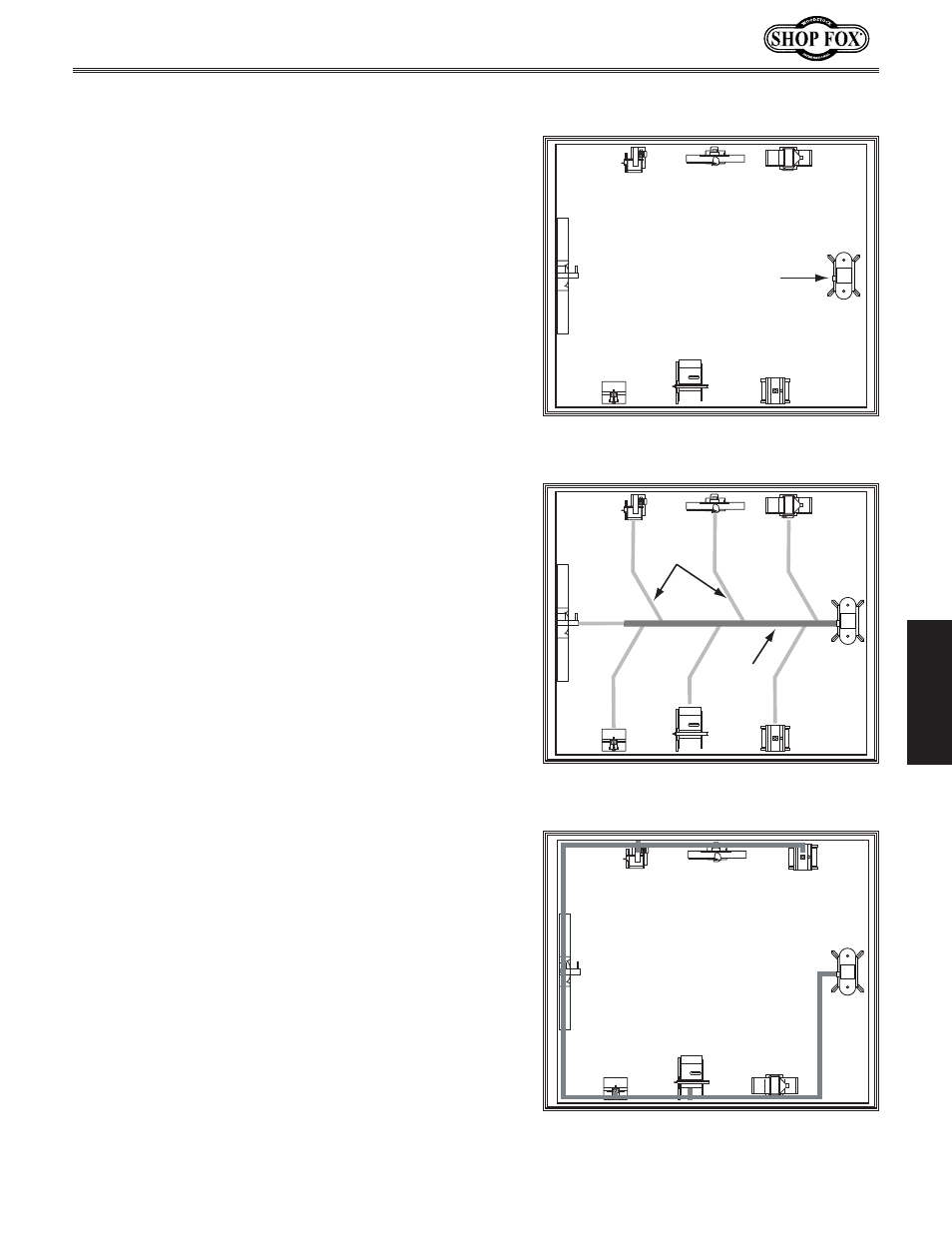

Your sketch only needs the basic details of the shop

layout, similar to

Figure 37, including all your current/

planned machines and your planned placement of the

dust collector.

Step 3: Sketch a Basic Duct Layout

For the next step, sketch how you will connect your

machines to the dust collector. Consider these general

guidelines for an efficient system:

1. Machines that produce the most saw dust should be

placed nearest to the dust collector (i.e. planers and

sanders).

2. Ideally, you should design the duct system to have

the shortest possible main line and secondary

branch ducts. See

Figures 38–39 for ideas of good

duct layouts versus bad duct layouts.

System Design

Dust Collector

Figure 37. Example of initial shop layout

sketch.

Main

Line Duct

Branch

Line Ducts

GOOD

Figure 38. Example of a good basic duct

layout.

BAD

Figure 39. Example of a bad basic duct

layout.